EASYDUR INTEGRAL 1

Brinell Hardness Tester with Fully Motorized and Automatic Test Cycle

EASYDUR INTEGRAL 1 is a Brinell hardness tester with fully motorized and automatic test cycle, not affected by operator influences. Vertical capacity 500 mm /20″ and horizontal capacity 170 mm /6.5″. Milling station is built-in for sample preparation.

- Test loads from 1 to 3000 kgf (from 9,807 to 29421 N) – As optional from 0,1 kgf (0,9807 N)

- Brinell HBW ISO 6506 / ASTM E-10 HBW 1/30 – HBW 2.5/15.625 – HBW 2.5/31.25 – HBW 2.5/62.5 – HBW 2.5/187.5 – HBW 5/25 – HBW 5/31.25 – HBW 5/62.5 – HBW 5/125 – HBW 5/250 – HBW 5/750 – HBW 10/100 – HBW 10/125 – HBW 10/250 – HBW 10/500 – HBW 10/1000 – HBW 10/1500 – HBW 10/3000 Optional: HBW 1/1 – HBW 1/1.25 – HBW 1/2.5 – HBW 1/5 – HBW 2.5/6.25 – HBW 2.5/7.8125

FULLY AUTOMATED SYSTEM

This advanced hardness tester provides seamless operation with automatic sample contact, precise loading, and optical indentation measurement through an integrated camera system. The Integral 1 is equipped with the sophisticated EASYDUR System, ensuring exceptional load accuracy and measurement resolution for Brinell hardness testing.

ONE-TOUCH MEASUREMENTS

The hardness measurement process is incredibly straightforward, fast, and reliable. The entire testing cycle is fully automated, requiring only a single command (via button or on-screen icon):

- Automatic contact with the sample

- Self-adjusting clamping mechanism for secure specimen positioning

- Automatic load application

- Optical lens activation for precise measurements

- Autofocus via image brightness scanning

- Automatic measurement and result display

- Automatic return stroke, retracting to a pre-set distance

This system significantly enhances testing efficiency, accuracy, and user-friendliness, making it ideal for both industrial and laboratory applications.

AUTOMATIC CONTACT WITH THE SPECIMENS FROM ANY DISTANCE

Fully motorized, adjustable testing stand offers a vertical capacity of up to 500 mm (20”), with the option to extend to 700 mm (28”). This system includes automatic contact with the test surface, regardless of the distance, and is activated with a single start command. The test cycle begins automatically as soon as the head makes contact with the specimen, which is instantly detected and recognized at any point within the vertical range. This functionality ensures precise, effortless testing at various heights, making it ideal for a wide range of applications. The stand’s motorized adjustments allow for smooth and precise positioning, enhancing the overall efficiency and accuracy of the testing process.

- Vertical capacity from base to the indenter 500mm / 20″ (more on request)

- Horizontal capacity from column to the indenter 170 mm / 6.5” (more on request)

The Integral hardness tester is a durable system designed for use in tough environments, capable of handling large, heavy samples with a forklift or crane.

AUTO-COMPENSATION OF ALL DEFLECTIONS

During the testing of unstable specimens or deflecting components, the System ensures continuous contact with the sample, regardless of movement, thanks to its infinite stroke for both the indenter and the clamping hood.

The application of load forces is achieved through precision load cells, with control managed in a “Closed Loop” configuration at a frequency of 1 kHz. This guarantees perfect linearity across all measurement ranges, ensuring that results remain unaffected by structural deflections, misalignments, or external vibrations. Measurements are precise from the first test, even in challenging or extreme conditions, thereby eliminating the need for repeated tests. The system provides exceptional R&R (Repeatability and Reproducibility) performance, establishing it as a leader in testing accuracy and reliability. This advanced capability ensures outstanding consistency, making it ideal for high-demand applications in both industrial and laboratory environments.

THE EXCLUSIVE MILLING TOOL

EASYDUR Integral 1 universal hardness tester can be fitted with a sample preparation system that is directly mounted on the instrument’s head.

- Save time! Only 30 seconds to get the Brinell result!

- Increase the accuracy and the quality of your Brinell results

- Automatize the quality inspection process

- Move human resources to other jobs

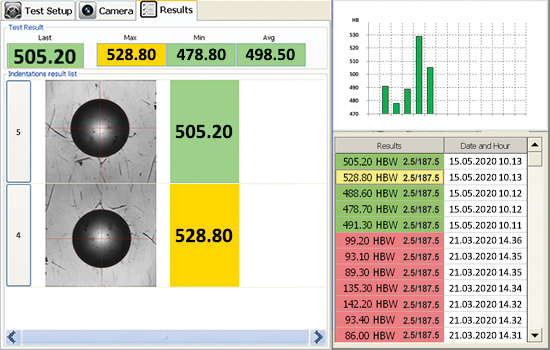

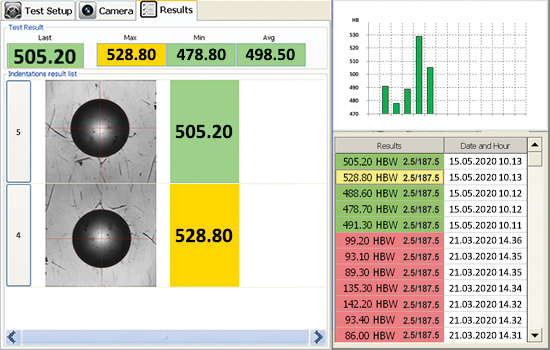

SOFTWARE

EASYDUR Integral 1 universal hardness tester comes with pre-installed software that manages the entire testing process, minimizing the risk of operator errors.

- 15″ Touchscreen

- Intuitive, user-friendly interface

- Color-coded result indicators (low/ok/high)

- Real-time statistics and graphical displays

- Customizable test settings programs

- Result archiving

- Image capture and storage

- Export results in various formats including PDF, TXT, CSV, DOC, XLS, and more

- Barcode scanning for data input

- Output options via RS232, USB, and Ethernet

- Seamless data exchange with MES management systems.

MAIN FEATURES

MOTORIZED TURRET

The turret can accommodate up to 8 slots (or more) for various hardness scale indenters, optical lenses, lasers, and even a milling tool for surface preparation. It features auto-rotation and auto-tool switching, enabling a fully automated measurement cycle. This setup allows for both single and multi-method hardness testing using a single instrument.

MAIN FEATURES

CLAMPING SYSTEM

A secure connection with the specimen is consistently maintained, even in the rare case of any movement during the test cycle. The clamping system guarantees full stability of the test piece throughout the entire process, regardless of its whether condition oiled, rusty, or contaminated with dirt.

MAIN FEATURES

HARD BASE

The spacious worktable base is designed to support weights exceeding 3000 kg, along with specialized fixtures or anvils. It allows for hardness testing of large and irregularly shaped specimens that are difficult to accommodate with standard bench hardness testers.

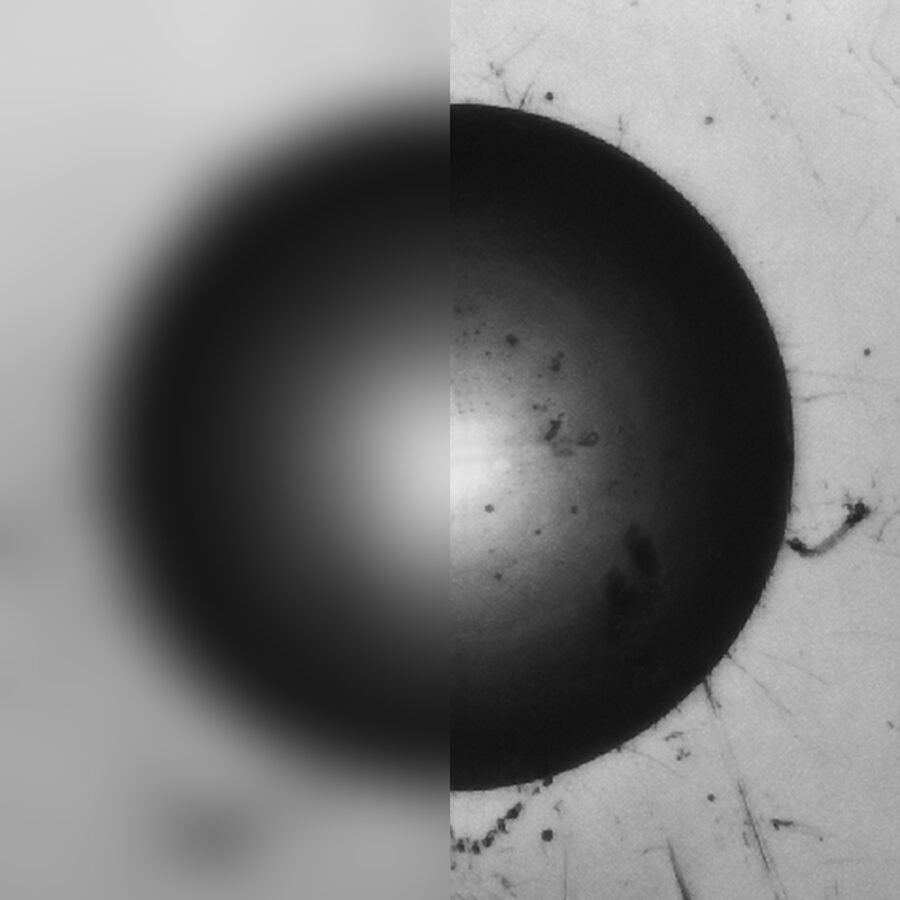

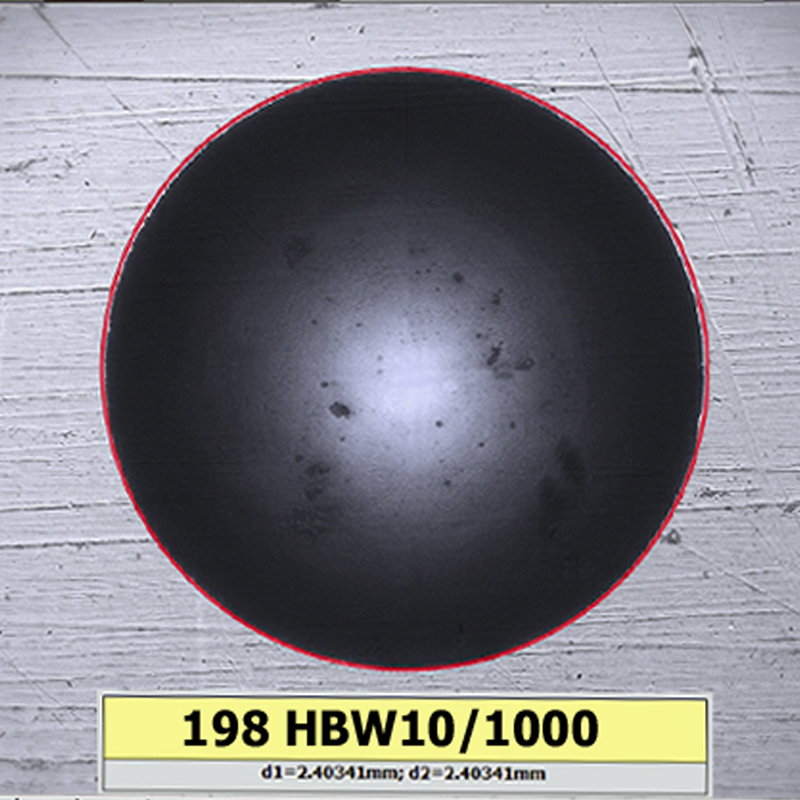

AUTOFOCUS

The automatic focus adjustment system for each optic ensures precise positioning at any magnification, utilizing real image brightness scanning with continuous steps for infinite accuracy. This technology guarantees high reading standards, reproducible focus values, and reduces reading time. Hardness measurements remain objective, unaffected by subjectivity.

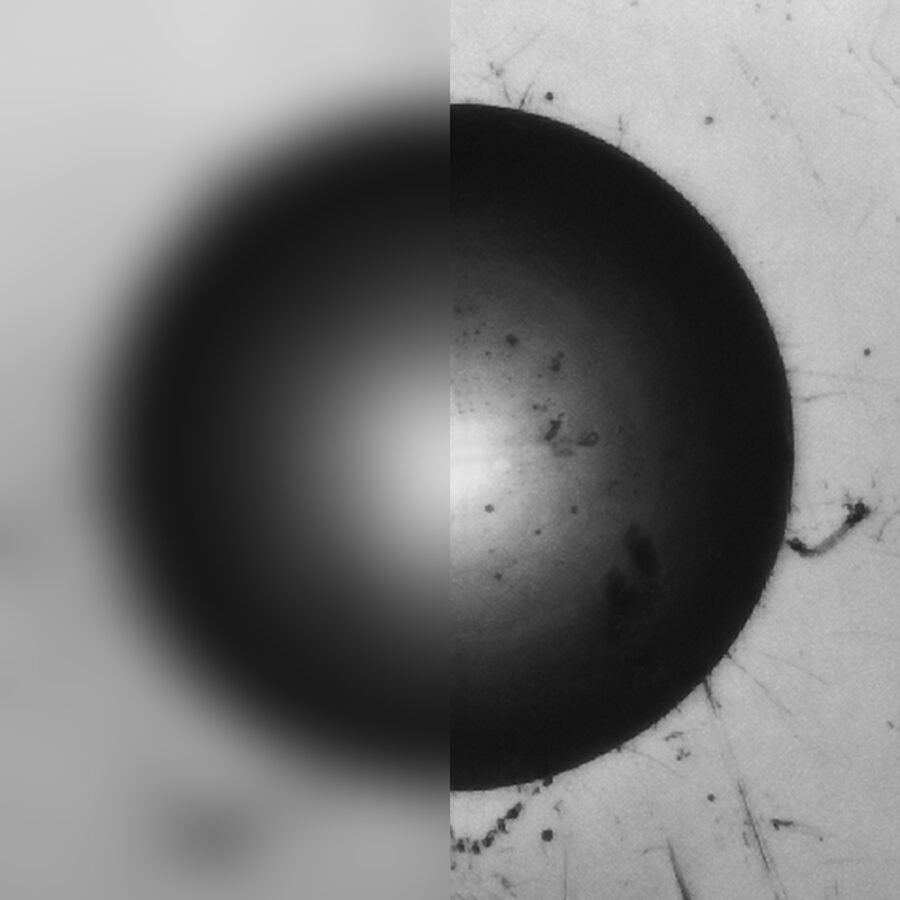

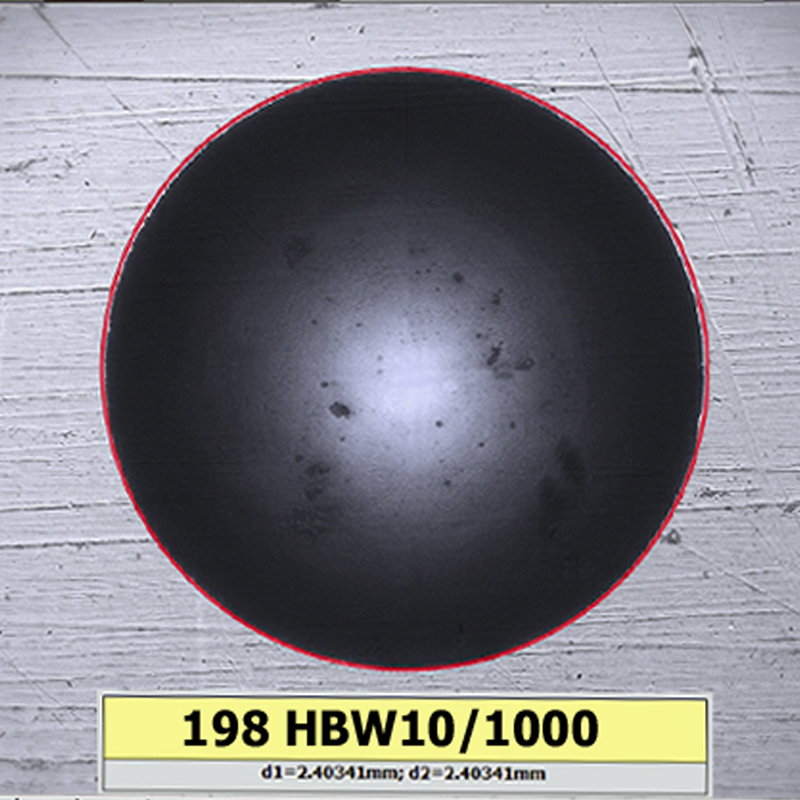

CAMERA AUTO-READING

The software automatically measures indentations on any sample surface, ranging from perfectly polished to rough or etched materials. It features automatic light regulation for dark, opaque, or polished samples, adjusting both light and contrast to optimize visibility and ensure accurate indentation measurements.

MOTORIZED X-Y TABLE

With a division accuracy of 0.5µ/step and able to support 3000kgf of testing load, the XY table is used for automatic multi-indentation measurement. The user can program and set the number of indentations to be performed and the related movement of the X/Y table before each indent. Customizable dimension size.

EASYDUR INTEGRAL 1

Brinell Hardness Tester with Fully Motorized and Automatic Test Cycle

EASYDUR INTEGRAL 1 is a Brinell hardness tester with fully motorized and automatic test cycle, not affected by operator influences. Vertical capacity 500 mm /20″ and horizontal capacity 170 mm /6.5″. Milling station is built-in for sample preparation.

- Test loads from 1 to 3000 kgf (from 9,807 to 29421 N) – As optional from 0,1 kgf (0,9807 N)

- Brinell HBW ISO 6506 / ASTM E-10 HBW 1/30 – HBW 2.5/15.625 – HBW 2.5/31.25 – HBW 2.5/62.5 – HBW 2.5/187.5 – HBW 5/25 – HBW 5/31.25 – HBW 5/62.5 – HBW 5/125 – HBW 5/250 – HBW 5/750 – HBW 10/100 – HBW 10/125 – HBW 10/250 – HBW 10/500 – HBW 10/1000 – HBW 10/1500 – HBW 10/3000 Optional: HBW 1/1 – HBW 1/1.25 – HBW 1/2.5 – HBW 1/5 – HBW 2.5/6.25 – HBW 2.5/7.8125

FULLY AUTOMATED SYSTEM

This advanced hardness tester provides seamless operation with automatic sample contact, precise loading, and optical indentation measurement through an integrated camera system. The Integral 1 is equipped with the sophisticated EASYDUR System, ensuring exceptional load accuracy and measurement resolution for Brinell hardness testing.

ONE-TOUCH MEASUREMENTS

The hardness measurement process is incredibly straightforward, fast, and reliable. The entire testing cycle is fully automated, requiring only a single command (via button or on-screen icon):

- Automatic contact with the sample

- Self-adjusting clamping mechanism for secure specimen positioning

- Automatic load application

- Optical lens activation for precise measurements

- Autofocus via image brightness scanning

- Automatic measurement and result display

- Automatic return stroke, retracting to a pre-set distance

This system significantly enhances testing efficiency, accuracy, and user-friendliness, making it ideal for both industrial and laboratory applications.

AUTOMATIC CONTACT WITH THE SPECIMENS FROM ANY DISTANCE

Fully motorized, adjustable testing stand offers a vertical capacity of up to 500 mm (20”), with the option to extend to 700 mm (28”). This system includes automatic contact with the test surface, regardless of the distance, and is activated with a single start command. The test cycle begins automatically as soon as the head makes contact with the specimen, which is instantly detected and recognized at any point within the vertical range. This functionality ensures precise, effortless testing at various heights, making it ideal for a wide range of applications. The stand’s motorized adjustments allow for smooth and precise positioning, enhancing the overall efficiency and accuracy of the testing process.

- Vertical capacity from base to the indenter 500mm / 20″ (more on request)

- Horizontal capacity from column to the indenter 170 mm / 6.5” (more on request)

The Integral hardness tester is a durable system designed for use in tough environments, capable of handling large, heavy samples with a forklift or crane.

AUTO-COMPENSATION OF ALL DEFLECTIONS

During the testing of unstable specimens or deflecting components, the System ensures continuous contact with the sample, regardless of movement, thanks to its infinite stroke for both the indenter and the clamping hood.

The application of load forces is achieved through precision load cells, with control managed in a “Closed Loop” configuration at a frequency of 1 kHz. This guarantees perfect linearity across all measurement ranges, ensuring that results remain unaffected by structural deflections, misalignments, or external vibrations. Measurements are precise from the first test, even in challenging or extreme conditions, thereby eliminating the need for repeated tests. The system provides exceptional R&R (Repeatability and Reproducibility) performance, establishing it as a leader in testing accuracy and reliability. This advanced capability ensures outstanding consistency, making it ideal for high-demand applications in both industrial and laboratory environments.

THE EXCLUSIVE MILLING TOOL

EASYDUR Integral 1 universal hardness tester can be fitted with a sample preparation system that is directly mounted on the instrument’s head.

- Save time! Only 30 seconds to get the Brinell result!

- Increase the accuracy and the quality of your Brinell results

- Automatize the quality inspection process

- Move human resources to other jobs

SOFTWARE

EASYDUR Integral 1 universal hardness tester comes with pre-installed software that manages the entire testing process, minimizing the risk of operator errors.

- 15″ Touchscreen

- Intuitive, user-friendly interface

- Color-coded result indicators (low/ok/high)

- Real-time statistics and graphical displays

- Customizable test settings programs

- Result archiving

- Image capture and storage

- Export results in various formats including PDF, TXT, CSV, DOC, XLS, and more

- Barcode scanning for data input

- Output options via RS232, USB, and Ethernet

- Seamless data exchange with MES management systems.

MOTORIZED TURRET

The turret can accommodate up to 8 slots (or more) for various hardness scale indenters, optical lenses, lasers, and even a milling tool for surface preparation. It features auto-rotation and auto-tool switching, enabling a fully automated measurement cycle. This setup allows for both single and multi-method hardness testing using a single instrument.

CLAMPING SYSTEM

A secure connection with the specimen is consistently maintained, even in the rare case of any movement during the test cycle. The clamping system guarantees full stability of the test piece throughout the entire process, regardless of its whether condition oiled, rusty, or contaminated with dirt.

HARD BASE

The spacious worktable base is designed to support weights exceeding 3000 kg, along with specialized fixtures or anvils. It allows for hardness testing of large and irregularly shaped specimens that are difficult to accommodate with standard bench hardness testers.

AUTOFOCUS

The automatic focus adjustment system for each optic ensures precise positioning at any magnification, utilizing real image brightness scanning with continuous steps for infinite accuracy. This technology guarantees high reading standards, reproducible focus values, and reduces reading time. Hardness measurements remain objective, unaffected by subjectivity.

CAMERA AUTO-READING

The software automatically measures indentations on any sample surface, ranging from perfectly polished to rough or etched materials. It features automatic light regulation for dark, opaque, or polished samples, adjusting both light and contrast to optimize visibility and ensure accurate indentation measurements.

MOTORIZED X-Y TABLE

With a division accuracy of 0.5µ/step and able to support 3000kgf of testing load, the XY table is used for automatic multi-indentation measurement. The user can program and set the number of indentations to be performed and the related movement of the X/Y table before each indent. Customizable dimension size.