Rockwell Hardness Testers

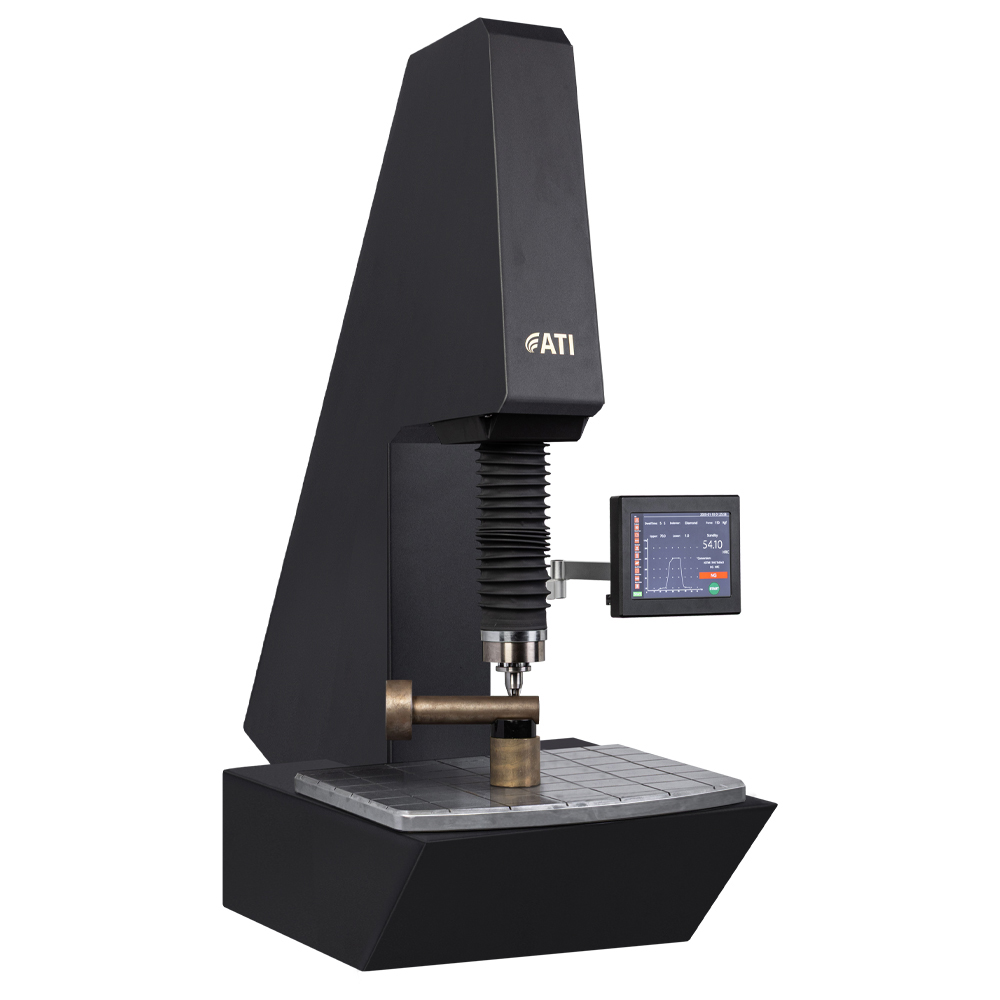

ATI MRS

Fully motorized and automatic for Rockwell and Superficial Rockwell

Fully motorized and automatic hardness tester for Rockwell and Superficial Rockwell measurements. Automatic test cycle with one START button measurement: automatic vertical stroke, automatic contact and recognition of sample surface, automatic clamping system with the sample during the entire test cycle, and automatic hardness measurement. Once the test cycle is completed, the result will appear on the side screen.

ATI RS

Fully automatic for Rockwell and Superficial Rockwell

Automatic hardness tester for Rockwell and Superficial Rockwell hardness measures. The elevanting screw is manually adjusted to bring the sample into the testing area, after which the measurement cycle will automatically start, recognizing the sample surface to be tested. Once the test cycle is completed, the result will appear on the side screen.

ATI HTR

Fully motorized and automatic

Fully automatic Rockwell hardness tester for accurate measurement of ferrous, non-ferrous metals, and non-metal materials. ATI HTR is characterized by a motorized vertical stroke that automatically descends, recognizing the surface to be tested. It is possible to follow the test cycle step by step via the side panel.

ATI IN

Manual

The ATI IN is a Rockwell hardness tester with built-in image viewing. Its indenter is designed for measuring hardness on components with deep cavities, such as rings, tubes, and parts near flanges or shoulders (minimum internal test diameter of 25 mm). With just one START button, the measurement begins automatically and the results appear directly on the built-in screen.

AFFRI 3332 MRSA

Fully motorized and automatic

The AFFRI MRS Series Rockwell hardness testers are fully motorized bench instruments that provide automated, precise testing in compliance with ASTM and ISO standards. They offer exceptional accuracy and are suitable for testing a wide range of materials, including metals and plastics, in various treatments like hardening and nitriding.

AFFRI DAKOMASTER 300

Fully automatic

AFFRI DAKOMASTER 3000 is a Rockwell hardness tester with fully automatic test cycle for Rockwell, Superficial Rockwell, Brinell, Vickers, and Shore tests. It’s comlòiance with ASTM and ISO hardness standards. This hardness tester is a top-level bench hardness tester with a wide touchscreen allowing easy test planning and a clear view of results.

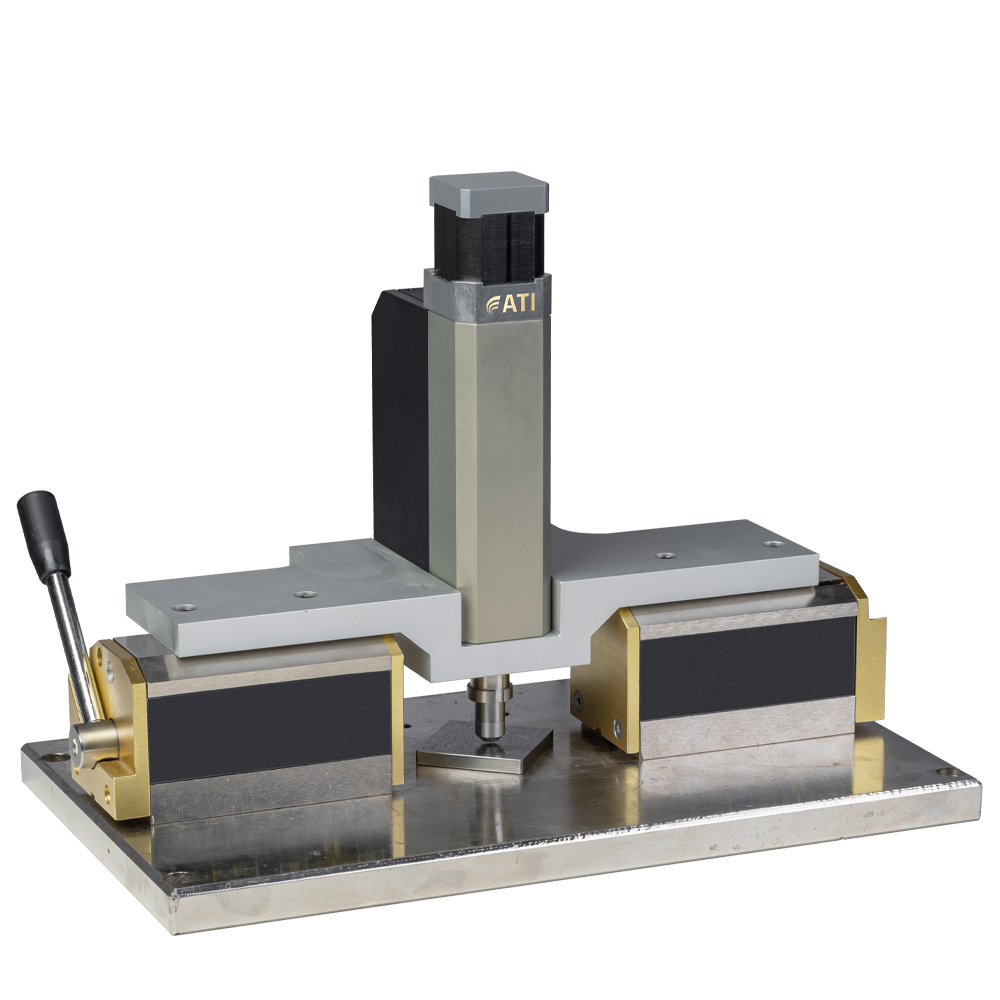

AFFRI PRS

Fully automatic

Complete automatic hardness test cycle including the clamping of the piece, application of the load, hardness measurement, release of the piece, return to starting point and it is ready for a new test. High volume measurements, the tester can easily be introduced into the conveyor lines, yielding up to 1500 test per hour.

AFFRI 250 DRM

Semi-automatic

The Rockwell Hardness Tester 250 DRM is a semi-automatic, user-friendly device designed for testing hardness on HRC, HRB, HRA, and other scales, with test loads ranging from 3 to 250 kgf. It supports Rockwell, Superficial Rockwell, and Brinell HBWT hardness tests, fully complying with all relevant hardness testing standards, including ASTM E10 – E18 and ISO 6506 – 6508.

AFFRI RSD serie

Manual

AFFRI Rockwell RSD hardness testers support various scales, including HRC, HRB, HRA, and others, with test loads ranging from 3 to 250 kgf. They perform Rockwell, Superficial Rockwell, and Brinell HBWT hardness tests, complying with ASTM E10, E18, E103, and ISO 6506, 6508 standards. Ideal for testing metals, alloys, and other materials, they provide precise and fast results, optimizing production processes.

Brinell Hardness Testers

ATI B3000

Fully automatic with turret at 5 positions

ATI B3000 is an automatic Brinell hardness tester with one START button to get start the entire automatic Brinell test cycle. ATI B3000 is equipped with a multi-position automatic turret at 5 steps: 3 indenters for Brinell hardness tests and 2 optical lenses (20X and 40X) for indentation reading. The turret rotates 360° horizontally.

EASYDUR INTEGRAL 1

Fully automatic

EASYDUR INTEGRAL 1 is a Brinell hardness tester with fully motorized and automatic test cycle, not affected by operator influences. Test loads from 1kg to 3000 kg. Vertical capacity 500 mm /20″ and horizontal capacity 170 mm /6.5″. Milling station is built-in for sample preparation.

EASYDUR INETGRAL REVOLVER

- Fully motorized and automatic with turret at 8 slots.

- Milling station for sample preparation.

EASYDUR INTEGRAL REVOLVER is a fully motorized and automatic universal hardness tester with motorized turret at 8 slots : equipped with different hardness scales indenters, different optic lens, laser and a milling station for sample surface preparation before the indentation.

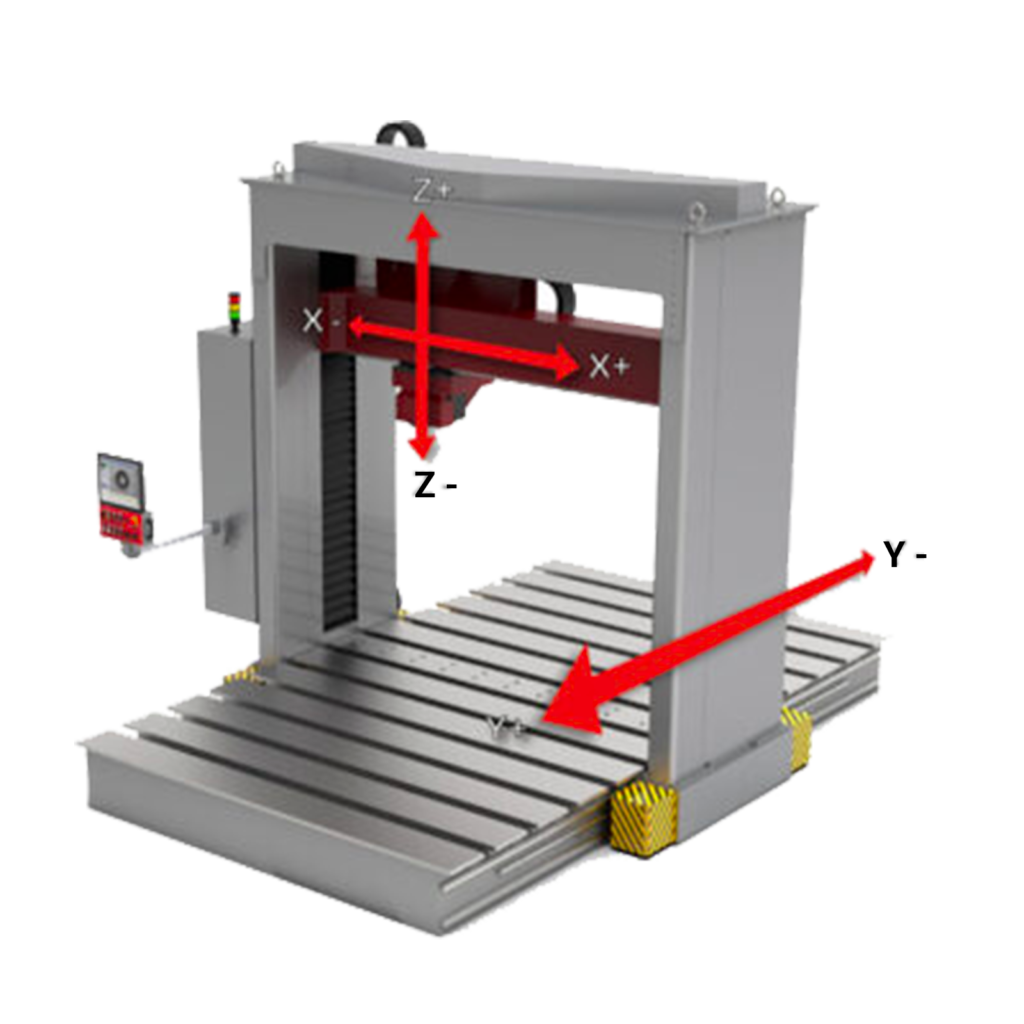

EASY PORTAL by EASYDUR

EASY PORTAL is an automatic CNC Portal Hardness Tester for very big parts. Suitable for forges, heat treatment and steel factories.Test loads from 10 kg to 3000 kg. The table (6000 mm long) is fixed and stable and has no weight or sample size limitations.

Vickers Hardness Testers

ATI V AUTO

Fully automatic with turret at 5 positions

ATIV AUTO is an automatic Vickers, micro Vickers, and Knoop hardness tester. Just on START button to get start the automated hardness test cycle. ATIV AUTO has a 5-position automatic turret for automatic selection of each tool and it ‘s equipped with motorized X-Y-Z table and auto-focus. Can support multi-indentation cycles and automatic specimen scanning.

ATI V

Manual with turret at 5 positions

ATIV is a manual Vickers, micro Vickers, and Knoop hardness tester. ATIV has a 5-position automatic turret for automatic selection of each tool and it ‘s equipped with manual X-Y table and manual knob to manually adjust the table and the elevating screw. Can support multi-indentation cycles and automatic specimen scanning.

ATI DM2

Manual with turret at 3 positions

ATI DM2 is a manual Vickers hardness tester with manual knob to control the elevating screw. ATI DM2 is equipped with 3-position automatic turret (1 indenter and 2 objective lenses) with automatic selection of the combination. The manual focus control uses a knob to adjust the Z-axis with extreme precision, ensuring accurate focusing through the long elevation screw.

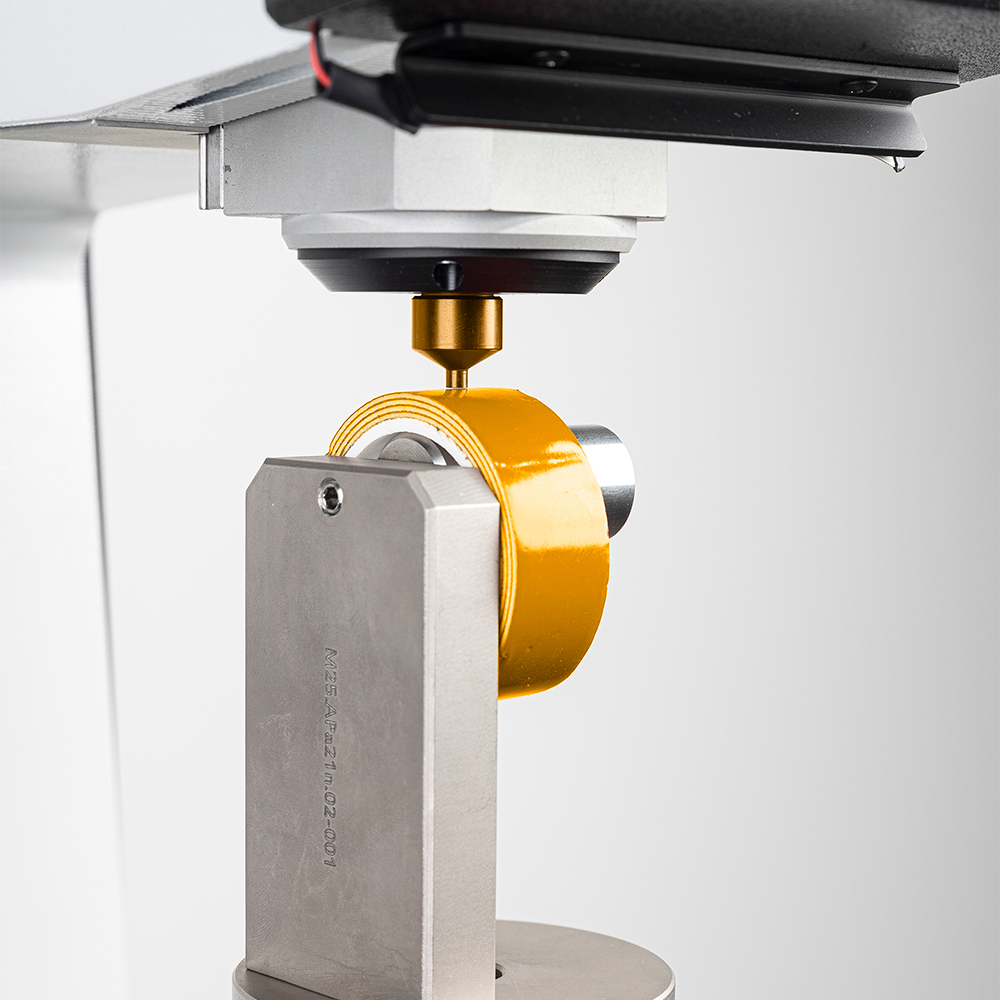

AFFRI WIKI 200

Advanced motorized and automatic with 6 slots turret

Fully automatic and motorized Vickers hardness tester for case depth CHD. Test loads from 0,001 to 100 kgf. It is suitable for CHD (Case Hardness Depth) tests on multiple samples. WIKI 200 JS is conform to ASTM and ISO hardness testing standard.

AFFRI WIKI 90

Automatic with 6 slots turret. Manual X-Y table

Microhardness testing machine WIKI 90 JS is a Vickers and Knoop hardness tester with test loads from 0,001 to 62,5 kgf. This hardness tester is suitable to test Micro Vickers, Macro Vickers, Knoop, and Brinell hardness test scales. WIKI 90 JS is conformed to all hardness standards including ASTM and ISO.

AFFRI WIKI 90 CNC

Automatic micro-hardness tester with multi-position turret

Micro-hardness testing machine WIKI 90 CNC is a Vickers and Knoop hardness tester with test loads from 10gf to 62,5 kgf (at request from 1gf). This hardness tester is suitable to test Micro Vickers, Macro Vickers, Knoop, and Brinell hardness test scales. WIKI 90 CNC is conformed to all hardness standards including ASTM and ISO.

Universal Hardness Testers

ATI HVRB

Fully motorized universal hardness tester

ATI HVRB is an Automatic Universal Hardness Tester for Brinell, Rockwell, and Vickers hardness measurements. ATI HVRB supports test forces ranging from 1kg to 250kg.

AFFRI LD 250 / 750

Fully automatic universal hardness tester

The AFFRI LD250 and LD750 universal hardness testers encompass all standard hardness testing methods, including Rockwell, Superficial Rockwell, Brinell, Brinell HBT, and Vickers. These testers provide accurate hardness measurements for all metals and alloys, fully compliant with ASTM and DIN EN ISO international standards.

AFFRI LD 3000 AX

Semi-automatic universal hardness tester

The system supports Rockwell, Superficial Rockwell, Brinell, Brinell HBT, and Vickers hardness testing methods. It is an automatic hardness testing machine capable of applying test loads ranging from 1 to 3000 kgf. The device ensures precise hardness measurements for all metals and alloys, fully compliant with ASTM, DIN, and EN ISO international standards.

Rubbers and Plastics Hardness Testers

AFFRI MICRODAKO

Fully motorized and automatic universal measurements

AFFRI MICRODAKO is a fully motorized universal hardness tester that determines the hardness of any plastic and rubber material, in accordance with standardized method IRHD and Shore.

- Shore A-B-C-D-D0-0-00-E-M-000-000S

- IRHD L-H-N-M

- High definition of 0.001 IRHD

- ISO 48 / ASTM 1415

AFFRI OKLAOMA

Automated hardness tester in Closed-Loop

AFFRI OKLAOMA is an automated hardness tester for plastics and rubber, featuring advanced software and a closed-loop system to ensure accurate, error-free measurements with minimal external interference. It offers a wide vertical stroke via the elevating screw, and results are displayed automatically with a single command.

- IRHD L-H-N-M

- High definition of 0.001 IRHD

- ISO 48 / ASTM 1415

AFFRI Electronic Shore

Digital portable and bench-top options in a single hardness tester

AFFRI Electronic Shore hardness tester features a slim measuring nose for precise measurements on small components. It is ideal for testing the Shore hardness of various materials, including rubber, plastics, PVC, leather, and more.

AFFRI Shore

Portable hardness tester for rubbers and plastics

The portable AFFRI Shore hardness tester is designed for accurate hardness measurement of rubbers and plastics, covering a wide range of Shore scales (A, B, C, D, E, M, etc.). Compliant with ASTM and ISO standards, it features a slim measuring nose for precise testing on small components and various materials.

Portables Hardness Testers

Portable Magnetic Rockwell hardness tester

ATI MAG is a portable Rockwell hardness tester with a magnetic clamping base. It automatically recognizes the test surface and compensates for any structural deflection, ensuring an accuracy of 0.0001 mm. The tester features an automatic test cycle with a single start input and a load cell system. The magnetic clamping base provides absolute stability throughout the entire test cycle. Hardness results are displayed on the integrated screen.

ATI UCI-918

Automatic portable ultrasonic hardness tester

ATIV AUTO is an automatic Vickers, micro Vickers, and Knoop hardness tester. Just on START button to get start the automated hardness test cycle. ATIV AUTO has a 5-position automatic turret for automatic selection of each tool and it ‘s equipped with motorized X-Y-Z table and auto-focus. Can support multi-indentation cycles and automatic specimen scanning.

Digital portable microscope for automatic reading

The ATI BR is a compact and lightweight portable digital microscope, equipped with intuitive and intelligent software for the automatic reading of Brinell and Vickers indentations. It includes a tablet for viewing readings, analyzing statistics, and exporting data. The ATI BR ensures high reading accuracy even under challenging conditions.

ATI SHORE

Portable digital hardness tester for plastics and rubbers

ATI B3000 is an automatic Brinell hardness tester with one START button to get start the entire automatic Brinell test cycle. ATI B3000 is equipped with a multi-position automatic turret at 5 steps: 3 indenters for Brinell hardness tests and 2 optical lenses (20X and 40X) for indentation reading. The turret rotates 360° horizontally.

AFFRI RSD MAG

Automatic portable hardness tester with magnetic clamping base

AFFRI RSD MAG is a portable Rockwell hardness tester operative up to 360° thanks to its magnetic clamping base that ensures perfect stability during the entire test cycle. The test cycle is automatic, just pull the start lever to perform the measure. Hardness results are displayed on the integrated screen. Accuracy better than 0,0001mm in all test conditions.

AFFRI MK II

Portable hardness tester

AFFRI MK II has unlimited testing positions and safe clamping on any surface, from round to flat samples. Just press the probe to get start the automatic test cycle. Hardness results are displayed on the integrated screen. Completely uninfluenced by direction these testers have the ability to operate up to 360° degrees of positioning, even upside down.

ATI L2

Portable hardness tester with ISO 17025 certificate

ATI L2 is a portable hardness tester and its precise measuring performance delivers accurate results essential for quality control and material verification. A key feature is its ability to automatically identify seven types of impact devices tailored for specific applications, streamlining the testing process.

Universal material testing machines

Universal testing machines

Universal Material Testing Machines are indispensable tools for material characterization, widely used in laboratories and industries across the globe. These versatile systems are capable of performing a wide range of mechanical tests, from tension and compression to bending, cutting, and elongation. Whether for quality control, research, or development, universal testing machines provide precise and reliable data for assessing the mechanical properties of materials.

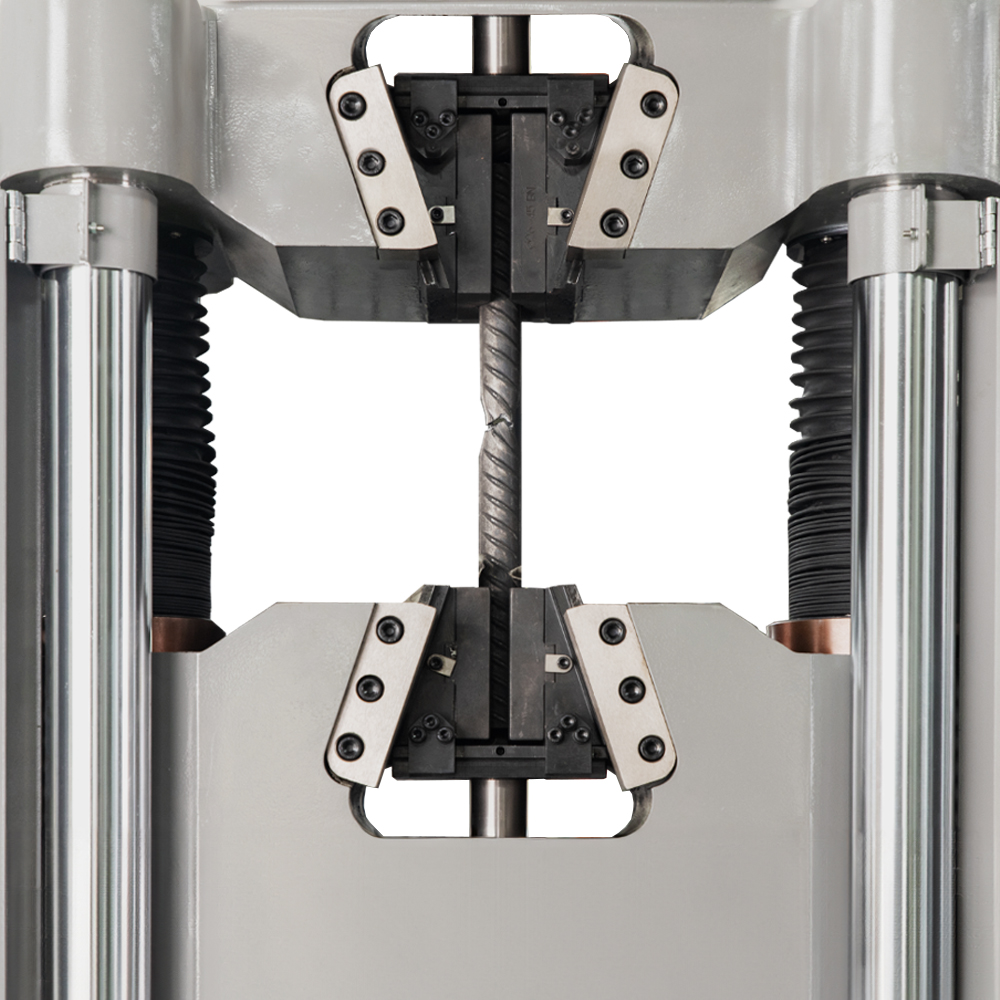

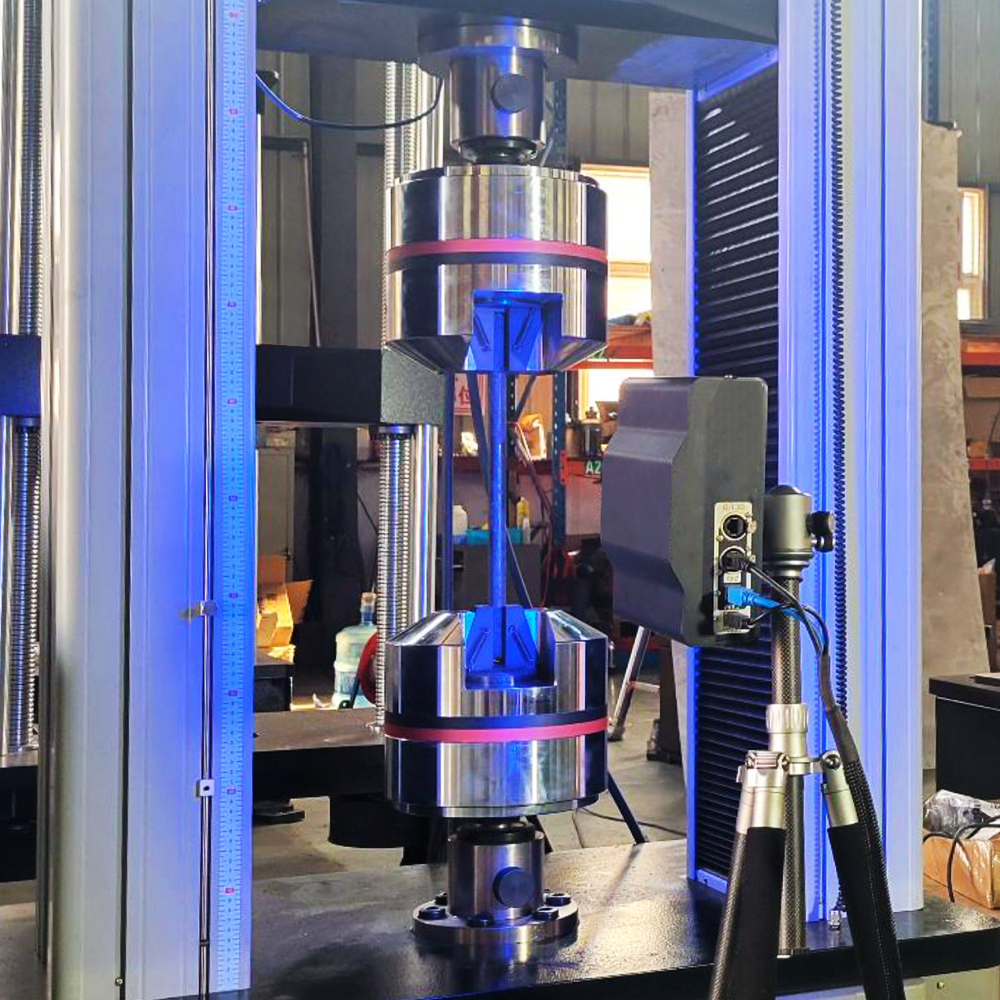

Torsion testers

Universal Torsion testing machines are essential tools for measuring the torque and mechanical properties of materials and components. These versatile instruments are widely used in industries ranging from automotive to manufacturing, helping to assess the durability, strength, and flexibility of various materials under torsional stress. Designed for high accuracy and reliability, torsiometers are key to ensuring product quality and performance.

Spring testers

Universal Springs Testing Machines are essential components in a wide range of industries, including automotive, electronics, and medical sectors. To ensure their functionality and performance, precise testing is crucial. Universal spring testing machines are designed to meet these needs by offering advanced solutions for the characterization and quality control of springs of all types.

Extensometers

Extensometers are essential tools for accurately measuring the deformation and strain of materials under mechanical stress. Widely used in both research and industrial applications, these devices provide precise measurements critical for material testing. Whether for tensile, compression, or other mechanical tests, extensometers enable a deeper understanding of material behavior, allowing for better product design and quality control.

Cutting machines

ATI CUT-380S

Automatic metallographic cutting machine

ATI CUT–380S is an automatic cutting machine designed for precise metallographic sample preparation. ATI CUT-380S includes a double clamping system for secure sample fixation, stainless steel construction to prevent corrosion, and an integrated cleaning system. For visibility, it has transparent plexiglass windows and an LED light.

ATI CUT-350Y

Semi-automatic metallographic cutting machine

ATI CUT–350Y is a semi-automatic metallographic cutting machine designed for safety, precision and efficiency. ATI CUT–350Y offers precise cutting with a sturdy chuck and cutting blade, and the worktable’s movement is controlled either manually or automatically for smooth, stable operation.

ATI CUT-300Z

Manual metallographic cutting machine

ATI CUT–300Z is a manual cutting machine to cut metal samples. The machine adopts closed structure, large observation window, use safe. Its quick clamping mechanism, easy to clamp sample. Have a special cooling water tank, for circulating cooling liquid.

Mounting presses

ATI GLOB-3000

Automatic metallographic mounting press

ATI GLOB–3000 is a fully automatic single station metallurgical mounting press and double or quadruple 3000d multiple stations as optional. Insert up to four samples at once (dual station) or insert two samples (single station).

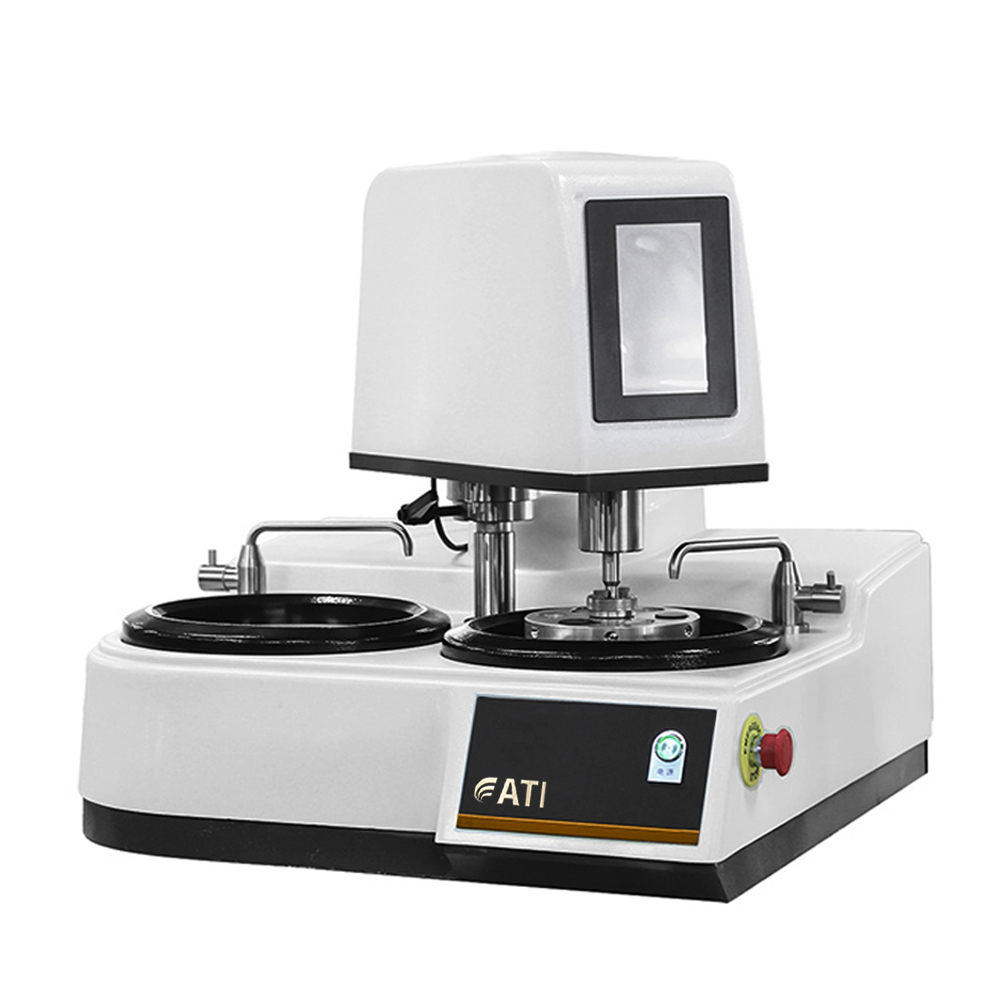

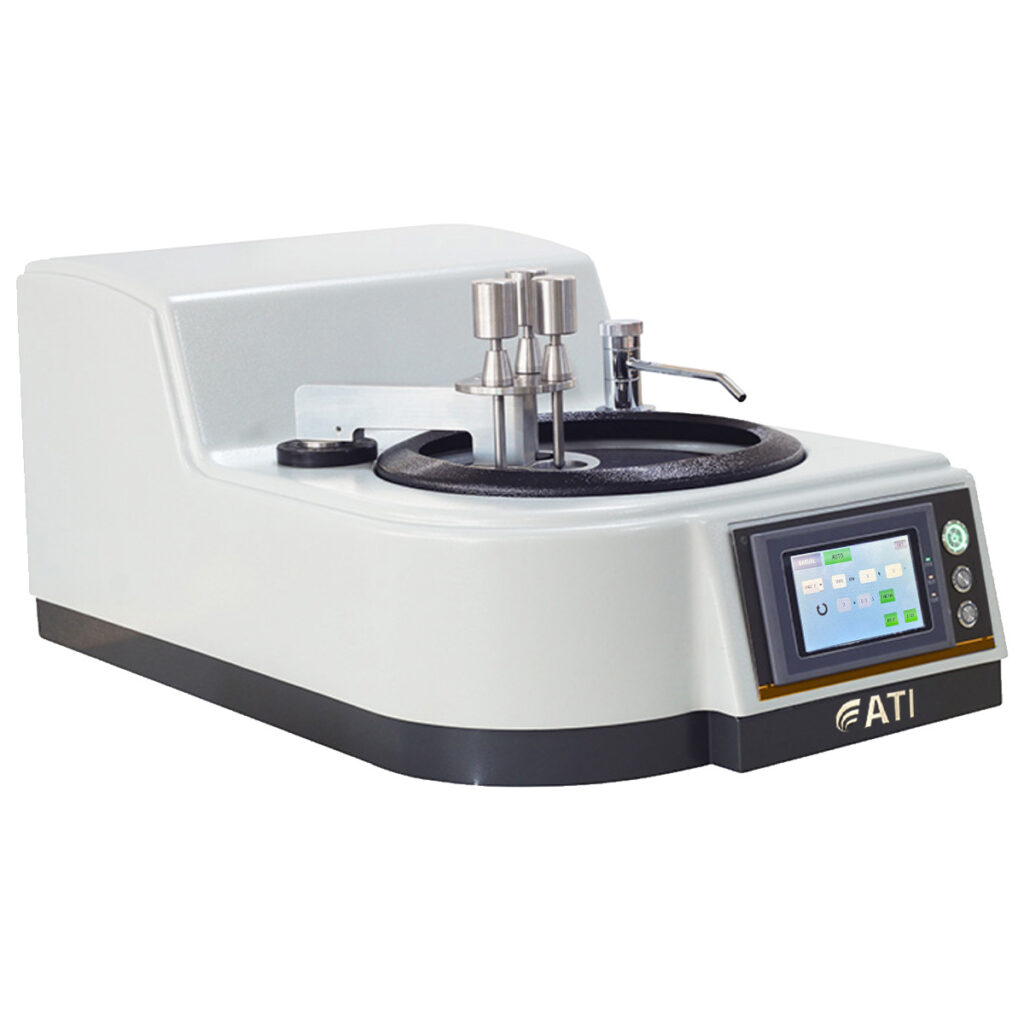

Polishing machines

ATI POL-250

Automatic metallographic polishing machine

ATI POL-250 is automatic metallographic polishing machine for sample preparation. Center loading mode one-time fixed sample can finish grinding and polishing the sample. Loading force can be adjusted during operation flexible and convenient.

ATI POL-254

Semi-automatic metallographic polishing machine

ATI POL–254 is a metallographic polishing machine suitable for polishing 3 samples simultaneously with automatic cycle. Samples rock from side to side for even sanding and polishing

Image Analysis Solutions

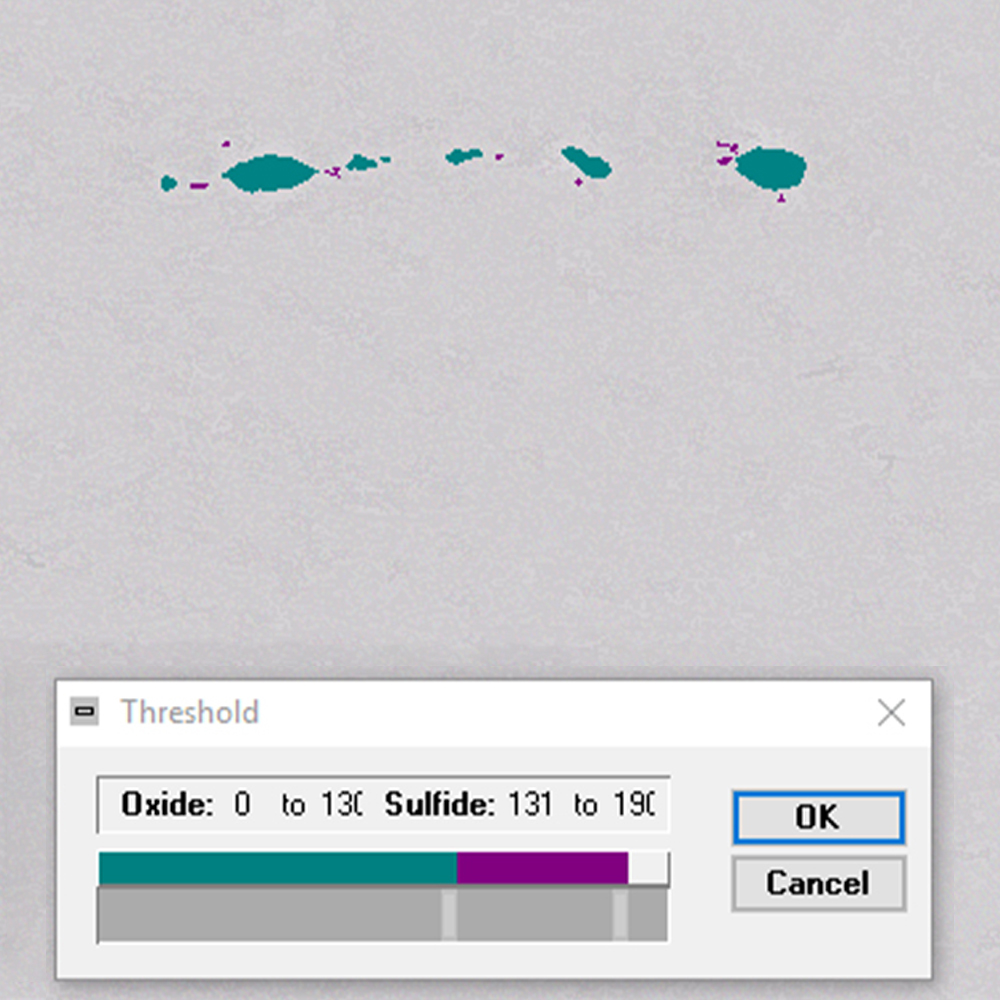

Cleanliness Analysis

The Clemex Vision image analysis system provides a solution for cleanliness analysis within industries where monitoring particle contamination is crucial.

Inclusion Rating V9

This Automated image analysis system is designed to detect the following inclusions and rate them according to most recognized standards: sulfides, aluminates, silicates, globular oxides, single globulars, borides, carbides, nitrides, and carbonitrides.

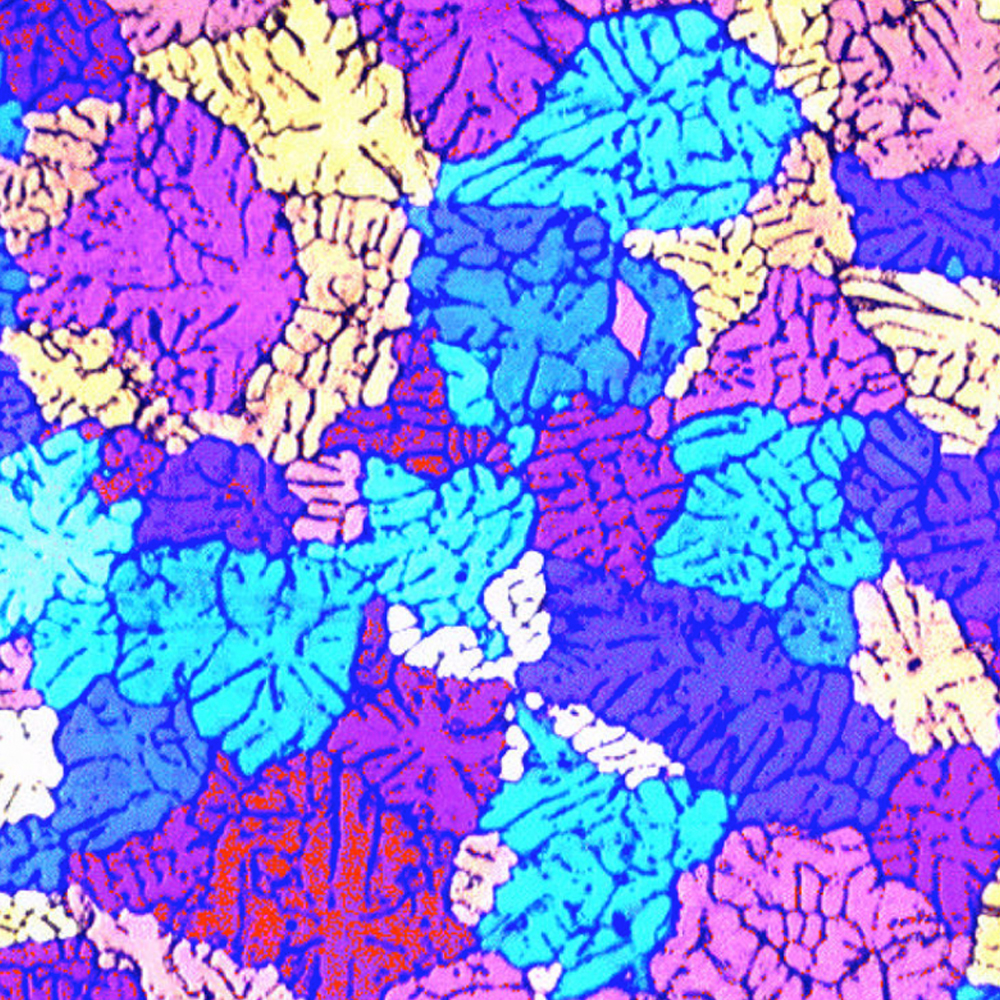

Industrial microscopes

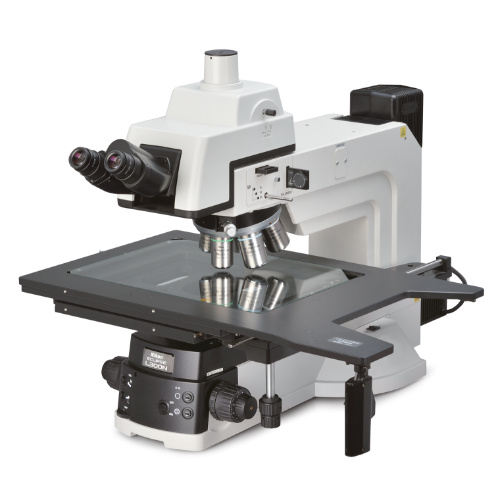

ECLIPSE LV 150NA

Advanced optics deliver high-quality images, supporting multiple contrast techniques. The modular design is ideal for precise material inspection with flexible stage movement and digital imaging options.

ECLIPSE L300ND

High-quality optics and illumination provide excellent contrast and resolution, making these microscopes ideal for semiconductor inspection, including integrated circuits and electronic devices.