EASYDUR EASY PORTAL

CNC Portal Brinell Hardness Tester for Forges, Heat Treatments and Steel Factories

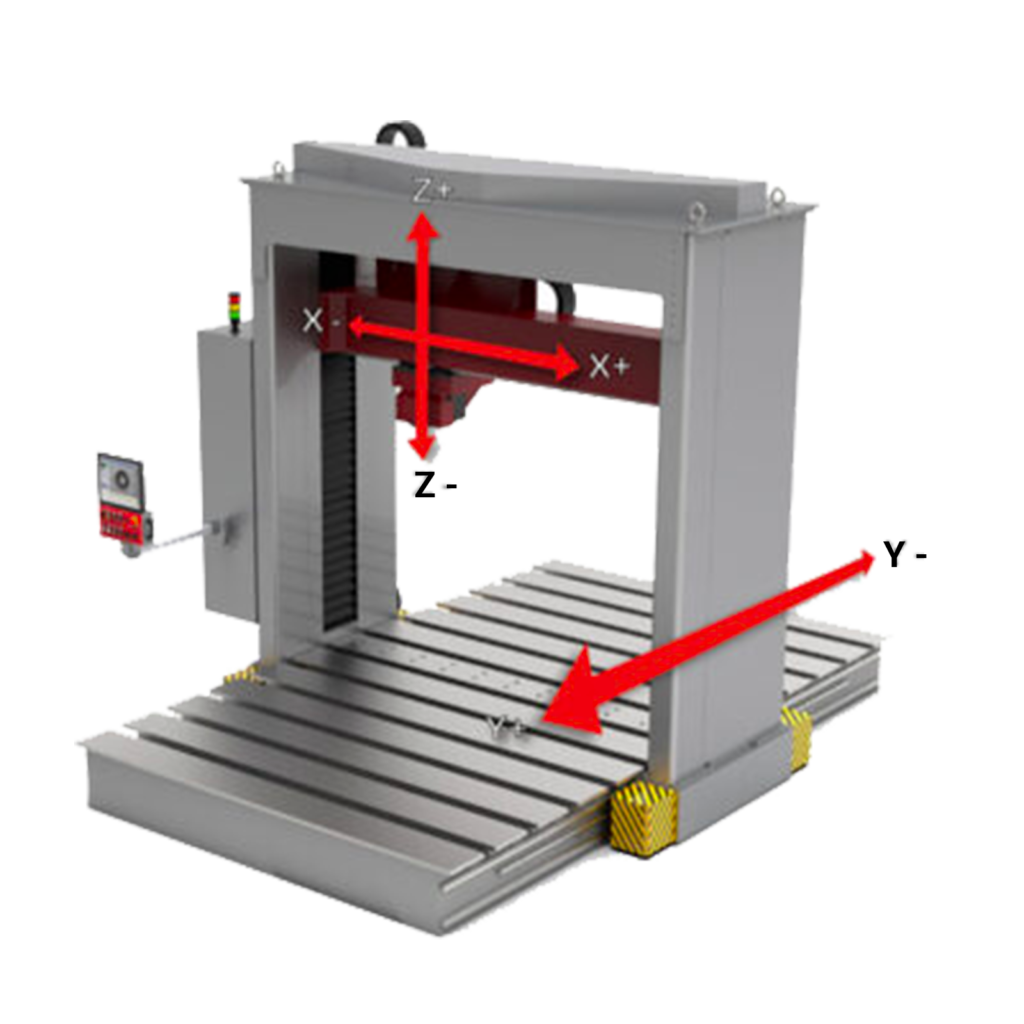

EASYDUR EASY PORTAL is an automatic CNC Portal Hardness Tester for very big parts. Suitable for forges, heat treatment and steel factories.Test loads from 10 kg to 3000 kg. The table (6000 mm long) is fixed and stable and has no weight or sample size limitations.A bridge structure moves on XYR axis to reach multiple test points with high precision. The software programs the turret movements and it’s possible to set an automatic sequence of measuring, milling and Brinell test cycle.

- TEST LOADS from 10 kgf to 3000 kgf (98.07 to 29421 N)

- BRINELL HBWT ISO 6506 / ASTM E-10 HBW 1/10 – HBW 1/30 – HBW 2.5/15.625 – HBW 2.5/31.25 – HBW 2.5/62.5 – 2.5/187.5 – 5/25 – 5/62,5 – 5/125 – 5/250 – 5/750 – 10/100 – 10/250 – 10/500 – 10/1000 – 10/1500 – 10/3000

- Rockwell and superficial Rockwell ISO 6508 / ASTM E-18 HRA – HRB – HRC – HRD – HRF – HRG – HRL – HRM – HRR / HRN – HRT

Flexible Testing in Every Dimension

Our design team develops tailored solutions for any application, utilizing cutting-edge technologies to ensure optimal efficiency and precision. We focus on creating advanced systems that meet the highest industry standards.

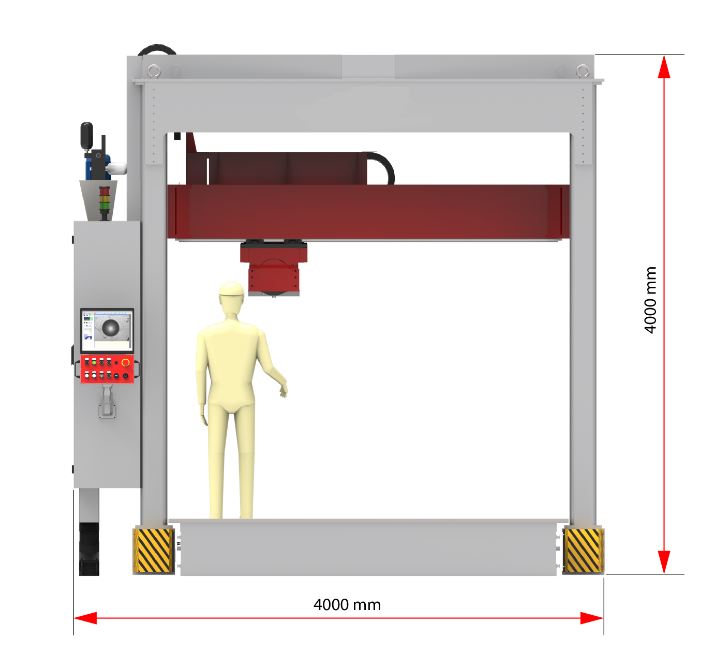

- Length: 16 meters (or more)

- Height: 5 meters (or more)

- Width: 4 meters (or more)

- Laser pointer for precise identification of test points

- Load accuracy: 0.05% with Closed Loop control

- Clamping system to securely hold the sample in place during testing

- Milling tool for surface preparation, featuring adjustable depth and RPM for maximum flexibility

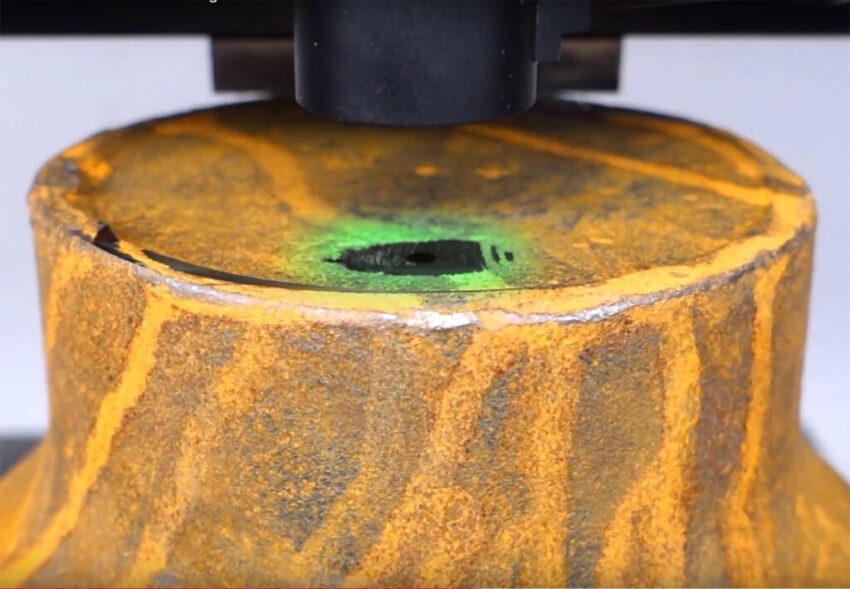

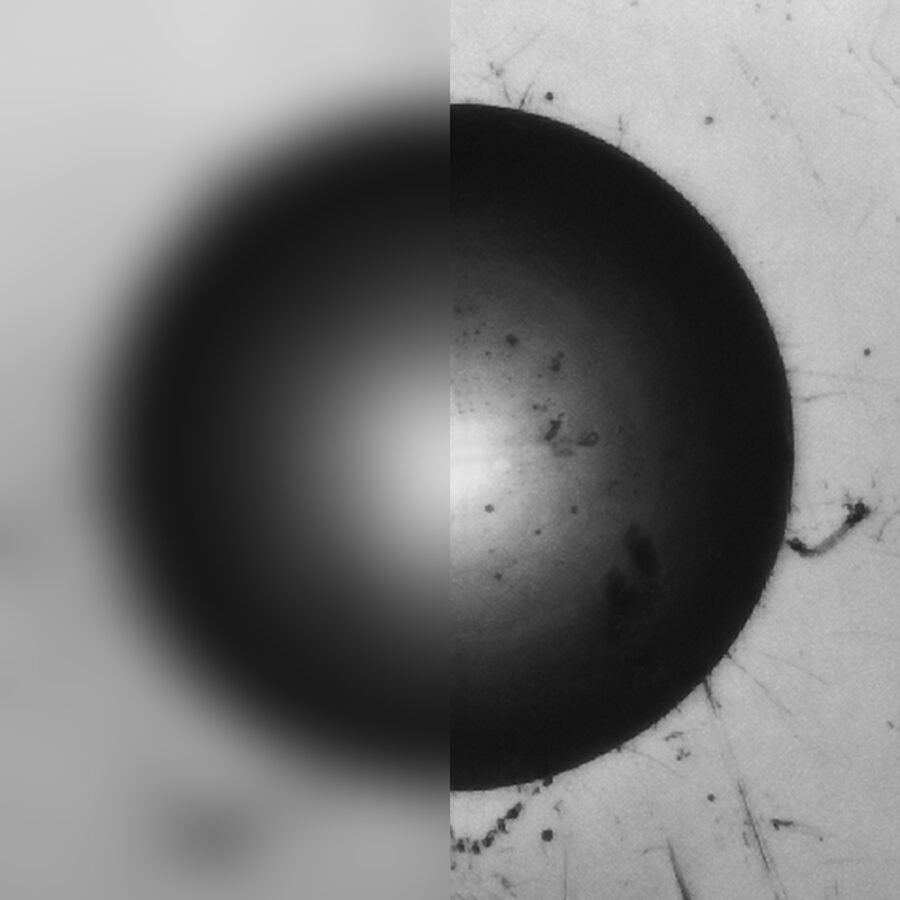

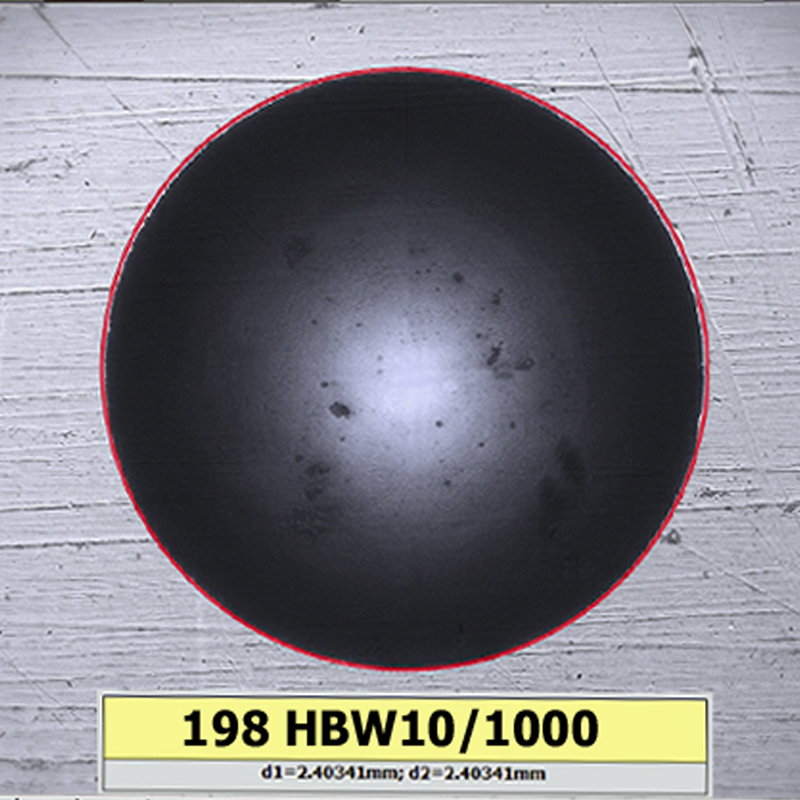

- Brinell measurement with high-resolution camera and autofocus for precise indentation reading

- Data acquisition and automatic hardness calculation for quick and accurate results

- On-screen display of real-time results for immediate feedback

- Archiving of images and data along with corresponding statistical analysis for future reference

This system provides an efficient, flexible, and highly accurate solution for a wide range of testing needs, offering seamless integration for various applications.

FAST, AUTOMATED, AND PRECISE TESTING WITH EASY PORTAL

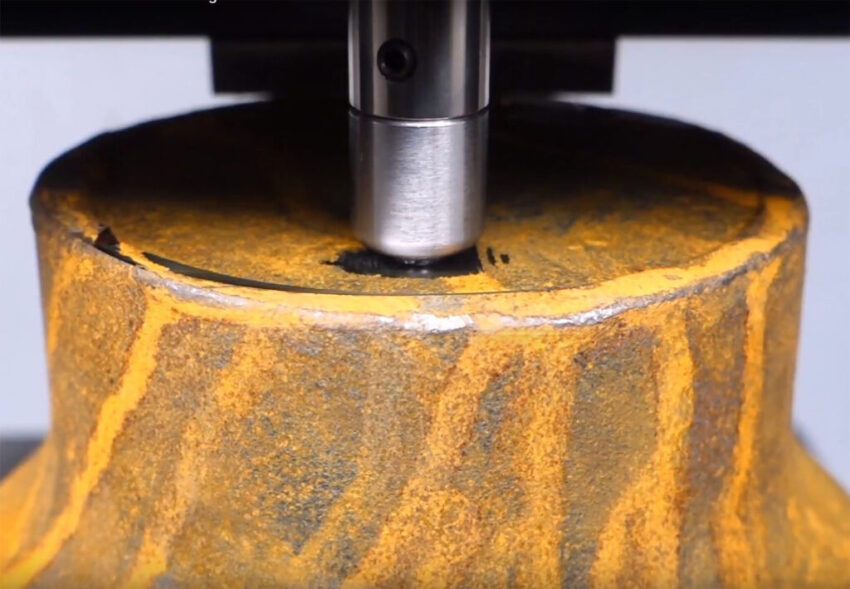

The entire testing process is completed in under one minute. All phases, including surface milling, indentation, and reading, are controlled by a single input command, ensuring maximum efficiency. Surface preparation is fully customizable, allowing users to adjust both the milling depth (up to 5 mm) and the RPM, depending on the material being tested. Our portal systems feature motorized axes that control the movement of the stand, crossbar, and measuring head, providing smooth and precise adjustments. Thanks to the sophisticated design of the measuring head, the Easy Portal is capable of testing small components or areas near the edges of parts. Simply press START and receive your results—fast, efficient, and fully automated.

MILLING

INDENTING

READING

SAVE TIME AND MONEY,

INCREASE ACCURACY

- 45 sec for one complete test including surface preparation

- Test 100% of production with maximum Brinell accuracy

- Automatize the quality inspection process

- Move human resources to other jobs

- Always the same surface roughness, no risk of damaging or heating the testing surface

- The total cost of the machine is absorbed in one year

MAIN FEATURES

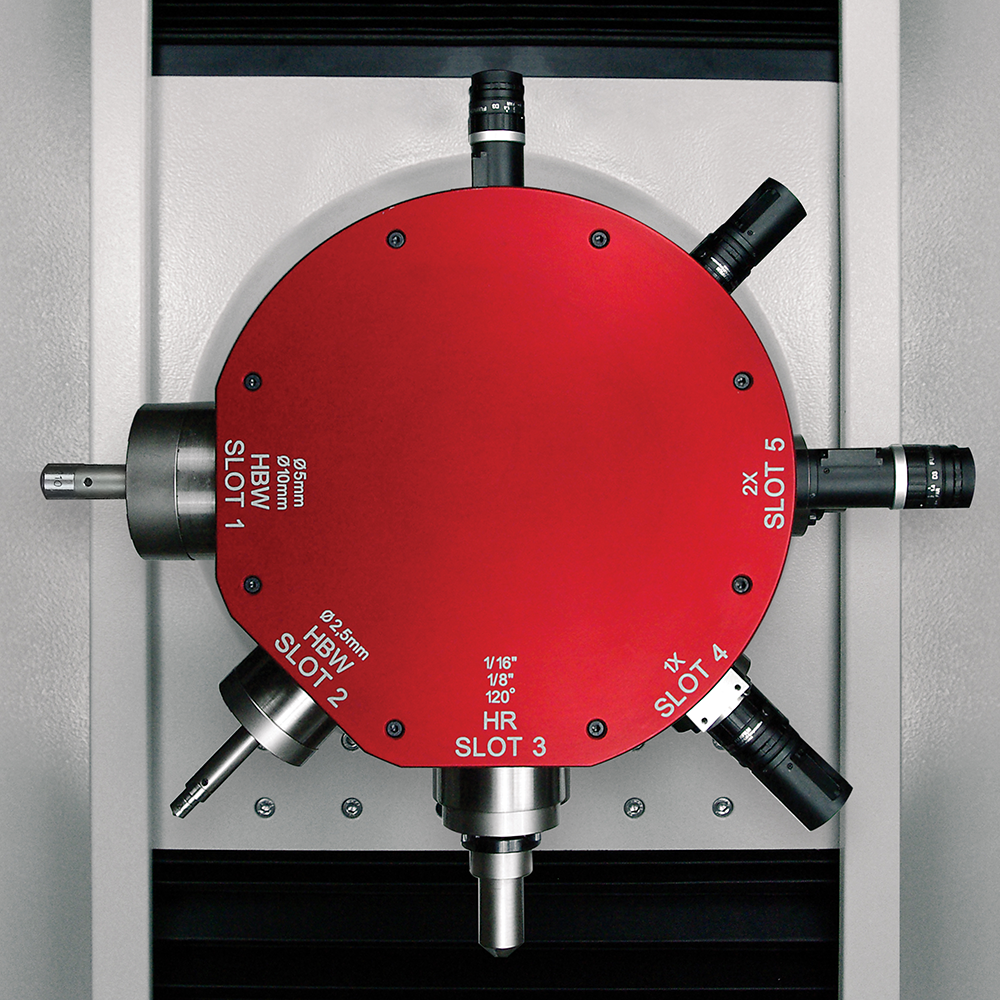

MOTORIZED TURRET

The system offers up to 8 slots (or more) for a variety of hardness scale indenters, different optical lenses, lasers, and even a milling tool for surface preparation. It includes automatic rotation and tool switching, ensuring a fully automated testing process. This allows for both single and multi-hardness testing with a single device.

MAIN FEATURES

CLAMPING SYSTEM

A secure connection with the specimen is guaranteed throughout the test, even in the rare case of specimen movement during the testing cycle. The clamping system ensures full stability of the test piece, regardless of its condition whether oiled, rusted, or contaminated with dirt throughout the entire testing process.

MAIN FEATURES

AUTO LEARNING SYSTEM

The Easy Portal 3000 is fully motorized and moves automatically in any direction with centesimal precision. It is possible to program specific routes to test multiple samples in automatic succession.

AUTOFOCUS

The automatic focus adjustment system for each optic ensures precise positioning at any magnification, utilizing real image brightness scanning with continuous steps for infinite accuracy. This technology guarantees high reading standards, reproducible focus values, and reduces reading time. Hardness measurements remain objective, unaffected by subjectivity.

AUTOFOCUS

The automatic focus adjustment system for each optic ensures precise positioning at any magnification, utilizing real image brightness scanning with continuous steps for infinite accuracy. This technology guarantees high reading standards, reproducible focus values, and reduces reading time. Hardness measurements remain objective, unaffected by subjectivity.

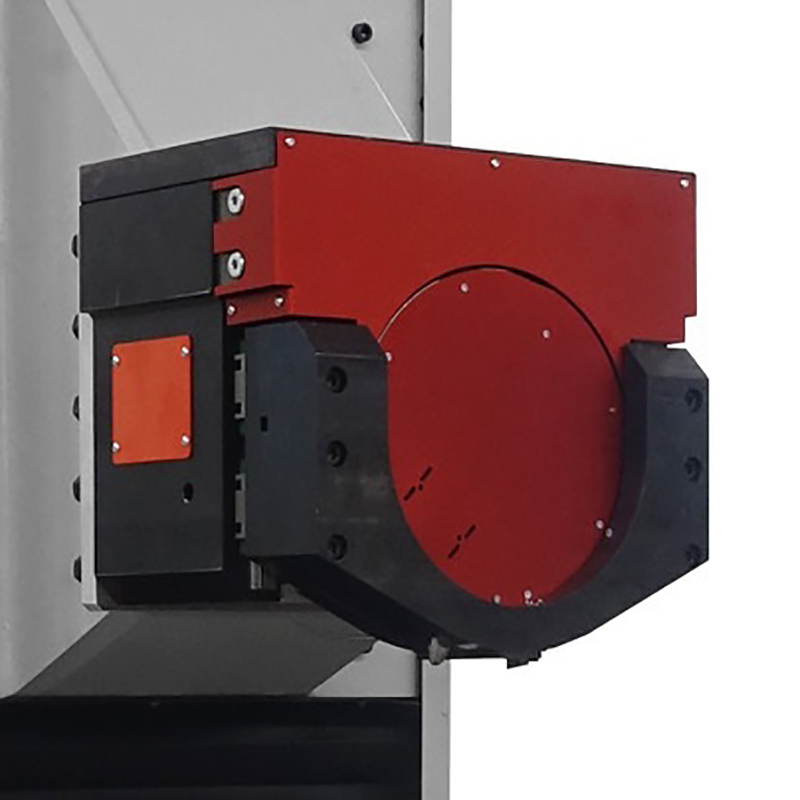

PORTALINO

A compact stand support offering the same motorization and features as the larger frame. It includes a base plate measuring 5100 x 4000 mm, with a working test height of 4000 mm. The frame is highly customizable to accommodate specific dimensional requirements, and the base can be seamlessly integrated beneath the floor for optimized space usage and stability. Ideal for environments where space is limited but precision and performance are still a priority.