About us

AFFRI Inc is a leader in hardness testing equipment and an ILAC-MRA and ISO/IEC 17025 accredited laboratory.

We offer a classic product line under the AFFRI brand, along with a dedicated ATI line. Both lines include a wide range of innovative, high-precision instruments. Our solutions are designed to meet the needs of all industries, ensuring accurate and reliable results. Choosing us means relying on certified quality and proven experience.

Improve your laboratory and production line—from metallographic preparation to final testing. With our products, your hardness tests will always be reliable and compliant with the most stringent quality standards.

About us

AFFRI Inc is a leader in hardness testing equipment and an ILAC-MRA and ISO/IEC 17025 accredited laboratory.

We offer a classic product line under the AFFRI brand, along with a dedicated ATI line. Both lines include a wide range of innovative, high-precision instruments. Our solutions are designed to meet the needs of all industries, ensuring accurate and reliable results. Choosing us means relying on certified quality and proven experience.

Improve your laboratory and production line—from metallographic preparation to final testing. With our products, your hardness tests will always be reliable and compliant with the most stringent quality standards.

Hardness Testers: understanding material hardness

Hardness Testers: understanding material hardness

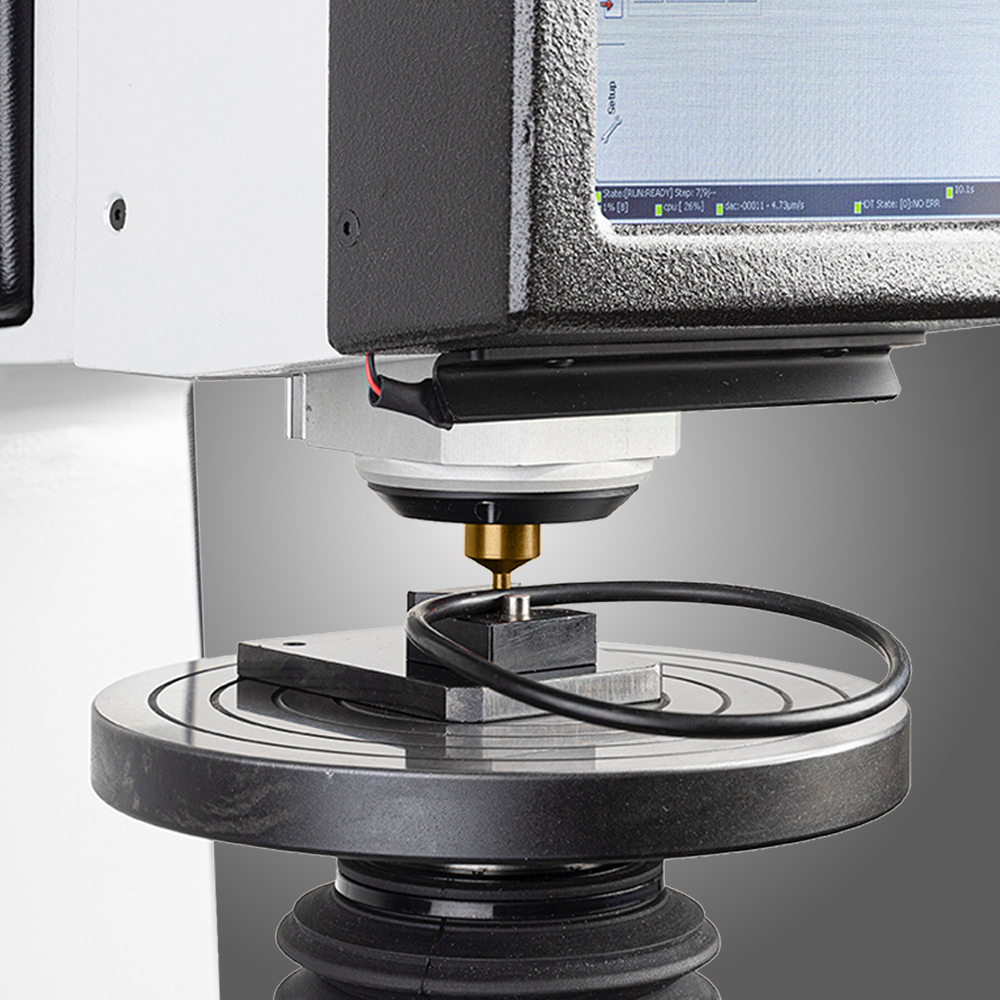

Hardness testers are precision instruments designed to measure the hardness of a material. Hardness is a fundamental property of a material that can vary depending on several factors, primarily the compactness and structure of the material. For instance, the hardness of steel can be altered through heat treatment processes, such as quenching. Quenching involves heating the metal to a high temperature and then rapidly cooling it, which causes the internal structure to change and become more compact, resulting in increased hardness. Conversely, if steel is heated and cooled slowly, its hardness decreases.

The hardness value of a material can also provide insights into other important properties, such as tensile strength. By measuring hardness, one can infer the material’s ability to withstand deformation or failure under stress. There are various methods for measuring hardness, each based on distinct principles: Brinell, Vickers, Knoop, Rockwell, Shore, and IRHD. Despite the differences in techniques, all methods follow the same basic principle: pressing a hard indenter into the material and measuring the extent of penetration. Each hardness testing method has its own procedure, which is governed by international standards. Among the most commonly adopted standards are:

- ISO/IEC 6506 (Rockwell hardness)

- ASTM E10 (Brinell hardness)

- ISO/IEC 6507 (Vickers hardness)

- ASTM E384 (Knoop hardness)

- ISO/IEC 2039 (Shore hardness)

- ISO/IEC 13843 (IRHD hardness)

These standards ensure consistency and reliability across testing procedures worldwide, allowing for accurate and comparable results. ATI offers comprehensive testing and calibration services for all types of hardness measurements, ensuring that your instruments meet the highest global standards. Our expertise and ISO 17025 accreditation provide you with confidence in the accuracy and quality of your testing processes.

Precision and Reliability for Every Need

Precision and Reliability for Every Need

The new ATI line of hardness testers represents the evolution of AFFRI’s technology and expertise. Designed for demanding daily use both in industrial settings and laboratories, our range of ATI Hardness Testers covers a wide array of hardness tests, including Rockwell, Brinell, Vickers, IRHD, and SHORE. These instruments offer exceptional performance and precision, guaranteed by our ATI Calibration Center, accredited to ISO/IEC 17025 standards with ILAC MRA certification. This ensures the highest level of accuracy, quality, and long-term service reliability. AFFRI Inc. provides certified, lifetime support for your durometer, ensuring continuous, reliable operation throughout its lifespan. We are also an accredited laboratory for the entire hardness testing chain, offering certifications for both machines and specimens (test samples) used in hardness testing. Our services extend beyond hardness, as we also certify forces for material testing machines (tensile, compression, torsion) and dimensional measurements.

As your trusted partner, AFFRI Inc. is committed to supporting you throughout your quality assurance journey. Our experienced technicians are available to advise you on the best solutions and products tailored to your specific needs, ensuring continuity and reliability over time. Our laboratory is equipped to perform verifications and certifications for all hardness scales and hardness testers, offering you comprehensive support in achieving precision and quality across your testing processes

Hardness Testers

A full range of ATI hardness testers conform to ISO and ASTM standards for material tests.

Rockwell

Rockwell hardness testers designed for precision and reliability. Our machines are optimized for Rockwell and Superficial Rockwell scales, offering robust solutions for industries requiring accurate and efficient hardness testing.

Brinell

Brinell hardness testers designed for precision and reliability. Our machines are optimized for testing large components and materials with coarse structures, offering robust solutions for industries requiring accurate and efficient hardness testing.

Vickers

Vickers hardness testers designed for unmatched precision and reliability. Our machines are optimized for micro and macro Vickers hardness testing, delivering accurate results for a wide range of materials and components across industries.

Universal

Universal hardness testers designed for unmatched versatility and precision. These machines combine Rockwell, Brinell, Vickers, and more hardness testing methods into one instrument, delivering accurate results for a wide variety of materials and applications across industries.

Portable

Portable hardness testers are suitable to test all hardness scales as per Rockwell, Brinell and Vickers measurements. From simple and pocket to automatic portable hardness testers conform to ASTM and ISO standards.

Plastics and Rubbers

Hardness testers for measurements on plastics and rubbers. Discover our wide range of solutions for rubber and plastics : from portable automatic hardness testers to automatic and motorized bench-top hardness testers conform to ASTM and ISO standards.

Universal Material Testing Machines

Our universal machines for testing materials can perform tensile, elongation, compression, bending and shear tests in order to offer the best solution.

Universal material testing machines

Our Universal Material Testing Machines are for all your needs. Wide Load range from 10N to 3'000 kN. Fully automated and accurate testing cycle. Universal testing machines can be equipped with a range of custom grips and fixtures tailored to specific materials or testing requirements

Torsion testing machines

Our advanced torsion machine are the solution for your needs. The machines are designed to accommodate various load capacities depending on the specific needs of the test, making them suitable for both small-scale laboratory use and large industrial applications.

extensometers

Our extensometer machines offer precise strain measurements for key material properties. With a wide measurement range and advanced software, they enable real-time analysis, customizable tests, and detailed reports for comprehensive material evaluation.

spring machines

Our spring testing machines deliver accurate measurements for essential spring characteristics. Featuring a broad testing range and advanced software, they allow real-time monitoring, flexible test configurations, and the generation of detailed reports for comprehensive evaluation of spring performance.

Other Solutions

AFFRI Inc. has solutions for your needs, ranging from metallographic sample preparation for hardness measurements to industrial microscopes and various image analysis solutions designed for our customers.

Metallographic sample preparation

Discover ATI machines for metallographic sample preparation. Our metallographic preparation machines are designed for precise and efficient sample preparation, offering robust solutions for industries that require high-quality surface finishes.

Image Analysis Solutions

Image Analysis Vision is an automated, highly precise, and versatile platform ideal for laboratories and industrial applications. These image analysis solutions are designed to analyze particle contamination, a critical concern in the manufacturing and pharmaceutical industries.

Industrial Microscopes

Discover our wide range of High-Precision Industrial Microscopes for Material Inspection and Analysis, they are designed to deliver reliable and consistent performance, ensuring the highest standards in production processes.