AFFRI WIKI 90

Automatic Vickers Micro Hardness Tester

Microhardness testing machine WIKI 90 is a Vickers and Knoop hardness tester with test loads from 0,001 to 62,5 kgf. This hardness tester is suitable to test Micro Vickers, Macro Vickers, Knoop, and Brinell hardness test scales. Wiki 90 JS is conformed to all hardness standards including ASTM and ISO.

- Test loads from 1 gf to 62.5 kgf (0.0098 to 612.9 N)

- Vickers ISO 6507 / ASTM E-384 / ASTM E-92 HV0.001 – HV0.005 – HV0.01 – HV0.015 – HV0.02 – HV0.025 – HV0.05 – HV0.1 – HV0.2 – HV0.3 – HV0.5 – HV1 – HV2 – HV3 – HV5 – HV10 – HV20 – HV30 – HV50

- Knoop ISO 4545 / ASTM E-384 / ASTM E-92 HK0.01 – HK0.02 – HK0.025 – HK0.05 – HK0.1 – HK0.2 – HK0.3 – HK0.5 – HK1

- Brinell ISO 6506 / ASTM E-10 HBW 1/1 – HBW 1/1.25 – HBW 1/2.5 – HBW 1/5 – HBW 1/10 – HBW 1/30 – HBW 2.5/6.25 – HBW 2.5/7.8125 – HBW 2.5/15.625 – HBW 2.5/31.25 – HBW 2.5/62.5

One Touch Measurements

AFFRI WIKI 90 micro-hardness tester is an automated system designed for Vickers, Knoop, or Brinell hardness testing, featuring load cell technology and equipped with a high-definition camera for automatic indentation reading. It includes a motorized turret with six positions and meets ASTM and ISO hardness testing standards.

For microhardness measurement, the process is straightforward: simply place the sample and press the START button. The hardness tester automatically indents the sample, aligns with the camera, measures, and generates data in real-time. Semi-automatic case hardness depth (CHD) tests can be performed easily using the 1µm precision XY table connected to the PC, guided by an assisted procedure.

This tester is suitable for micro-macro Vickers and CHD case depth testing across a wide range of materials, including metals such as iron, steel, tempered steel, cast iron, brass, aluminum, copper, and alloys. It is also used for testing heat-treated, hardened, nitrided, cemented, and hard-faced materials, as well as Knoop testing on ceramics and glass.

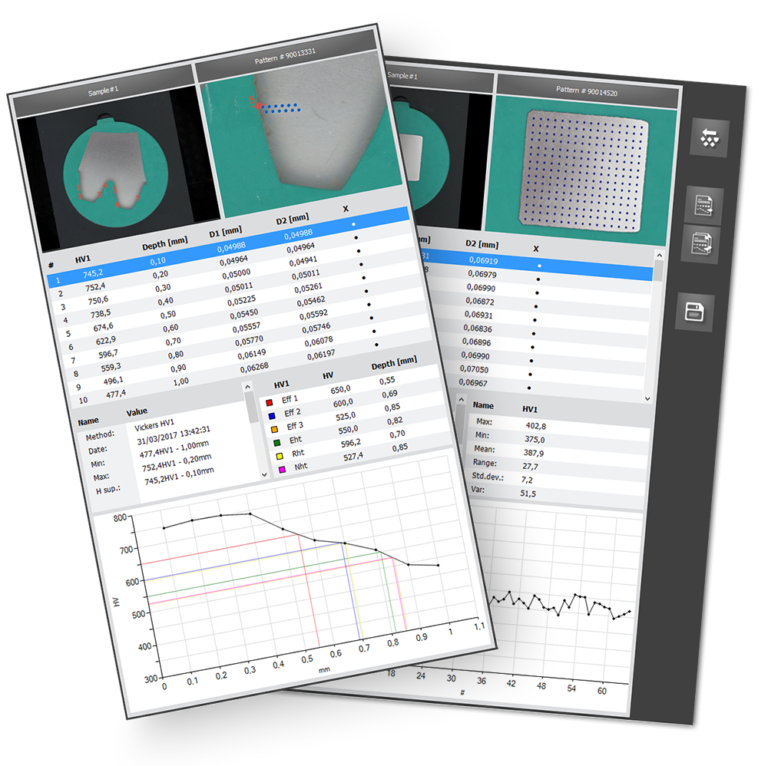

CHD TRAVERSES

- CHD TRAVERSES AND PATTERNS

Single or multiple traverses/patterns can be rapidly created. With one simple click of the line, the angle and the starting point of the indentations are determined. - SEMI-AUTOMATIC CHD TESTS

Digital micrometers connected to the PC. Movements resolution of 1 µm step. Step-by-step assisted procedure to easily test at the perfectly right XY quote. - CREATE, SAVE AND RELOAD

No need to create the same pattern over and over again. This feature is extremely useful for users who analyze the same kind of areas repeatedly. Once a pattern has been created, you can save it and re-load it later to duplicate the analysis on a new sample. - EDIT, MOVE, OR DELETE

Select the pattern from the preview image and modify direction, position, hardness scale, number and distances of indent, pattern name, and point of focus. - IN AND OUT ZOOMING

Zoom out to look at the entire sample in order to identify the pattern position and direction. Zoom-in to verify pattern distances and spot surface imperfections.

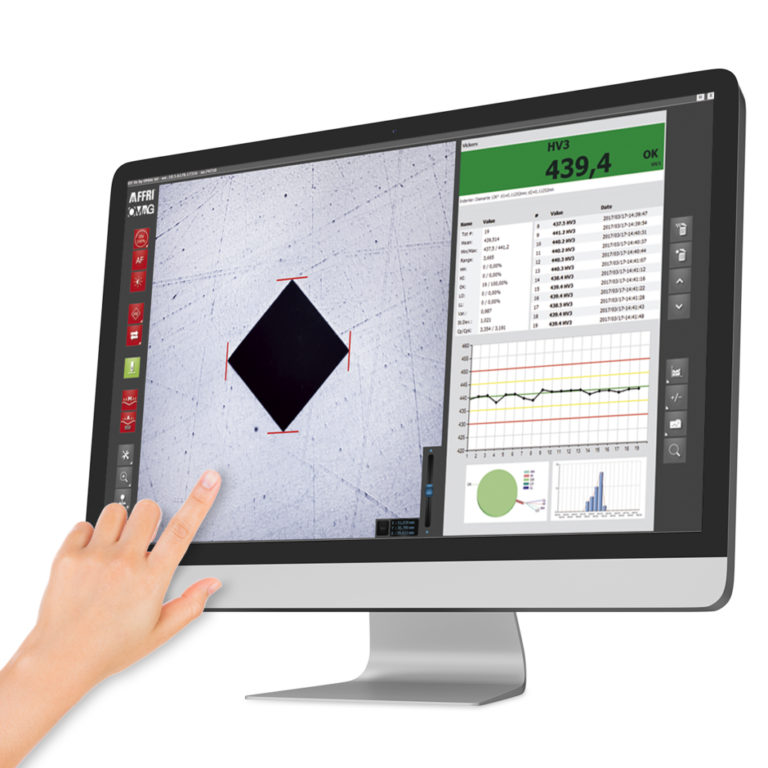

Smart software designed to make your life easier

The Vickers software is designed to meet all measurement requirements, ensuring it is easy for any operator to use. This is a “SMART SOFTWARE”, offering an intuitive interface while being fully equipped with all the necessary functions for both single and multi-cycle Vickers hardness tests.

- Quick and straightforward Vickers testing

- Automatic conversion across all hardness scales (Rockwell, Brinell, Knoop, ASTM, and ISO)

- Multi-sample, multi-test functionality with automatic test cycles

- Automated Vickers case hardness depth (CHD, NHT, EHT, RHT, etc.)

- Measurement of layer dimensions

- Crack analysis

- Automated Vickers testing for welds

- Direct result export via Ethernet

- Fully customizable test reports including client logos, specimen details, indentation images, statistics, and graphs.

Optimize the time

Micro Hardness Tester WIKI 90 CNC is equipped with user-friendly software that is designed to be intuitive and easy to operate. For case hardness depth testing, the process is streamlined into three simple steps, making it quick and efficient. The software provides clear guidance, ensuring that users of all experience levels can perform accurate tests with minimal effort. This simplicity allows for faster turnaround times and increased productivity, while still maintaining.

- Obtain a perfect, detailed, high-resolution panoramic view of the sample using the panoramic feature. The picture is clear, sharp, and without any distortion.

- Create, save, open, modify, copy or paste Vickers multi-tests to predefined locations with a simple click. Create case depth traverses or fill a surface with indentation points to control sample uniformity.

- The hardness tester brings you to the right position, indents the sample, measures, and generates data dynamically. Review results in graphical and/or tabular format. Export results to any spreadsheet application, or simply print standard or customized reports.

The Vickers hardness tester teaches the operator how to move, saving time and money, thus increasing the accuracy of results.

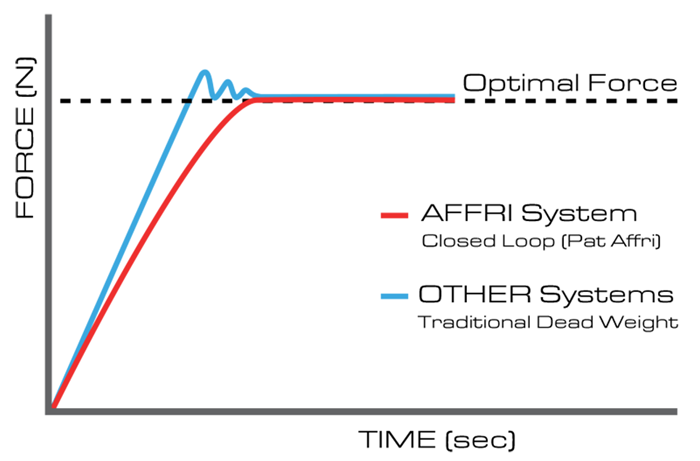

Auto-compensation of all deflections

When testing unstable or deflecting specimens, the AFFRI System ensures continuous contact by following the sample, thanks to its unlimited stroke for both the indenter and clamping hood. The load forces are applied through load cells and managed within a “Closed Loop” system, operating at a frequency of 1 kHz, guaranteeing flawless linearity across all ranges. This ensures that results remain unaffected by any structural distortions, misalignments, or vibrations. Precise measurements are achieved on the first attempt, even under challenging conditions, which eliminates the need for multiple tests. The repeatability and reproducibility (R&R) data consistently ranks among the best in its category.

MAIN FEATURES

MOTORIZED TURRET

A horizontally rotating turret equipped with four slots for magnification lenses and two dedicated to indenters. Pre-installed optical microscope objectives can be paired with indenters to accommodate all Vickers and Knoop hardness scales.

MAIN FEATURES

DIGITAL XY STAGE

Dimensions: 135x135mm, with a travel range of 50x50mm and a digital resolution of 0.001mm per step. Featuring micrometers linked to a PC and software for multi-indentation patterns, this table is an ideal choice for semi-automatic CHD case hardness depth evaluations.

MAIN FEATURES

PRECISE FOCUSING

The conveniently positioned ergonomic wheel on the side of the tester manages the Z-axis across the full vertical stroke. It enables fine-tuned focus adjustments for small indentations and facilitates swift, extensive movements to accommodate samples with ease.

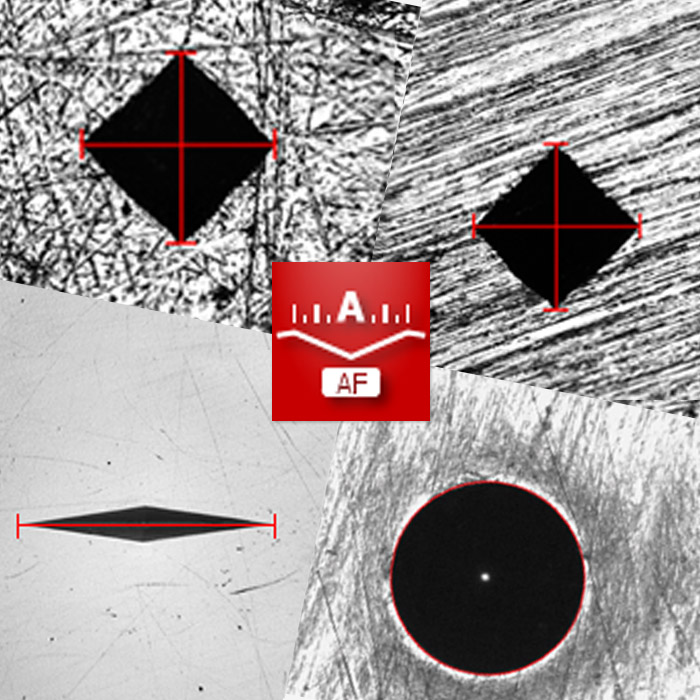

AUTOMATIC READING

Horizontally rotating turret featuring four slots for magnification lenses and two designated for indenters. All optical microscope objectives can be pre-configured and paired with indenters suitable for any Vickers and Knoop hardness scale.

LIGHT CONTROL

Automatic lighting adjustment ensures optimal visibility on dark, opaque, or polished surfaces. The hardness tester automatically regulates light intensity and contrast to achieve the ideal settings for indent measurement. Simply position the sample and press the illumination button to observe the adjustments.

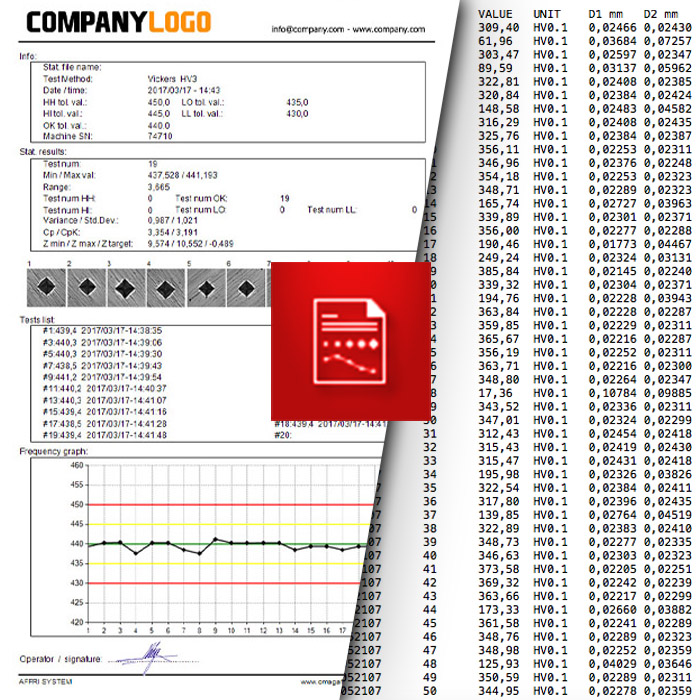

TEST REPORT

Create fully customizable test reports that include your company logo and detailed information. Add as much sample data as required, including images of the indents and the test area. Analyze results, review statistics, and view the CHD diagram. Export results seamlessly in CSV format for further processing.