Universal Torsion Testing Machines

Discover a complete range of universal torsion testing machines, perfect for any application, industry, and material type.

UNIVERSAL TORSION TESTING MACHINES FOR ALL NEEDS AND APPLICATIONS

Universal Torsion testing machines are essential tools for measuring the torque and mechanical properties of materials and components. These versatile instruments are widely used in industries ranging from automotive to manufacturing, helping to assess the durability, strength, and flexibility of various materials under torsional stress. Designed for high accuracy and reliability, torsiometers are key to ensuring product quality and performance.

Versatility in Testing

- Wide Range of Applications: Torsion testing machines can be equipped with various accessories to test a wide range of materials, including springs, specimens, wires, tubes, bars, and chains. These machines are ideal for testing both left-hand and right-hand torsion, making them highly adaptable.

- Component Testing: Torsiometers are also used in the component industry, including automotive applications, for testing parts such as knobs, collars, and selectors, assessing their performance under torsional forces.

Load Capacity and Configuration Options

- Variety of Models: Torsion testing machines are available in both bench-mounted and floor-standing models, allowing for flexibility based on testing requirements and space constraints.

- Customizable Load Capacity: The machines are designed to accommodate various load capacities depending on the specific needs of the test, making them suitable for both small-scale laboratory use and large industrial applications.

Types of Testing

- Torsion Testing: These machines can perform precise torsion tests, measuring the twisting behavior of materials and components under controlled conditions, both for right-hand and left-hand torsion.

- Breakage Testing: Torsiometers are capable of conducting breakage tests, helping to evaluate the maximum torsional strength of materials and components until failure occurs.

- Fatigue Testing: In addition to static testing, these machines can carry out fatigue tests, which simulate long-term torsional stress and provide data on how materials or components perform over time under cyclic loads.

Advanced Features and Automation

- Precision and Accuracy: Torsion testing machines are equipped with advanced measurement systems that ensure high precision, providing detailed and reliable data for material characterization.

- Automation Options: These machines can be integrated with automated systems to streamline testing processes, improve throughput, and ensure consistent results, making them ideal for both R&D and high-volume production environments.

Customization for Specific Industries

- Automotive and Component Testing: Torsiometers are used extensively in the automotive industry to test the torsional properties of components such as steering wheels, gears, and other mechanical parts. The machines can be customized with specific accessories to accommodate industry-specific testing requirements.

- Material-Specific Testing: Torsion testing machines can be equipped with specialized fixtures and sensors to test the behavior of different materials, from metals and alloys to polymers and composites.

ATI TOR

TORSION TESTING MACHINE

The ATI TOR is an advanced torsion machine designed for precise torsion testing, ideal for a wide range of applications in industries such as materials science, engineering, and quality control.

- Dual Linear Slide Design: Provides exceptional torsional stiffness and stability, allowing for consistent and accurate results across a variety of materials and tests.

- Operator Safety: The interlocked chuck guard offers added safety by protecting the operator from the rotating drive during operation, reducing the risk of accidents.

- Precision Torque Measurement: Torque is measured directly through a strain-gauged torque cell, providing enhanced accuracy for your testing needs.

- Comprehensive Torsion Testing Software: Our advanced software offers intuitive graphical data plots and performs a wide range of calculations, including torque and angle data analysis, ensuring in-depth insights into material behavior.

- Horizontal Tool Holder with T-Slots: The horizontal tool holder is equipped with T-slots on linear displacement, providing flexible and secure attachment for test specimens, and is easily fixable for a variety of setups.

SOFTWARE

Software package under English version of Windows platform, with simple user-friendly interface. Dynamic display of data: The data during the test pro- cess (such as: torque, twist angle, stroke etc.) will be displayed in real time. Ability to recall, report, and rescale curves. User configurable testing method: specimen information, controlling methods and measuring method can be con- figured saved according to varied materials for future needs. User configurable report: MS. EXCEL report formats can be freely tailored to different report templates. Multiple control modes: It has stroke control, torque control, twist angle control, stress control, and shear strain control etc. result conclusion: Torsional strength, yield strength, upper yield strength, lower yield. Strength, Max. Torque, proof stress of non- proportional torsion, Max. non- proportional shear. Strain, shear modulus, twist angle for the corresponding torque and torque for the corresponding twist. Angle etc. Multiple statistics function average value, standard deviation, coefficient of variation, Max. User can edit and define the test results directly on the curve to improve uncertainties.

WHY CHOOSE ATI TOR

- Accurate and Reliable Results: With its high-torsional stiffness and precision torque measurement, the ATI TOR guarantees reliable test data for material testing, quality assurance, and product development.

- Enhanced Safety Features: The interlocked chuck guard and robust design prioritize operator safety during testing, giving you peace of mind in any environment.

- Advanced Software Capabilities: The comprehensive software included with the ATI TOR allows you to analyze test results through detailed graphical representations and in-depth calculations, helping you make informed decisions.

The ATI TOR is a powerful tool for engineers, researchers, and manufacturers seeking high-performance torsion testing equipment. Whether you are testing small components or larger materials, the ATI TOR delivers the precision, accuracy, and safety you require for successful torsion tests.

| MODEL | ATI TOR |

| Compliance Standards: | ASTM A938 Torsion Testing of Wire, ASTM D7860-14 Torque Retention for Child Resistant Packaging, ASTM F543 Metallic Medical Bone Screws, ASTM F1717 Spinal Implant Constructs, ASTM F2346 Characterization and Fatigue Testing of Spinal Intervertebral Disc Prostheses, IEC 888 Zinc Coated Steel Wires and ISO 7800 Torsion Testing Wire |

| Measuring Range: | 500 Nm |

| Torque Resolution: | 0.5 Nm |

| Clearance Resolution: | 500 mm |

| Torque Resolution: | 1/50000 |

| Relative Error of Torque: | ±0.5% |

| Relative Error of Torsion Angle: | ±0.5% |

| Torque effective test range(F·S): | 0.4%~100%F·S |

| Resolution of torsion angle: | 0.002° |

| Test Accuracy of Torsion Angle: | ≤±0.5% |

| Torsion Speed: | 0.01~1500°/min (can be customized) |

| Protection Function: | The tester has overload protection function |

| Twist Appendage: | Three jaw chuck type, two – way roof tightness |

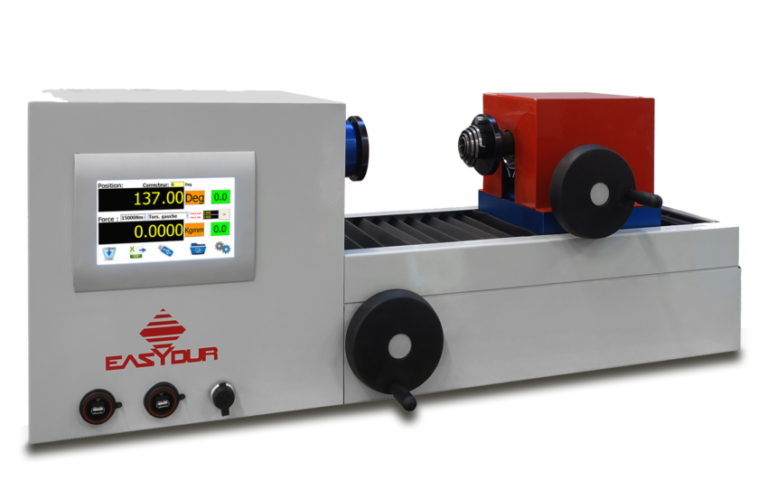

EASYDUR TM Torsion Meter

UNIVERSAL MATERIAL TESTING MACHINE

EASYDUR TM Torsion Meter is an advanced torsion testing machine for micro to high loads, featuring friction-free movement, high precision, and bidirectional load cells. It operates via a microcomputer in a Windows environment, with an intuitive touch panel and Ethernet connectivity. The machine supports multiple twist positions, self-zero recognition, and product scanning with Q reader. It also offers continuous assistance, calibration, and data transmission, with pre-inserted multi-cells for immediate use.

MAIN FEATURES

- High Accuracy: Ultra-sensitive torque measurement with 1ms sensitivity, 100,000 divisions, and 0.1° precision.

- Fast Measurements: Supports single and rapid multi-position measurements with auto-zero recognition.

- User-Friendly Software: Intuitive, no manual or training required.

- Guided Test Procedure: Automated process for data collection, analysis, and report generation with customizable filters.

- Data Storage: Stores data in a high-capacity database for repetitive test cycles.

- Custom Accessories: Wide range of customizable accessories for various tests.

| MODEL | TM02 | TM04 | TM1 | TM2 | TM4 | TM10 | TM20 | TM500 |

|---|---|---|---|---|---|---|---|---|

| Usable Capacity Nmm | 200 | 400 | 1.000 | 2.000 | 4.000 | 10.000 | 20.000 | 500.000 |

| MIN division Nmm | 0.008 | 0.015 | 0.04 | 0.08 | 0.15 | 0.4 | 0.8 | 0.8 |

| Spring diameter | 200 mm | |||||||

| Opening between the plates | 150 mm | |||||||

| Performable rotations | 27 | |||||||

| MIN corner division | 0.1° | |||||||

| Power supply | 220 V , 50/60 Hz , 200 VA | |||||||

EASYDUR TR Torsion Meter

UNIVERSAL MATERIAL TESTING MACHINE

EASYDUR TR Torsion Meter is a next-generation torsion testing machine for medium and micro loads, featuring manual control, double recirculating ball guides, and friction-free movement for high sensitivity. It operates via a microcomputer with Windows 10 and uses an Affri loop system with bidirectional load cells. The machine has a high-definition color screen, intuitive touch controls, and Ethernet connectivity for data transfer and remote assistance. It supports positive and negative twist measurements at multiple positions, self-recognition of the zero position, and product scanning with a Q reader. Pre-inserted multi-cells are available for immediate use.

MAIN FEATURES

- Ultra-precise torque measurement: 1ms sensitivity, 100,000 divisions, and 0.1° accuracy.

- Fast multi-position measurements: Includes auto zero recognition.

- User-friendly software: Simple, intuitive, requiring no manual or training.

- Guided test procedures: Includes data collection and processing for detailed diagrams and reports, customizable by the user.

- Designed for various test cycles: Suitable for springs and other materials; stores data in a comprehensive database for repetitive cycles.

- Customizable accessories: Wide range of accessories for different tests, available in the data sheet.

| MODEL | TR02 | TR04 | TR1 | TR2 | TR4 | TR10 | TR20 |

|---|---|---|---|---|---|---|---|

| Usable Capacity Nmm | 200 | 400 | 1.000 | 2.000 | 4.000 | 10.000 | 20.000 |

| MIN division Nmm | 0.008 | 0.015 | 0.04 | 0.08 | 0.15 | 0.4 | 0.8 |

| Spring diameter | 200 mm | ||||||

| Opening between the plates | 150 mm | ||||||

| Performable rotations | 27 | ||||||

| MIN corner division | 0.1° | ||||||

| Power supply | 220 V , 50/60 Hz , 200 VA | ||||||