THE MOST ADVANCED IMAGE ANALYSIS SOLUTION

Clemex Vision is a fully integrated system for labs seeking traceable, repeatable, and accurate results. This is our most powerful automated image analysis system. It includes a great range of computer vision functions, catering for various applications in industry and research. Our image analysis software is exceptionally flexible, allowing for any number of distinct routines to be run on the same system. These routines come packaged as a library of existing applications or can be developed by our application specialists.

APPLICATION PACKAGES

STANDARDS

- ASME B46.1 Surface Texture (Surface Roughness, Waviness, and Lay)

- ASTM A247 Microstructure of Graphite in Iron Castings

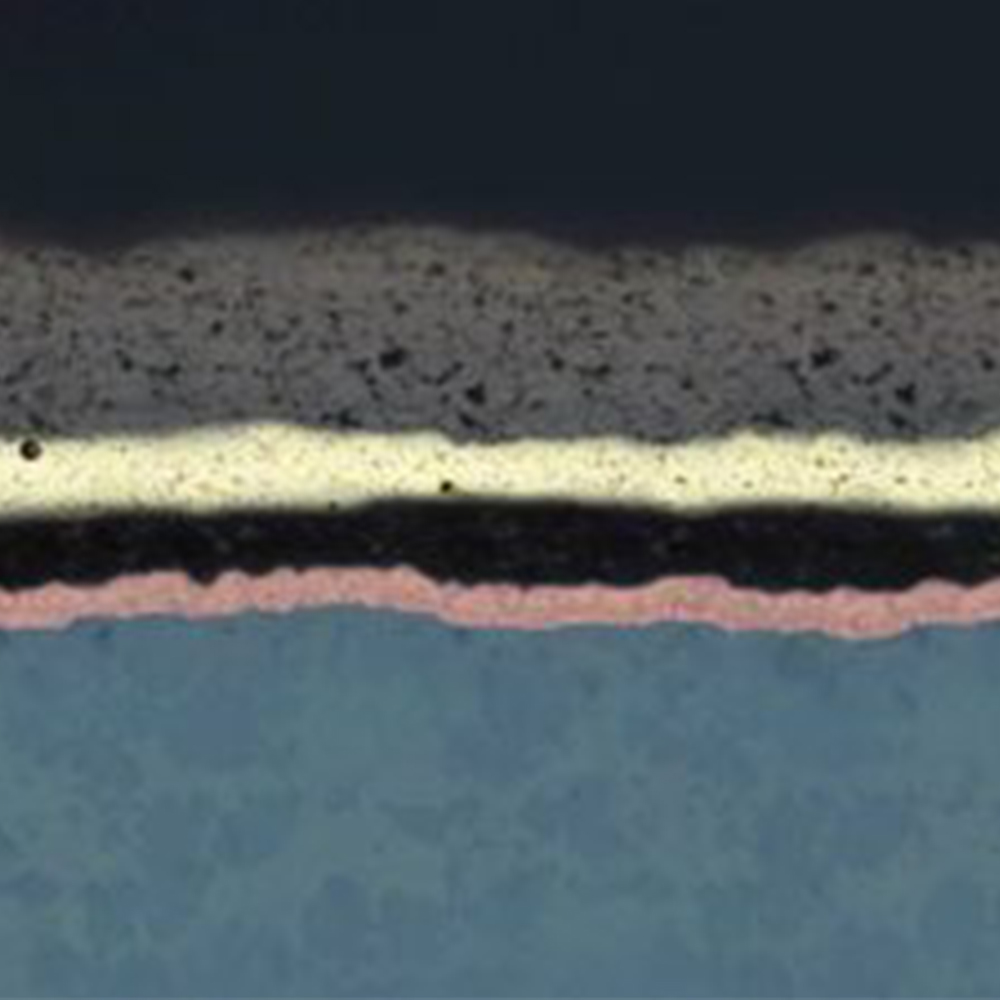

- ASTM B487 Measurement of Metal and Oxide Coating Thickness

- ASTM E1077 Depth of Decarburization of Steel Specimens

- ASTM E112 Average Grain Size

- ASTM E1245 Inclusion or Second-Phase Constituent Content of Metals

- ASTM E1268 Degree of Banding or Orientation of Microstructures

- ASTM E562 Volume Fraction by Systematic Manual Point Count

- DIN 17230 Ball and Roller Bearing Steels

- ISO 945 Microstructure of Cast Irons

ANALYSIS TYPES

- Bending

- Cell size

- Custom measurements

- Decarburization

- Dendritic arm spacing

- Density

- Flake size

- Gamma prime

- Grain size

- Layer thickness

- Morphology

- Nodularity

- Object orientation

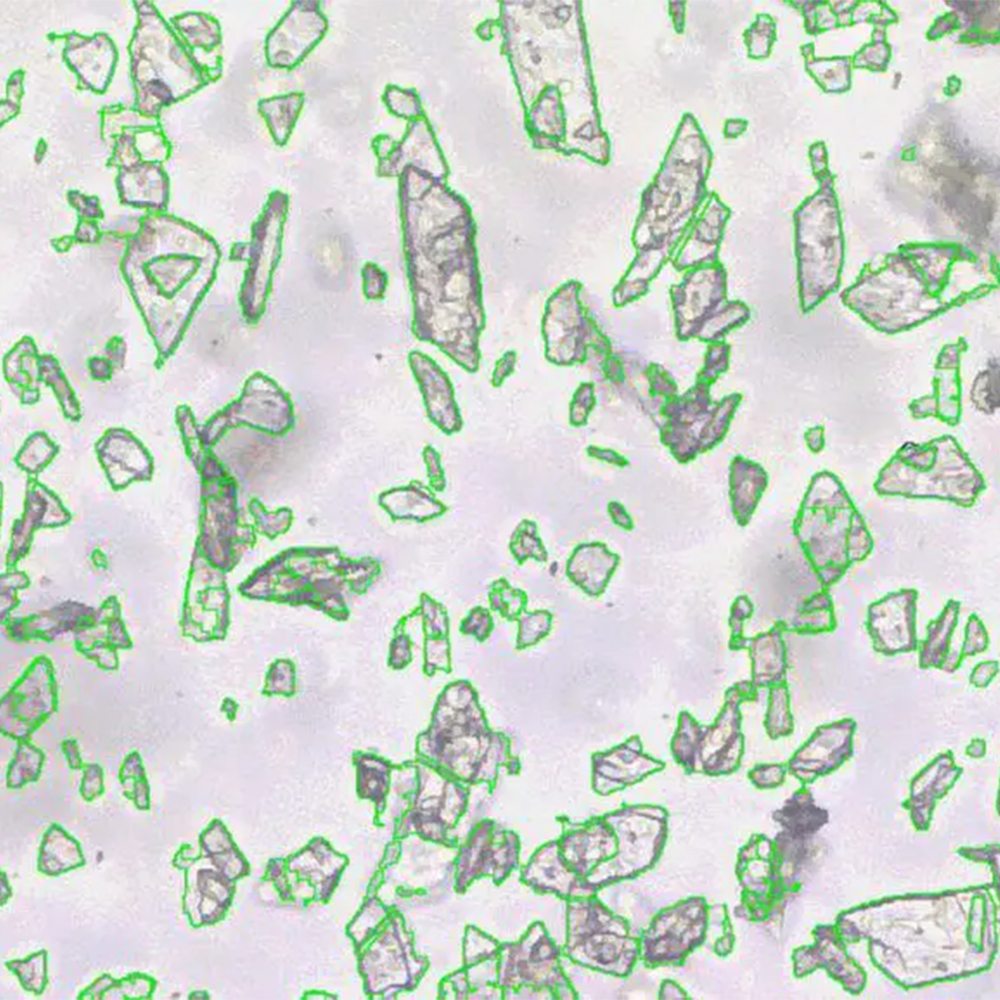

- Particle size and shape

- Phase analysis

- Porosity

KEY FEATURES OF CLEMEX VISION ANALYSIS SOFTWARE

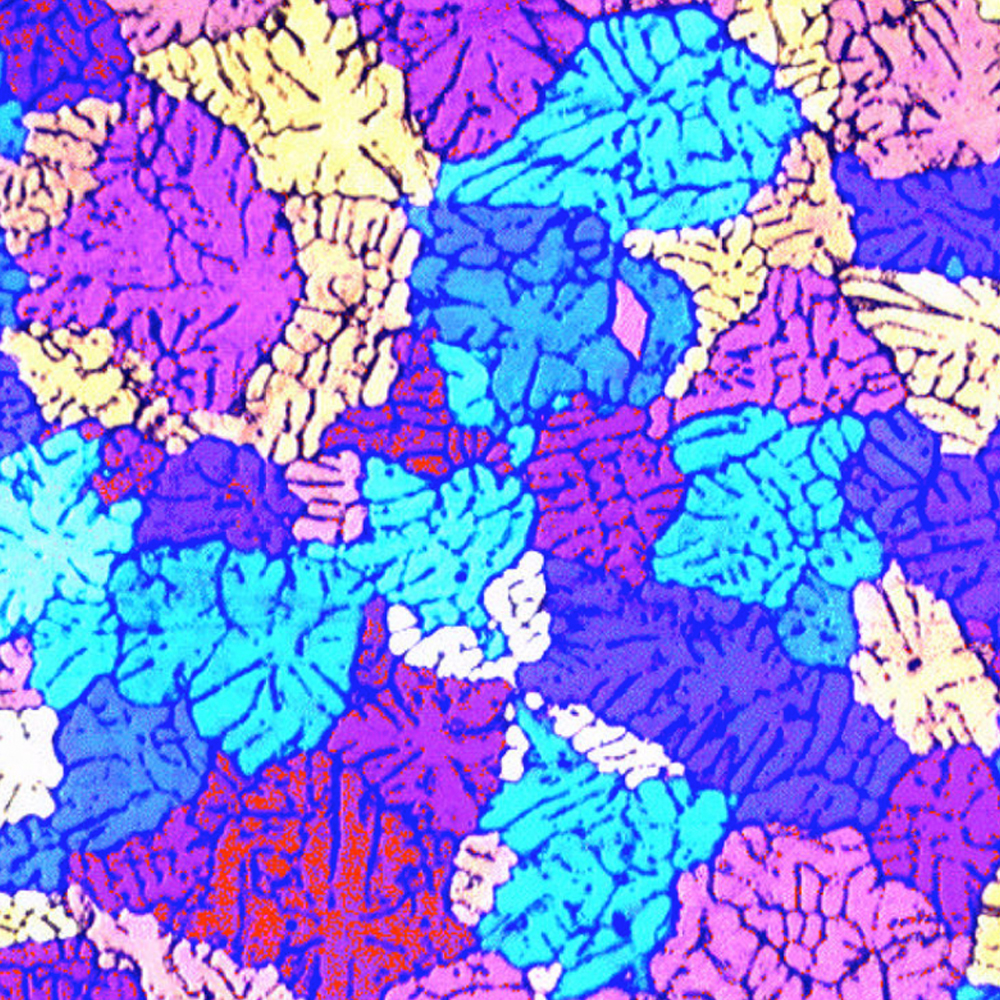

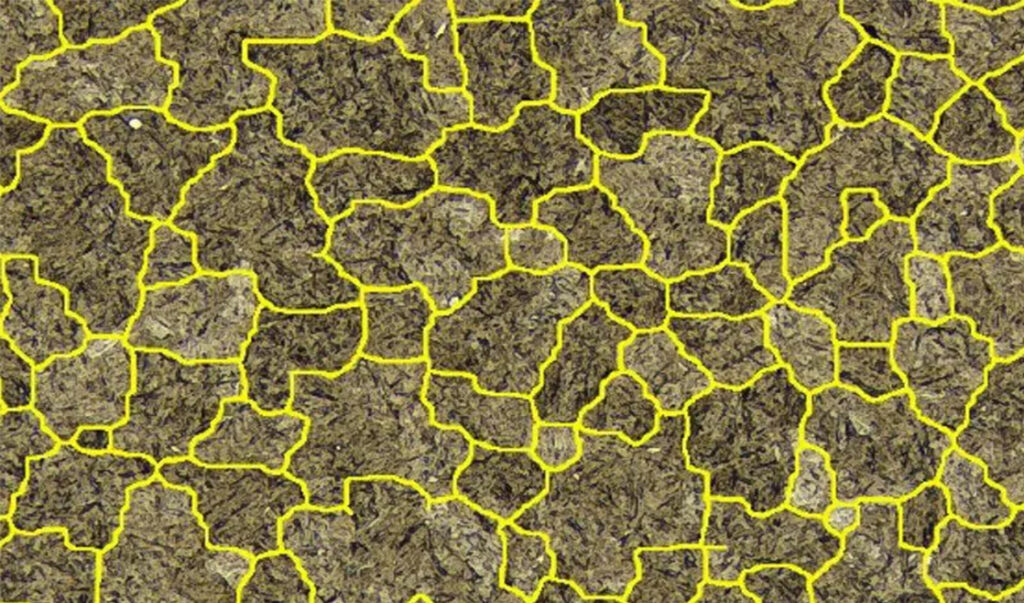

UNIVERSAL GRAIN SIZE ANALYSIS

With the AI Plugin “GrainSeg”, segmenting even the most difficult images is fast and reliable. You can analyze copper alloys, austenitic steels or titanium alloys containing twins and it supports all methods of the ASTM-E112 standard.

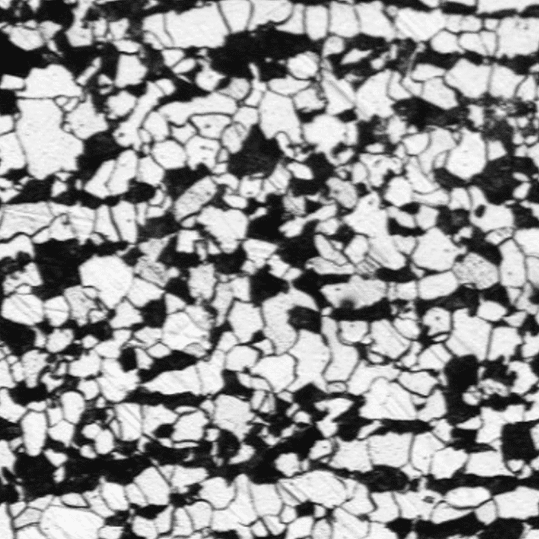

MARTENSITIC GRAIN SIZE INSTRUCTION

The powerful Martensitic functionality is inserted at the beginning of an automated image analysis routine to detect the boundaries of grains. Several parameters allow the user to fine-tune detection.

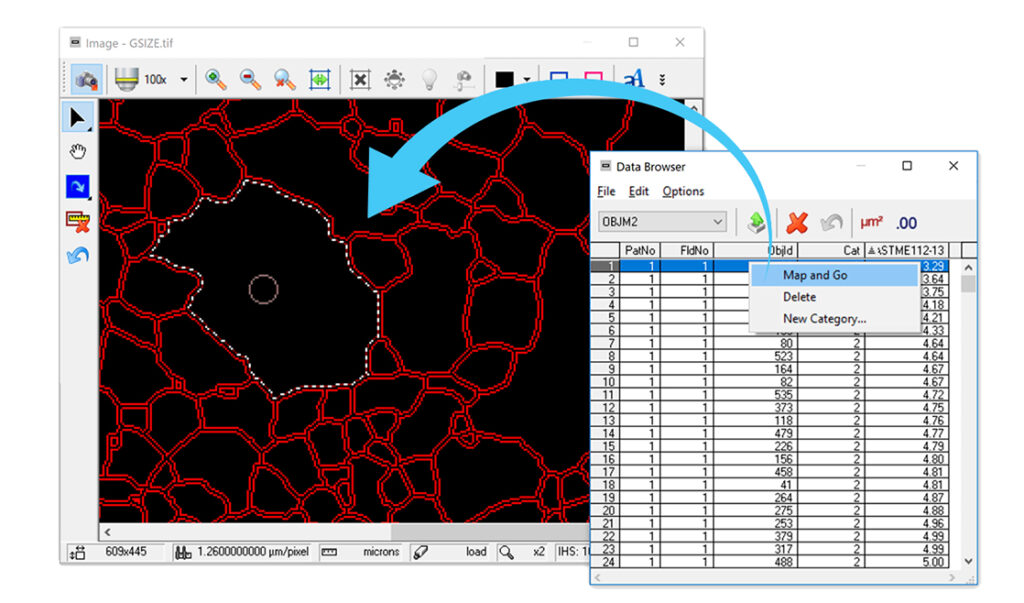

TRACEABLE DATA

Validate detected features and delete artifacts across multiple fields using the Map and Go function. Object data in the built-in spreadsheet are dynamically linked to the actual position of the objects on the sample.

ANALYSIS PROPERTIES

Information from property fields can be automatically inserted into reports, file names or folder names. Use standard properties such as Magnification, Date or Sample Name or create custom fields.

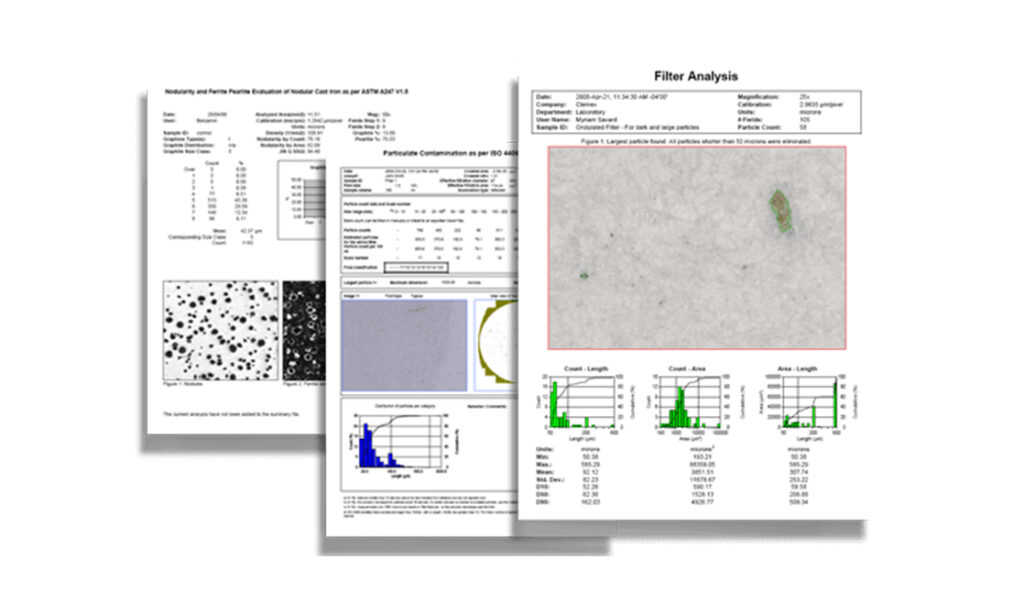

AUTOMATED REPORTING

Reports are generated automatically after each analysis and can be adapted to suit your needs. Add a company logo, images captured during analysis, graphs and statistics, and save your results as a csv, xlsx or pdf file.

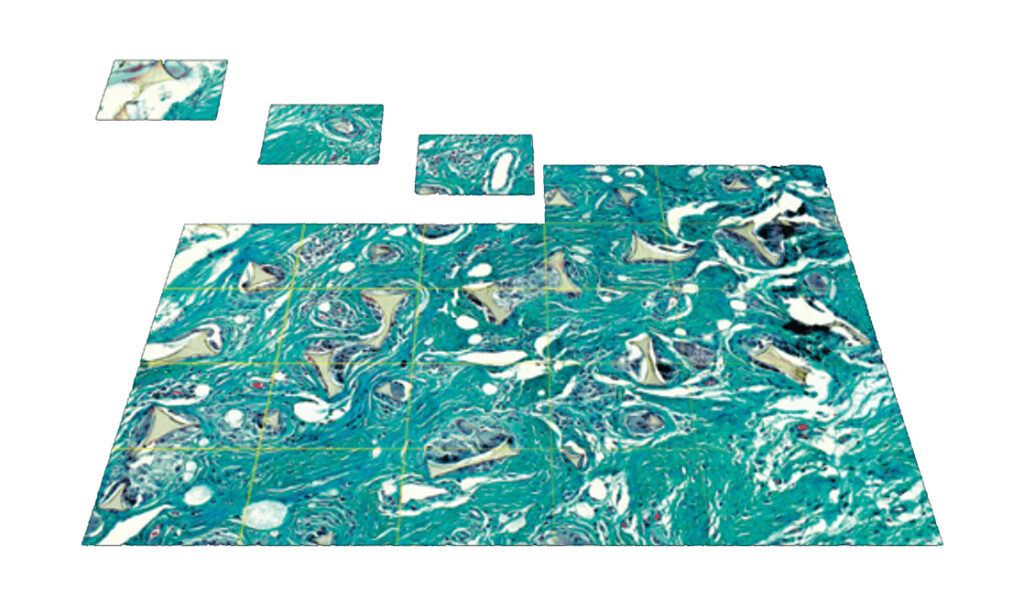

MOSAIC IMAGE STITCHING

Clemex Vision software automatically stitches multiple fields to form a seamless composite image of the whole sample which can then be analyzed and saved. This function can be used with a manual or motorized stage.