Universal Material Testing Machines

Discover a complete range of universal material testing machines, perfect for any application, industry, and material type.

UNIVERSAL MATERIAL TESTING MACHINES FOR ALL NEEDS AND APPLICATIONS

Universal Material Testing Machines are indispensable tools for material characterization, widely used in laboratories and industries across the globe. These versatile systems are capable of performing a wide range of mechanical tests, from tension and compression to bending, cutting, and elongation. Whether for quality control, research, or development, universal testing machines provide precise and reliable data for assessing the mechanical properties of materials.

Wide Range of Testing Capabilities

- Versatile Testing: Universal testing machines can perform a variety of mechanical tests, including tensile, elongation, compression, bending, and shear tests. By simply changing accessories, they can accommodate different testing needs.

- Material Characterization: These machines are designed to measure essential material properties such as yield strength, tensile strength, elastic modulus, and deformation, providing comprehensive data for material analysis.

Load Capacity and Configuration

- Various Load Ranges: Universal testing machines are available in different load ranges to suit a wide range of applications:

- Low Load: For loads ranging from 10 N to 5 kN.

- Medium Load: For loads up to 50 kN.

- High Load: For loads up to 3,000 kN, ideal for testing heavy-duty materials.

- Load Cell Configuration: These machines can support up to three selectable load cells, which can be easily configured using the machine’s dedicated software, allowing for precise measurements across varying load conditions.

Software and Automation

- Advanced Software: The included software is highly versatile and customizable, enabling users to program and store testing routines, generate and export graphs, and create customized reports.

- Industry 4.0 Integration: The software is designed to work seamlessly with Windows 10/11 systems and can be integrated into an Industry 4.0 environment, ensuring full compatibility with modern manufacturing and testing processes.

- Real-Time Data Analysis: The software allows for real-time analysis of material reactions to mechanical stimuli, supporting research and development efforts without the constraints of predefined standards.

Specialized Accessories and Customization

- Custom Fixtures and Grips: Universal testing machines can be equipped with a range of custom grips and fixtures tailored to specific materials or testing requirements, ensuring secure and accurate testing setups.

- Temperature Control: For tests that require temperature-sensitive conditions, optional accessories like furnaces and climate chambers can be added to perform tests at different temperatures.

- Extensometers: These machines can be fitted with various types of extensometers, including mechanical and video extensometers, to measure strain with high precision during tests.

ATI UTM-HTL

UNIVERSAL MATERIAL TESTING MACHINE

ATI UTM-HTL is a measurement and control system engineered for highprecision applications, featuring three dedicated analog input channels: one for load, one for an electronic extensometer, and one for expansion measurement. Each channel utilizes independent 24-bit A/D conversion chips, enabling high precision data sampling with a maximum resolution of ±1/500,000, ensuring that the full resolution is consistently maintained. To enhance measurement accuracy and range, the system incorporates up to 15 segments of linear compensation and correction functions. This capability significantly extends the measurement range and precision of the connected sensors, providing users with reliable and accurate data across various testing scenarios.

LOAD FRAME AND LOAD WEIGHT SYSTEM

This testing machine is designed for materials like rubber, plastic, wire, and more, suitable for tensile, compression, bending, and other mechanical tests in varying temperatures. It’s ideal for R&D, quality control, and industrial applications. The load frame features ergonomic design for safety and flexibility, with strong crosshead guidance and high-accuracy load cells. It includes a preloaded ball screw for precise, high-speed measurements and automatic safety stops at the end of the cycle or if force exceeds limits. The system ensures accurate load measurements, with calibration within 0.5% accuracy and protection against overloads up to 150%. It meets global standards and provides impact-resistant, durable load cells, ensuring reliability in demanding environments.

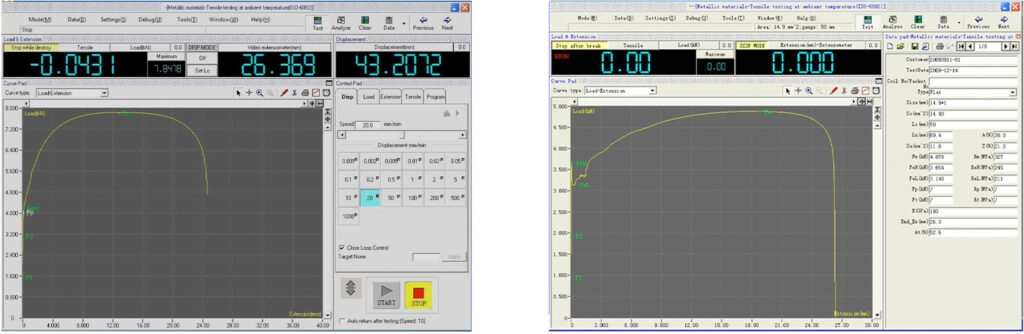

SOFTWARE

Our digital control system allows precise adjustments of parameters like zero points, load, deformation, and displacement. It features an intuitive interface, closed-loop control, and advanced graphic functions for curve visualization and analysis. Users can print and evaluate curves, and easily compare test results with interactive tools. The system includes a multilevel identity management system for secure, customized user access, and stores test data in a secure database. It supports report generation in Excel, Word, and custom templates, with options to add company logos and names. The system enhances efficiency, collaboration, and security, making it an essential tool for professionals.

MAIN FEATURES

The system includes three photoelectric encoder channels, four frequency input channels, and eight switch input interfaces for flexible monitoring of static and dynamic measurements. It uses an EDCH controller with a USB plug-and-play interface for fast, real-time data communication and control. The system supports multiple force and deformation sensors, allowing users to switch sensors based on testing needs, ensuring adaptability for various applications.

APPLICATIONS

This testing machine is suitable for rubber, plastic profile, plastic pipe, sheet, film, wire and cable, waterproof coil, wire and other materials in high or low temperature environment, tensile, compression, bending, peeling, tearing, shear and other mechanical properties of the test. It’s very convenient for users to carry out research and development, quality control work. It’s the right instrument for industrial and mining eneterpries, scientific research units, colleges and universities quality departments

| MODEL | ATI UTM-HTL |

| Load Capacity: | 5 kN (WDW-5HTL), 10 kN (WDW-10HTL), 20 kN (WDW-20HTL), 30 kN (WDW-30HTL), 50 kN (WDW-50HTL), 100 kN (WDW-100HTL) |

| Load Accuracy: | Class 0.5 |

| Testing Load Accuracy: | ± 0.5% |

| Load Resolution: | 1/5000,000 FS |

| Deformation Accuracy: | ≤ ± 0.5% of 0.4% ~ 100% of rated capacity |

| Position Resolution: | 0.025 μm |

| Position Accuracy: | ±0.02mm or 0.5% of displacement |

| Crosshead Speed Range: | 0.001-1000 or 0.001-500 (depending by models) |

| Crosshead Speed Accuracy: | ± 0.5% of set speed |

| Crosshead Travel (mm): | 1000 mm or 1100mm (depending by models) |

| Max Tensile testing space: | 670 mm or 770 mm depending by models |

| Max Tensile Testing Space: | 900 mm or 1000 mm depending by models |

| Test Width: | 450 mm or 550 mm depending by models |

| Compression Plate: | 98 mm |

| Position Limit Switch: | Upper and lower lights |

| Load Cells: | High precision load cell for the highest stability, linearity and stiffness. Over load protection, lateral loading protection, bidirection allows tension and compression test self-recognition function. Regular self-calibration. |

| Power supply: | AC 220V ± 10%, 50Hz / 60Hz |

| Total dimensions: | 850 X 590 X 1750 mm or 840 X 570 X 1850 mm or 950 X 660 X 2000 mm depending by models |

| Operative Temperature Range: | From +10°C to +300°C (WDW-5HTL), From -40°C to +300°C (WDW-10HTL), From -60°C to +300°C (WDW-20HTL), From -80°C to +300°C (WDW-30HTL), From -100C to +300°C (WDW-50HTL), From -190°C to +300°C (WDW-100HTL) |

| Colling System: | Compressor |

| Temperature Uniformity: | < 200 ≤ +2°C, ≥ 200 ≤ ± 3,5°C |

| Temperarure fluctuation: | ≤ ±1°Cz |

| Max Limit Temperature: | +300°C |

| Heating rate: | 2-3°C / min |

| Power supply: | AC 220V |

| Material of inner box: | Stainless steel |

| Material of outer box: | Stainless steel |

| Heating System: | Nickel-chromium alloy heating wire heater |

| Insulation materials: | Ultra-fine glass wool or rigid foam |

| Air supply circulation system: | A) monitor B) lenghtned shaft C) centrifugal fan |

| Compliance Standards: | Load meets or exceeds the following standards: ASTM E4, ISO7500-1, EN 100002-2, BS1610, DIN 51221. Starin measurement meets the following standards: ASTM E83, ISO 9513, BS 3846, EN10002-4. Safety: EN 50081-1, 580081-1, 73/23/EEC, EN 61010-1. Metals: ASTM E8, ISO 6892, ASTM E21, ISO 783, ISO 7438, ISO 14589, ASTM F606. Plastics/Composities; ASTM D638, ISO 6259, EN ISO 527-1, ISO 604, ASTM D695, ASTM D 3846, ISO 844, ISO 13968, ISO 9969. Geo-texiles: ASTM D3950, ASTM D 6775-02, BS EN ISO 10319, LBT 8521 |

ATI UTM-Pro

UNIVERSAL MATERIAL TESTING MACHINE

The ATI UTM-Pro is equipped with pre-loaded ball screws, heavy duty bearings, and robust guidance columns, ensuring exceptional stability and performance during testing. The design features aluminum covers with chamfered corners, facilitating convenient attachment of various accessories. A high-accuracy USA load cell is incorporated, enabling precise measurement of high loads, essential for rigorous testing requirements. The machine’s remote control system allows operators to monitor key parameters, including load, displacement, and speed. It also facilitates control over critical functions such as test initiation, termination, and zero clearing, enhancing operational efficiency. To ensure safety, the ATI UTM Pro features a fully enclosed safety shield that protects users during testing. Various gripping options, including pneumatic, hydraulic, and manual wedge-type grips, can be accommodated alongside bending fix- tures, allowing for versatile testing configurations within the chamber. An integrated limit indicator further enhances safety by illumi- nating upper and lower lights when the electronic limit is touched, preventing potential sensor overloads and equipment damage. This combination of advanced features makes the ATI UTM Pro a reliable and efficient solution for material testing in diverse applications.

LOAD FRAME AND LOAD WEIGHT SYSTEM

The ATI UTM Pro frames prioritize safety and flexibility, with robust crosshead guidance for stability and precision. Preloaded ball screws enable high-speed, low-noise operation with accurate position measurements. The four-column design ensures stiffness and structural integrity. Safety features include automatic stop, dual over-travel limits, and overload protection. The load system provides precise measurements (0.4% to 100% capacity) with 0.5% calibration accuracy and impact-resistant load cells, ensuring reliability and protection against overloads up to 300%.

TEST CONTROL FEATURES

The ATI UTM Pro features an advanced control system with three closed-loop controls for force, deformation, and displacement, enabling seamless transitions between modes. It utilizes 24-bit A/D converters for high-precision measurements and offers both pulse and analog output interfaces for controlling actuators. The system supports a USB interface for high transmission rates and real-time data processing. It includes a sensor self-recognition system and correction memory, allowing quick sensor replacement without recalibration. The user-friendly interface, with an LCD hand control box, is paired with key safety features like limit settings, overload protection, and an emergency stop function, ensuring reliable and secure operation for demanding testing applications.

SOFTWARE

The ATI UTM Pro software provides precise control for load, deformation, and displacement measurements. It offers an intuitive interface, supporting real-time closed-loop control and visualization of reference curves. Advanced graphical tools allow curve manipulation and detailed analysis of test data. The software includes automatic data processing, multilevel user access for security, and easy generation of commercial reports. Test data is stored in text files and can be transferred online for enhanced collaboration.

| MODEL | ATI UTM-Pro |

| Compliance Standards: | ASTM E4, ISO 7500-1, EN 10002-2, BS1610, DIN 51221 |

| Testing Load Accuracy: | 100 kN |

| Testing Load Range: | ± 0.5% |

| Testing Load Accuracy: | 0.4% ~ 100% FS |

| Load Resolution: | 1/500’000 FS |

| Deformation Measuring Range: | 0.2% ~ 100% FS |

| Deformation Accuracy: | ≤ + 0.5% |

| Deformation Resolution: | 1/500’000 FS of the maximum deformation |

| Test Control Mode: | Three Closed-Loop control, stress, strain and displacement |

| Displacement Accuracy: | Within ± 0.5% of the value |

| Displacement Resolution: | 0.04 μm |

| Constant Force Control Range: | 0.001 ~ 5% FS/s |

| Constant Force Control Range Accuracy: | When the rate is < 0.05% FS/s, it is within ± 2% of the set value. When the rate is ≥ 0.05% FS/s, it is within ± 0.5% of the set value |

| Constant Deformation Force Controll Range: | 0.005 ~ 5% FS/s |

| Constant Deformation Force Control Accuracy: | When the rate is < 0.05% FS/s, it is within ± 2% of the set value. When the rate is ≥ 0.05% FS/s, it is within ± 0.5% of the set value |

| Crosshead Speed Range: | 0.001 ~ 500 mm/min |

| Crosshead Speed Accuracy: | Within ± 0.5% of the value |

EASYDUR AURA

HIGH-LOAD UNIVERSAL MATERIAL TESTING MACHINE

EASYDUR AURA represents the latest generation of high-capacity, universal material testing machines, designed to meet the demands of modern laboratories. Featuring double recirculating ball guide systems for friction-free movement, it delivers exceptional sensitivity and precision across a wide range of testing applications. The system is fully controlled by advanced computer software, operating seamlessly on Windows 10. EASYDUR AURA integrates the original Affri closed-loop system and bidirectional load cells, enabling accurate testing of materials such as traction, compression, bending, cyclic behavior, elasticity, and creep. It is ideal for testing diverse materials including springs, metals, plastics, fabrics, composites, and more. The machine supports both single and repetitive measurements, with data that can be stored across multiple cycles and linked to product and customer codes for traceability. Additionally, it includes a Q reader for automatic product recognition, enhancing testing efficiency. EASYDUR AURA can be easily connected to an Ethernet network for continuous remote support, calibration, and data transmission. Optional multi-cell configurations are pre-installed, ensuring the system is always ready for immediate use and versatile testing capabilities.

EASYDUR AURA MAIN FEATURES

- Triple Load Cells: Three pre-installed, calibrated load cells for immediate use.

- High Precision: 1ms sensitivity and 100,000 divisions for accurate measurements.

- User-Friendly Software: Intuitive, no training required, with fully guided test procedures.

- Customizable Reports: Filterable, easy-to-manage data sheets.

- Versatile Testing: Ideal for springs and various materials, with high-capacity data storage.

- Wide Accessories Selection: Customizable options for different tests.

- Intuitive Touch Panel: Easy-to-use interface with high-definition display.

- Safety Compliant: CE-certified with controlled closing and anti-break-in features.

- Remote Support: Multilingual software with Ethernet connectivity for remote assistance.

- High-Precision Measurements: 0.001mm resolution in extension and flexible strain gauge options.

| MODEL | AURA 10 | AURA 30 | AURA 60 | AURA 100 |

|---|---|---|---|---|

| Capacity KN | 100 | 300 | 600 | 1000 |

| Division N | 3 | 10 | 20 | 30 |

| MAX speed test mm/sec | 350 | 300 | 250 | 250 |

| MIN speed test mm/sec | 0.05 | 0.05 | 0.05 | 0.05 |

| Height capacity | 1000 | 1000 | 1200 | 1600 |

| Resolution | 0.03 | 0.03 | 0.03 | 0.03 |

EASYDUR 3MZ

MEDIUM-LOAD UNIVERSAL MATERIAL TESTING MACHINE

EASYDUR 3MZ is a next-generation universal material testing machine with medium load capacity, offering high sensitivity and precision. It features friction-free sliding with double ball bearing guides and is fully operated via a Windows 10 computer. The machine includes the original Affri “Closed-Loop” system with bidirectional load cells. It supports various tests such as traction, compression, bending, and cyclic on materials like springs, metals, plastics, and fabrics. Measurements can be stored and associated with product and customer codes. The system offers scanning with a Q reader for product recognition and supports Ethernet connectivity for continuous assistance, calibration, and data transfer. Pre-inserted multi-cells are available for immediate use.

EASYDUR 3MZ MAIN FEATURES

- Three Load Cells: Pre-calibrated, ready-to-use load cells with different capacities, no assembly needed.

- High Precision: 1ms sensitivity and 100,000 divisions for accurate measurements.

- User-Friendly Software: Intuitive, no training required, with guided testing and customizable data reporting.

- Data Storage: Stores test data in a high-capacity database for repetitive cycles.

- Custom Accessories: Wide range of test-specific, customizable accessories.

- HD Touch Panel: Easy-to-use controls via a high-definition touch screen.

- Safety Features: Controlled closing and anti-break-in, compliant with CE standards.

- Network Connectivity: Multilingual software with Ethernet for remote assistance and data transfer.

- Precise Measurement: 0.001mm extension precision, with contact and optical strain gauges.

| MODEL | 3MZ 1 | 3MZ 2,5 | 3MZ 5 |

|---|---|---|---|

| Capacity KN | 10 | 25 | 50 |

| MIN division N | 0.33 | 1.23 | 1.7 |

| Useful height | 800 mm | ||

| MIN division | 0.01 mm | ||

| Other capacity | 10, 30, 50, 100, 300, 500, 750, 1000, 1500, 2000, 3000, 5000 N | ||

| MIN division | 1 / 30.000 | ||

| Power supply | 220 V , 50/60 Hz , 200 VA | ||

EASYDUR DYNO

MEDIUM-LOAD UNIVERSAL MATERIAL TESTING MACHINE

EASYDUR Dyno is a next-generation medium-load universal material testing machine with double ball bearing guides, friction-free sliding, and high sensitivity and precision. It is fully computer-controlled in a Windows 10 environment, featuring the original Affri closed-loop system with bidirectional load cells. It supports tests such as traction, compression, bending, cyclic, elasticity, and creep on various materials, including springs, metals, plastics, and fabrics. The machine allows for both single and repetitive measurements, which can be stored and linked with product and customer codes. It also includes Q reader scanning for product recognition, Ethernet connectivity for continuous assistance and calibration, and pre-inserted multi-cells ready for immediate use.

EASYDUR DYNO MAIN FEATURES

- Three Load Cells: Pre-calibrated and ready for use, eliminating assembly.

- High Precision: 1ms sensitivity and 100,000 divisions.

- User-Friendly Software: Intuitive, no training required, with automated test procedures.

- Data Management: Stores and processes data for easy report generation.

- Custom Accessories: Tailored for specific tests.

- HD Touch Panel: Easy-to-use interface.

- Safety: Compliant with CE standards.

- Multilingual & Ethernet-Connected: Remote support and data transfer.

- Precise Measurement: 0.001mm extension accuracy with contact and optical strain gauges.

| MODEL | DYNO 10 | DYNO 15 | DYNO 20 | DYNO 30 | DYNO 40 |

|---|---|---|---|---|---|

| Capacity KN | 1 KN | 1.5 KN | 2 KN | 3 KN | 4 KN |

| MIN division N | 0.4 N | 0.06 N | 0.08 N | 0.12 N | 0.16 N |

| Useful height | 300 mm | ||||

| MIN division | 0.01 mm | ||||

| Inter-axis columns | 215 mm | ||||

| Plates diameter | 100 mm | ||||

| Power supply | 220 V , 50/60 Hz , 200 VA | ||||