ATI IN

ATI IN is a Rockwell hardness tester with built-in image viewing. ATI IN is represents the ideal solution, the indenter has been specifically designed to reach deep cavities. This allows you to measure hardness on parts that cannot be measured with a traditional hardness tester.

ATI IN is the solution for hardness tests on components such as rings and tubes (with a minimum internal test diameter of 25 mm) or near flanges or shoulders. The new structure of the indenter allows a direct view of the test point.

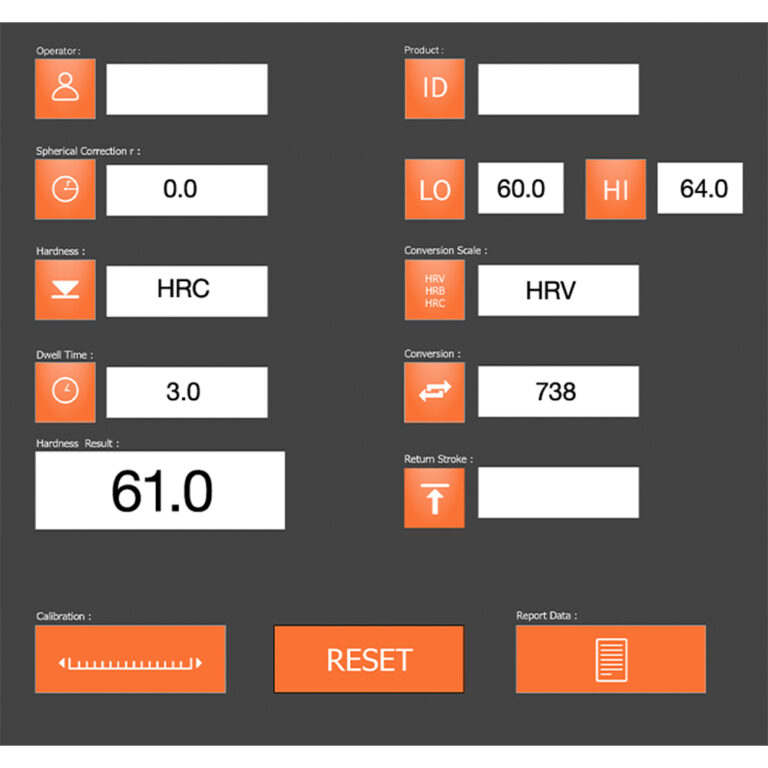

A single START button to start the entire test cycle: when the indenter comes into contact with the surface to be tested, the hardness test phases will begin in automatic succession without interruptions. Preload and load are managed electronically in “Closed-Loop” combined with an electronic load cell system. Each step of the test cycle appears automatically on the touch screen display built into the body of the hardness tester. The measurement software is intelligent and easy to use: select the hardness scale, the force value is automatically changed according to the preset test parameters

SOFTWARE

The entire test cycle apperas in real time on the screen incorporated into the hardness tester, which offers a direct view of the indentation. The ATI IN hardness tester software is easy to use thanks to the intuitive menu and buttons. It is possible to customize the templates. With the variety of indentation display screens, you can keep under control every detail of the hardness test and monitor the entire test cycle. Hardness test results are directly converted to multiple scales HR, HB, HV. Large internal memory for data saving, statistical creation and saving in EXCEL format. Any data collected can be edited, processed and exported via USB.

SPECIAL SHAPE INDENTER

ATI IN is the solution for performing Rockwell and Brinell hardness tests on hollow samples and their internal parts thanks to the complete visibility of the indenter. It is possible to perform hardness measurements on shoulders, teeth and profiles. These features make ATI IN superior to conventional hardness testers, surpassing them in application fields.

| Model: | ATI IN |

| Compliance standards: | ISO 6508, ASTM E18, BSEN 6508, GB/T230 |

| Rockwell initial test force: | 3 – 10 kg (29.4 N – 98.07 N) |

|

Rockwell total test force:

|

60 – 100 – 150 kgf (588 – 80 – 1471 N) |

| Superficial Rockwell total test force: | 15 – 30 -5 kgf (147.1 – 249.2 – 41.3 N) |

|

Rockwell hardness scale: |

HRA ,HRB, HRC, HRD, HRE, HRF, HRG, HRH, HRK, HRL, HRM, HRR, HRP, HRS, HRV |

|

Superficial Rockwell hardness scale: |

15N, 15T, 15W, 15X, 15Y, 30N, 30T, 30W, 30X, 30Y, 45N, 45T, 45W, 45W, 45X, 45Y |

| Rockwell measurement range: | HRA: 20 – 88, HRB: 20 – 100, HRC: 20 – 70, HRD: 40 – 77, HRE: 70 – 100, HRF: 60 – 100, HRG: 30 – 94, HRH: 80 – 100, HRK: 40 – 100, HRL: 100 – 120, HRM: 85 – 115, HRR: 114 – 125 |

| Superficial Rockwell measurement range: | HR15N: 70 – 94 , HR30N: 42 – 86 , HR45N: 20 – 77 , HR15T: 67 – 93 , HR30T: 29 – 82 , HR45T: 1 – 72 |

| Force control system: | Electronic control of load cells in “Closed-Loop” |

| Dwell time: | 1-99 seconds |

| Hardness resolution: | 0.1 HR |

| Force error: | <1.0% |

| Height capacity: | 300 mm |

| Depth capacity: | 250 mm |

| Minimum inner diameter: | 25 mm |

| Power supply: |

200V / 200VA , 50~60 Hz |

| Total dimensions: | 720 x 260 x 840 mm |