UNIVERSAL EXTENSOMETERS

Discover a complete range of universal extensometers, perfect for any application, industry, and material type.

UNIVERSAL EXTENSOMETERS FOR ALL NEEDS AND APPLICATIONS

Extensometers are essential tools for accurately measuring the deformation and strain of materials under mechanical stress. Widely used in both research and industrial applications, these devices provide precise measurements critical for material testing. Whether for tensile, compression, or other mechanical tests, extensometers enable a deeper understanding of material behavior, allowing for better product design and quality control.

Precision and Measurement Capabilities

- Accurate Strain Measurement: Extensometer machines are designed to measure small changes in length (strain) in materials when subjected to mechanical stress. This makes them crucial for determining key material properties such as tensile strength, elasticity, and ductility.

- Wide Measurement Range: These machines can be configured to measure a wide range of strains, from very small deformations in high-precision tests to larger strains in more robust materials.

Types of Extensometers

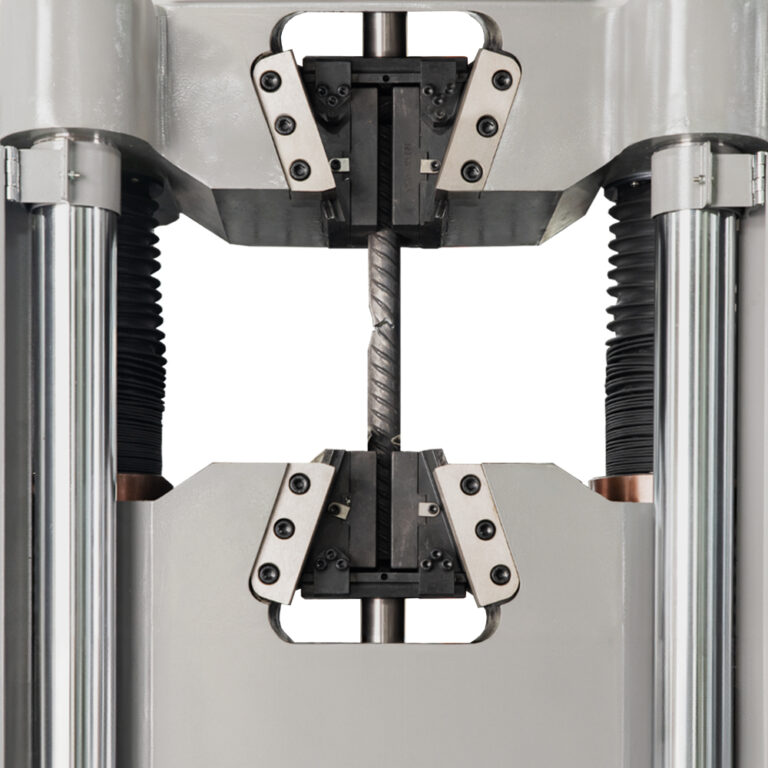

- Mechanical Extensometers: These traditional devices use mechanical components to measure deformation. They are highly durable and suitable for a variety of testing environments.

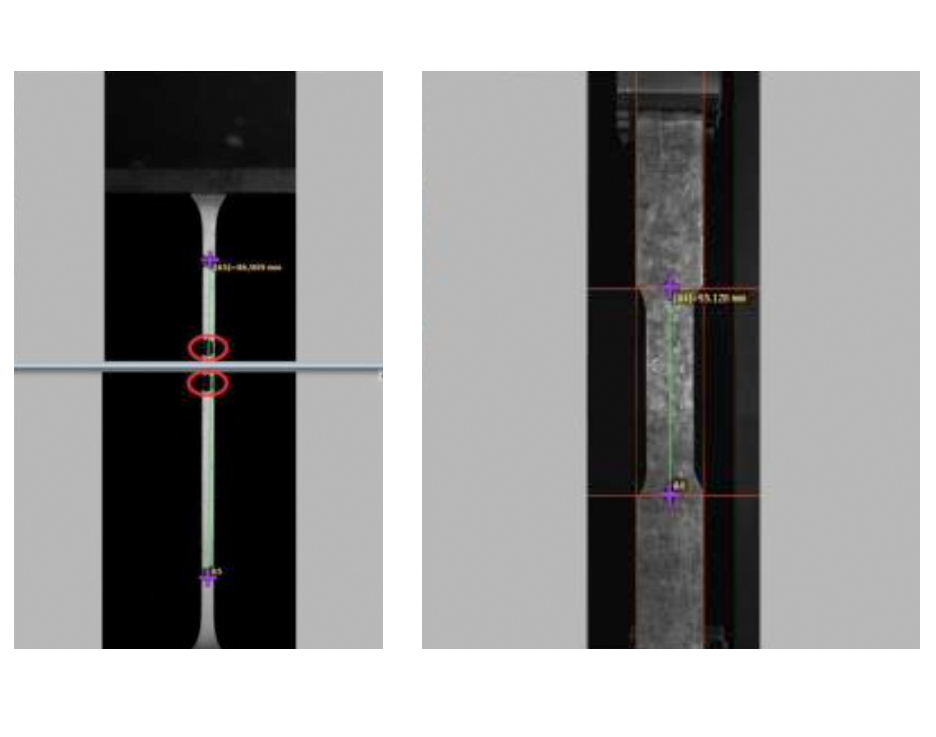

- Video Extensometers: Offering non-contact measurement, video extensometers use optical systems to monitor deformation, providing high accuracy and eliminating the risk of interference with the sample during testing. This type is ideal for high-precision testing.

- Clip-On Extensometers: These are designed for easy attachment to test specimens and are used for materials that require direct contact for strain measurement.

Versatility and Compatibility

- Flexible Applications: Extensometer machines are compatible with a wide range of testing setups, including tensile, compression, and bending tests. By simply adjusting the accessories or sensors, they can be used for various materials, from metals and polymers to composites and ceramics.

- Adaptable for Different Specimens: Depending on the material being tested, extensometers can be customized with different grips or contact points to ensure accurate measurements, regardless of specimen size or shape.

Integration with Testing Machines

- Seamless Integration: Extensometers can be easily integrated with universal testing machines, providing real-time strain measurements alongside force data. This integration enhances the accuracy and reliability of the overall testing process.

- Data Synchronization: When paired with advanced testing software, extensometers allow for synchronized data collection, enabling users to analyze both stress and strain data simultaneously for a complete picture of material behavior.

Software and Automation

- Advanced Software: Extensometer machines come with specialized software that allows users to program and control testing routines, collect strain data, and analyze material behavior under various conditions. The software also enables the generation of detailed graphs and reports.

- Real-Time Data Analysis: The software provides real-time feedback during tests, making it possible to track material deformation continuously and adjust testing parameters as needed.

- Industry 4.0 Compatibility: These machines can be integrated into Industry 4.0 environments, supporting automated data collection, analysis, and reporting, improving efficiency and traceability in material testing workflows.

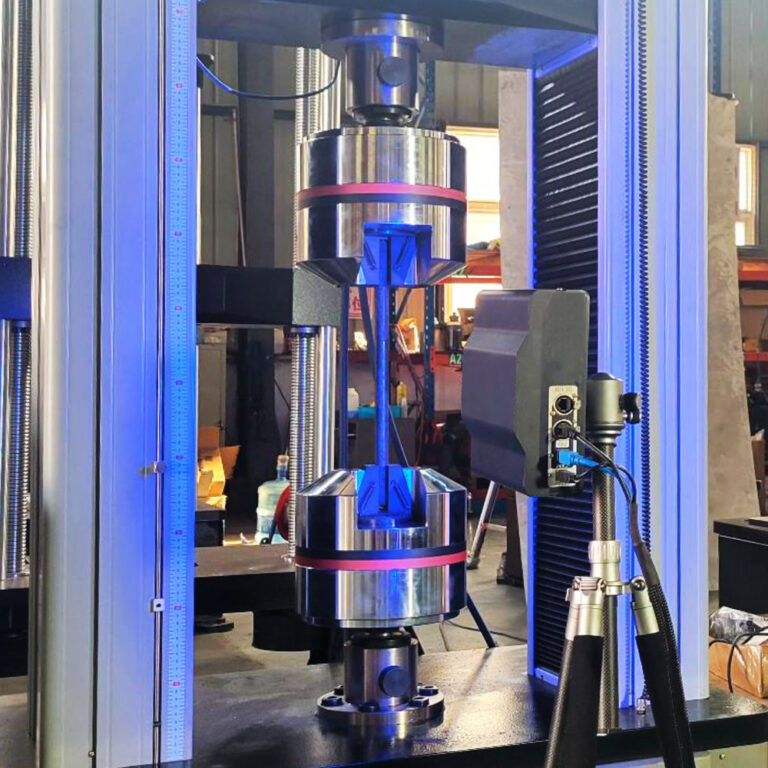

ATI EXT

VIDEO EXTENSOMETER

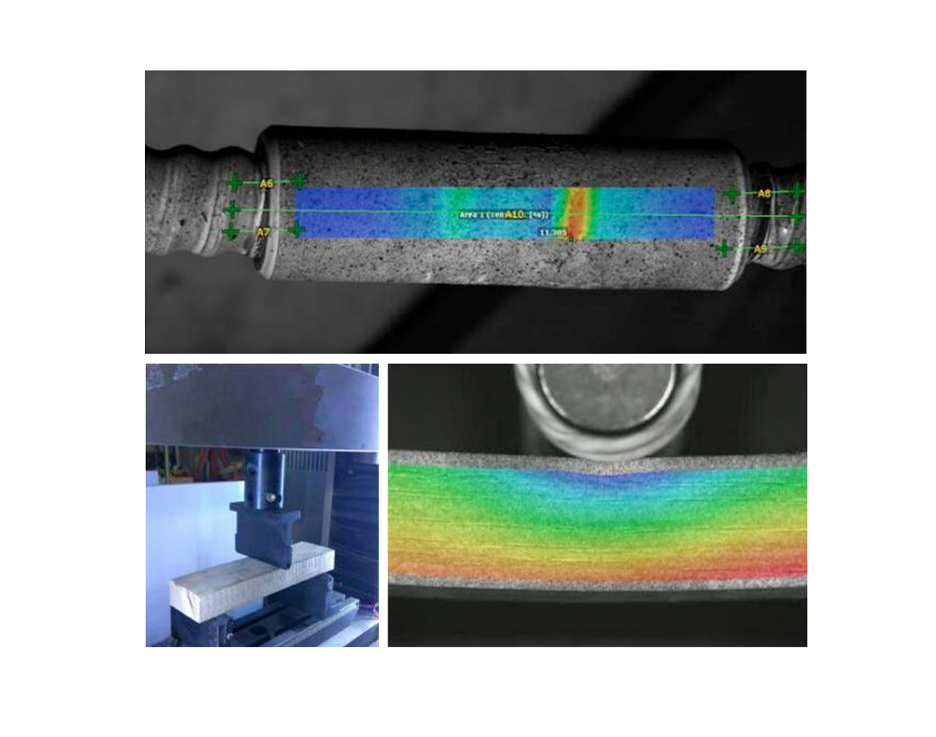

The ATI EXT is a video extensometer featuring an optical non-contact three dimensional deformation measurement system based on the Digital Image Correlation (DIC) method. This innovative technology enables precise measurement of both 2D and 3D strain properties in various materials and components, making it an invaluable tool in material testing. Designed for versatility, the ATI EXT can be utilized for testing and displacement measurement of 3D profile displacement deformation in a wide range of metals and non-metals. Its capability to handle static and dynamic deformation tests ensures comprehensive analysis, catering to the demands of modern engineering applications. With its non-contact measurement approach, ATI EXT minimizes interference with the test specimen, allowing for more accurate results. This feature is particularly beneficial in sensitive applications where traditional methods may alter the material behavior. ATI EXT stands out as a reliable solution for engineers and researchers seeking high precision in deformation measurement. Its advanced DIC technology and adaptability across various testing scenarios make it an essential instrument for enhancing quality assurance and driving innovation in material science.

MAIN FEATURES

- Non-contact measurement

- Real-time strain measurement

- Curve representing the stress-strain relationship

- Calculation of material performance

- Default measurement length: 110mm (220mm)

- Default resolution according to ISO9513: Class 0.5 / Class 1

- Default resolution according to ASTME83-10: Class B-1 / Class B-2

- Gauge length: single or multiple points selectable L0

- Data acquisition rate: 75-500 Hz

- Transverse measurement: optional transverse or biaxial axial and radial neck detection

- Output: digital and analog

- Lighting: Automatically switching monochromatic light

- Integrated software: via strain gauge user interface

- Mounting: test frame, camera or tripod

THREE POINT BENDING TEST

COMPONENT TESTING

| Model: | ATI EXT |

| Measurement Range: | ASTM E38 Class B1 or ISO 9513 Class 0.5 standards |

| FOV: | Calss 0.5: 100 ; Class 1: 200 mm |

| Gage Length: | 0.01 – 800 % |

| Resolution: | FOV 100 mm : 0.5 μm ; FOV 200 mm :1 μm |

| Camera Resolution: | 2.3 MPx |

| Number of Camera: | 1 |

| FPS at Full Resolution: | 43 Hz |

| Interface: | USB |

| Standard Accessories: | USB output for light control and data cables. Electric supply. Hardware license key. Calibration grid (based on application). Camera lens (typically 16mm). Power cord. Monochromatic LED lights. |