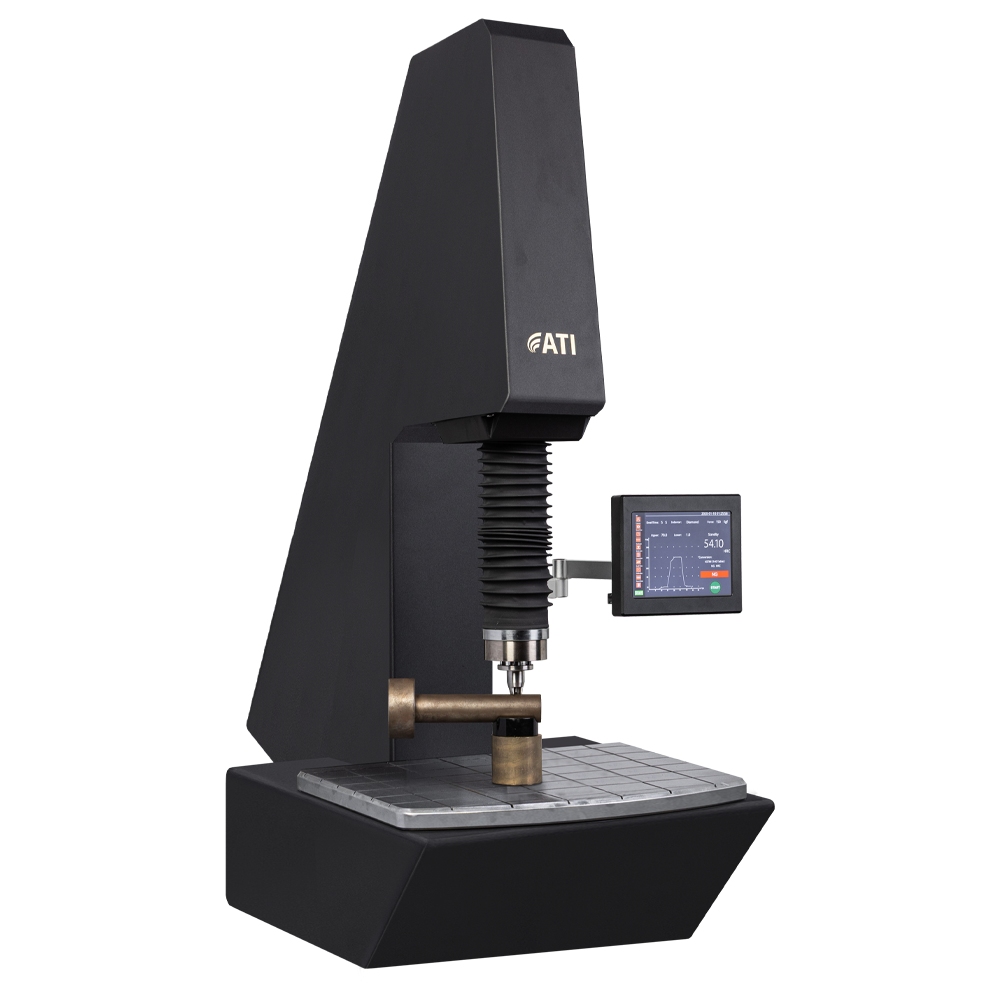

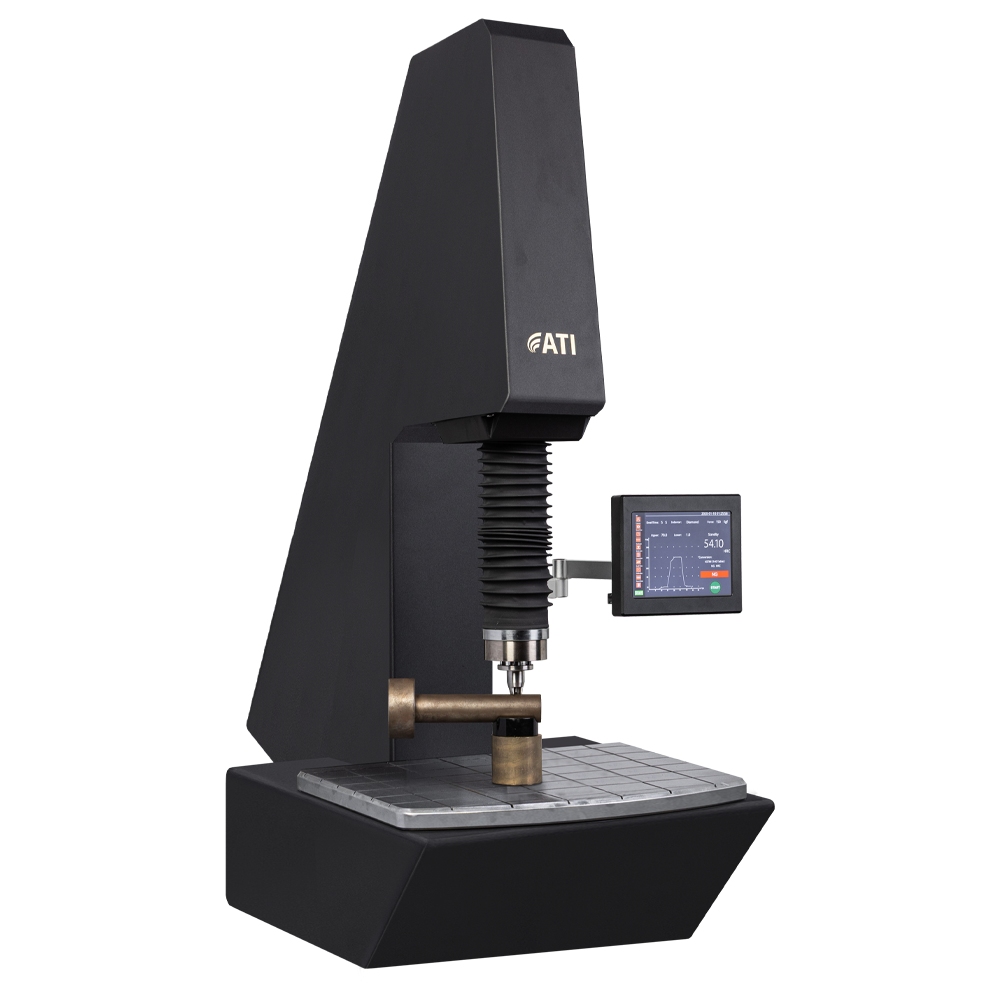

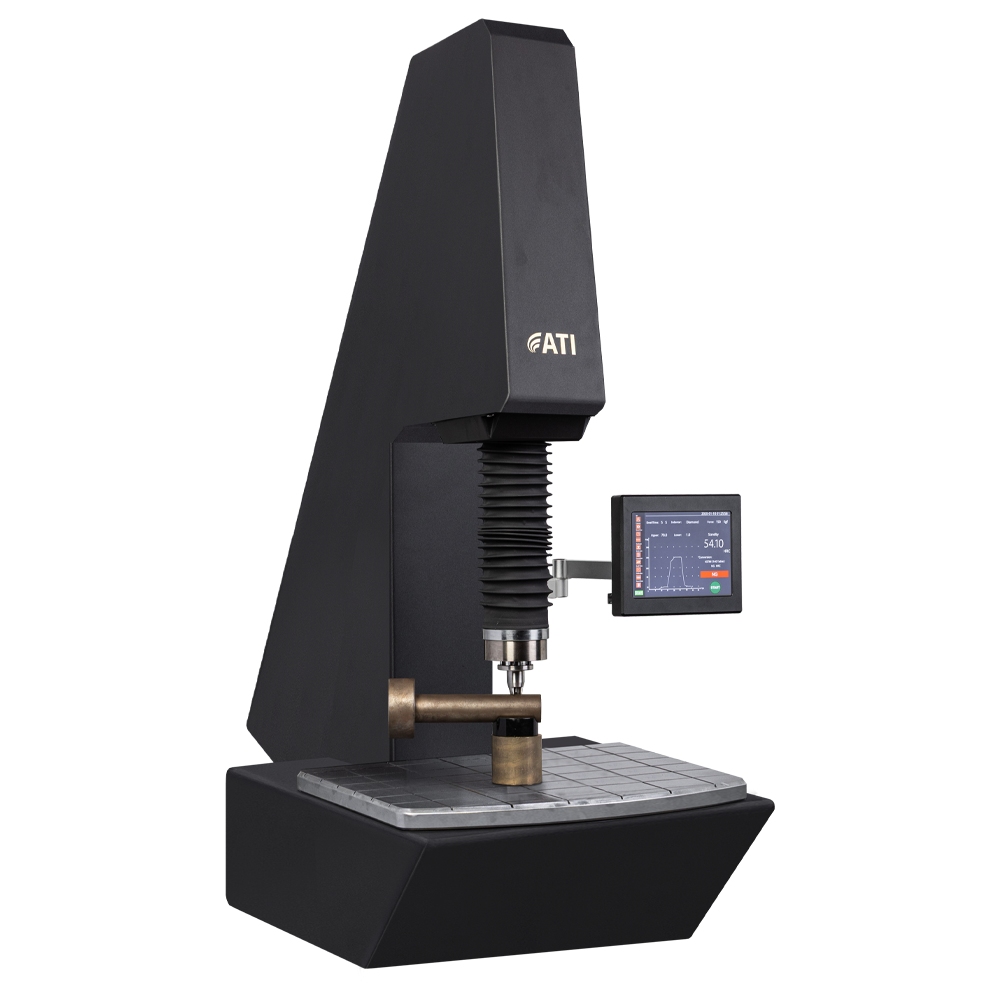

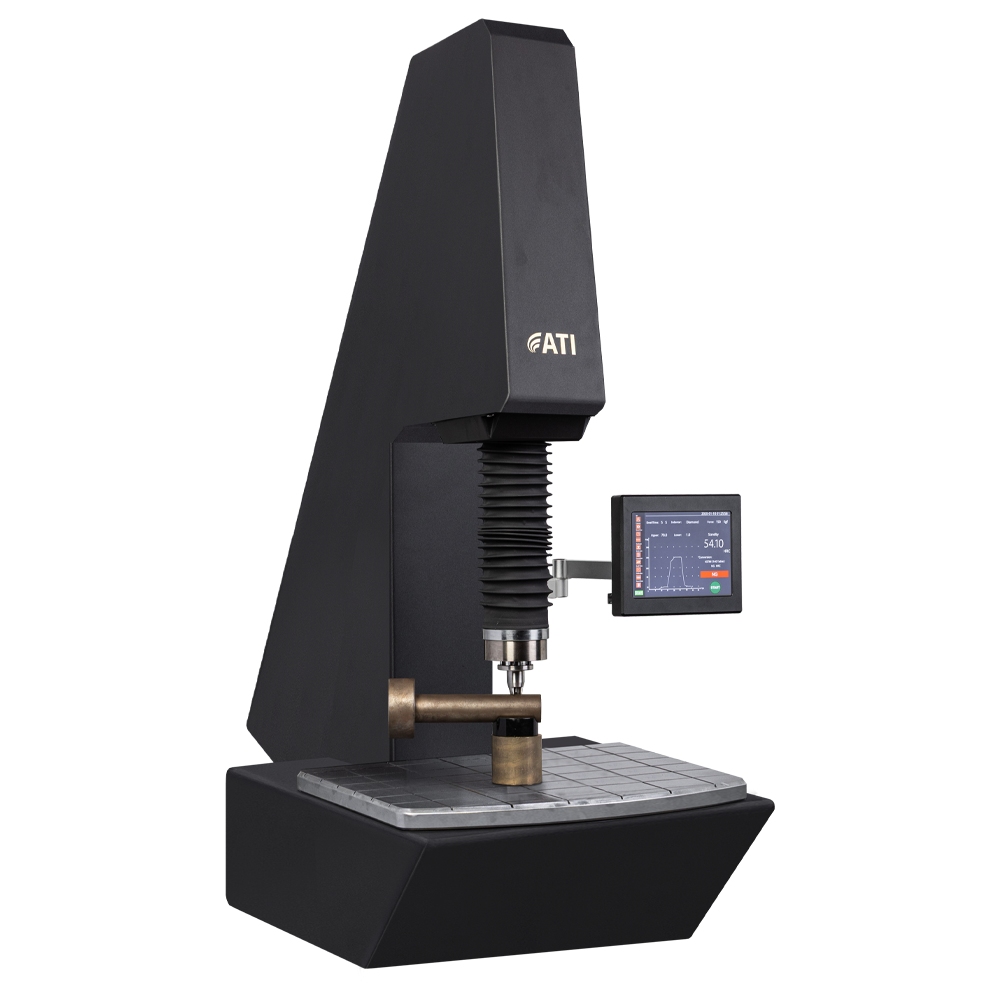

ATI HTR

Fully automatic Rockwell hardness tester with motorized vertical stroke of the measuring head

ATI HTR is a fully automatic advanced Rockwell hardness tester designed to accurately measure the hardness of ferrous, non-ferrous metals, and non-metal materials.

Test force closed-loop control system ensures precise automatic tracking and testing, eliminating any poten- tial errors caused by deformation of the frame or workpiece. The measuring head offers automatic vertical movement, allowing for quick and secure clamping of workpieces without manual application of preliminary test force. Our advanced test force closed-loop control system ensures precise automatic tracking and testing, eliminating any potential errors caused by deformation of the frame or workpiece. This system is designed to optimize efficiency and accuracy in testing processes, featuring a high-precision optical grating displacement measuring system.

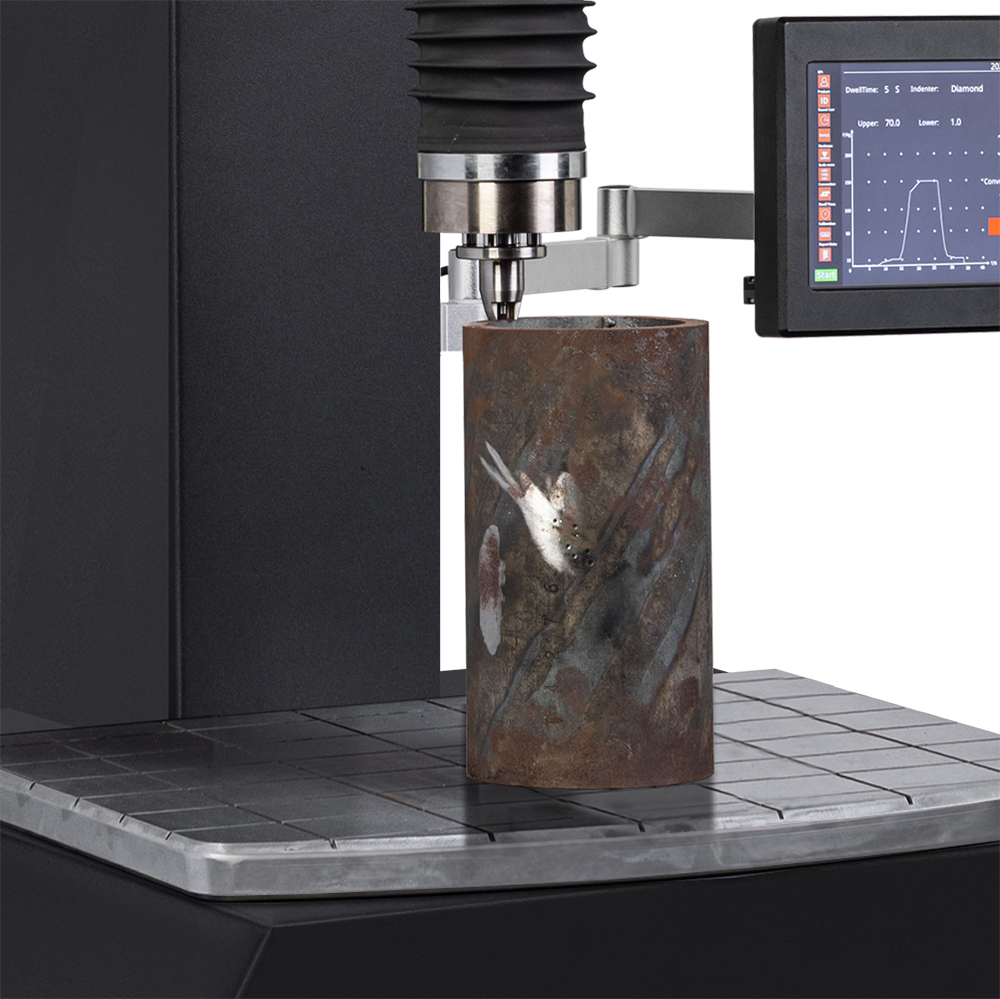

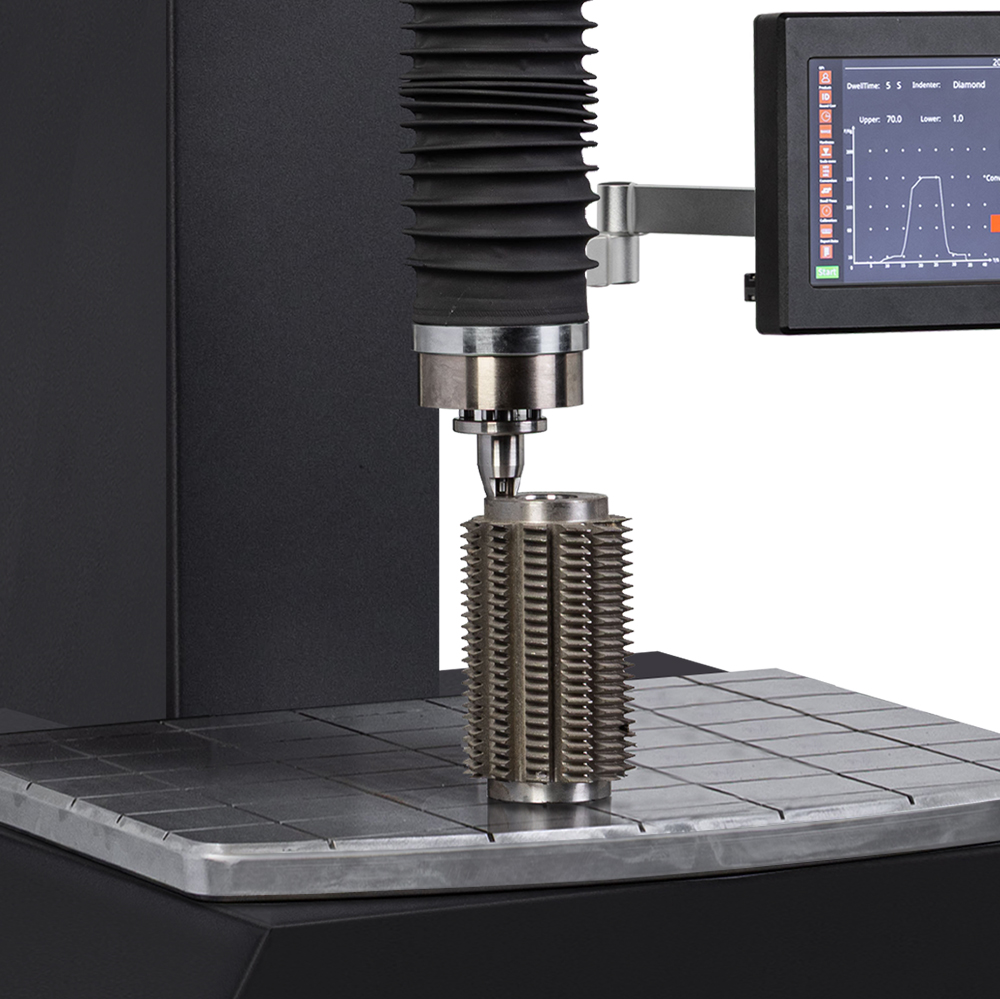

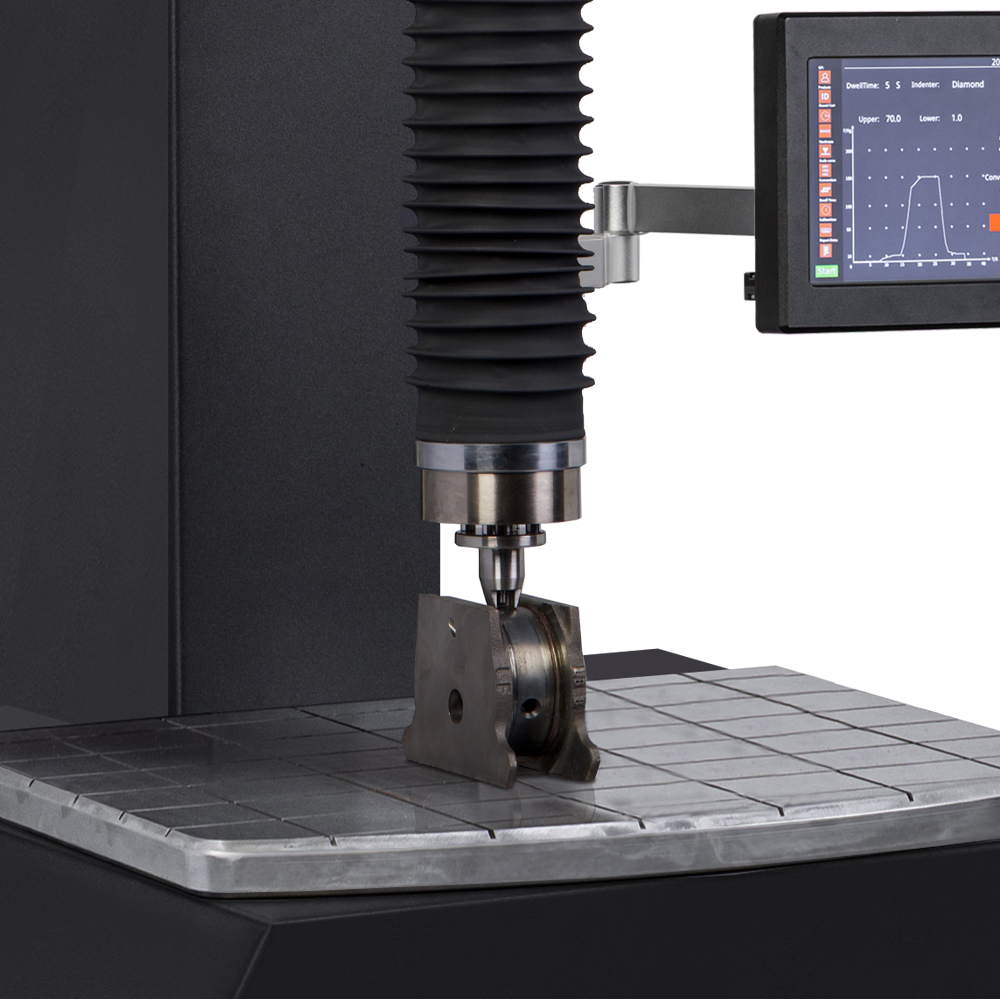

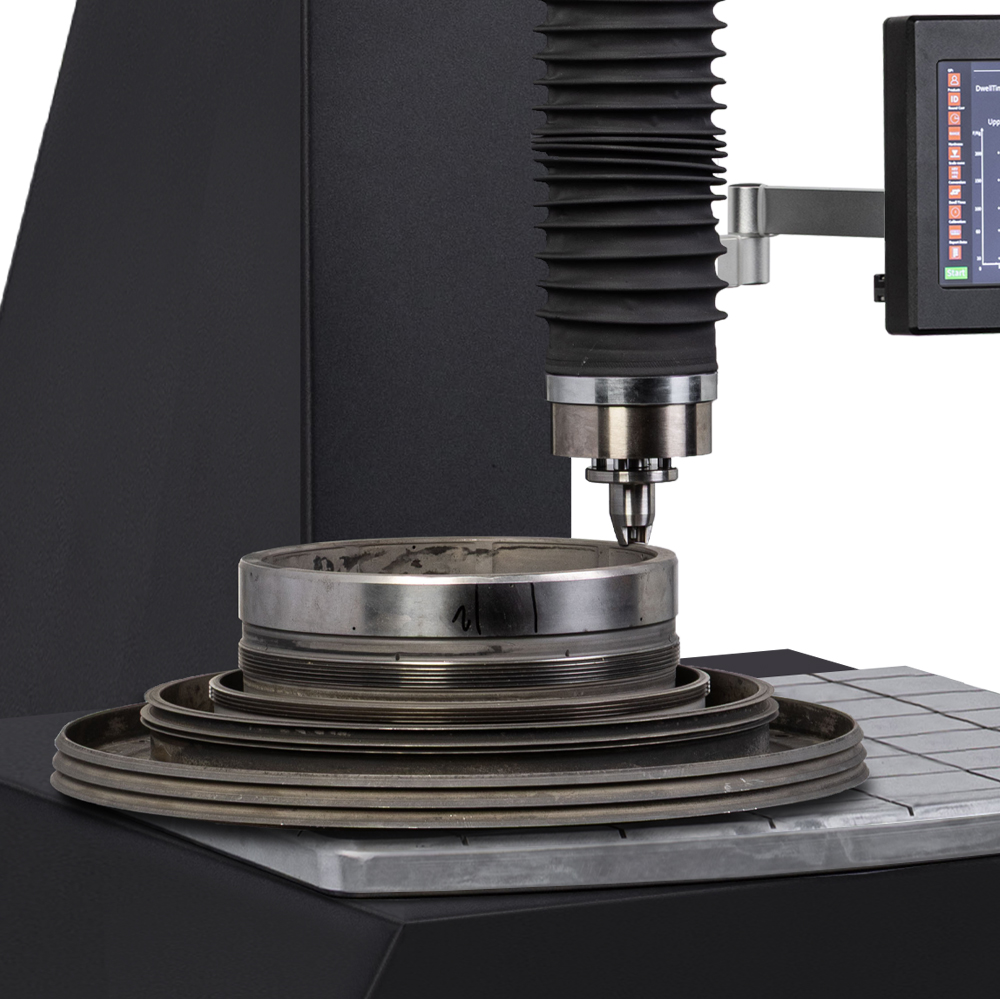

APPLICATIONS

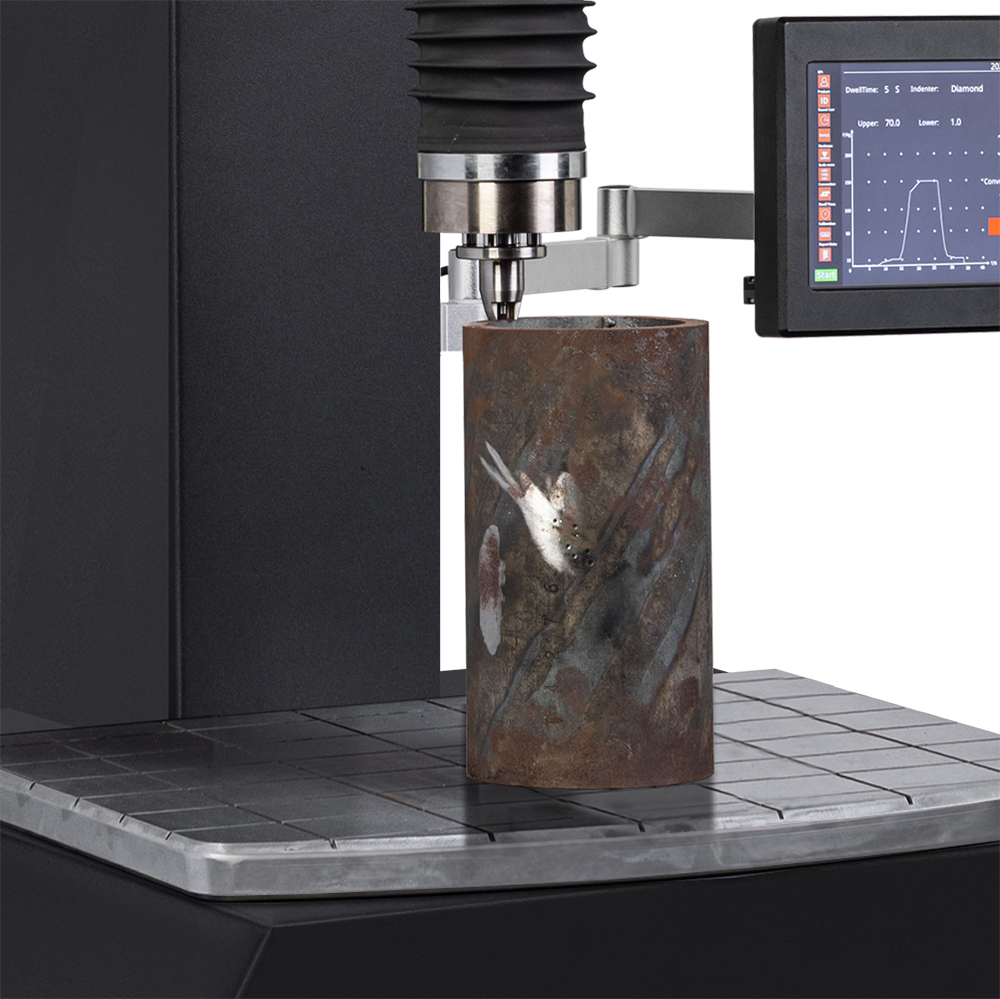

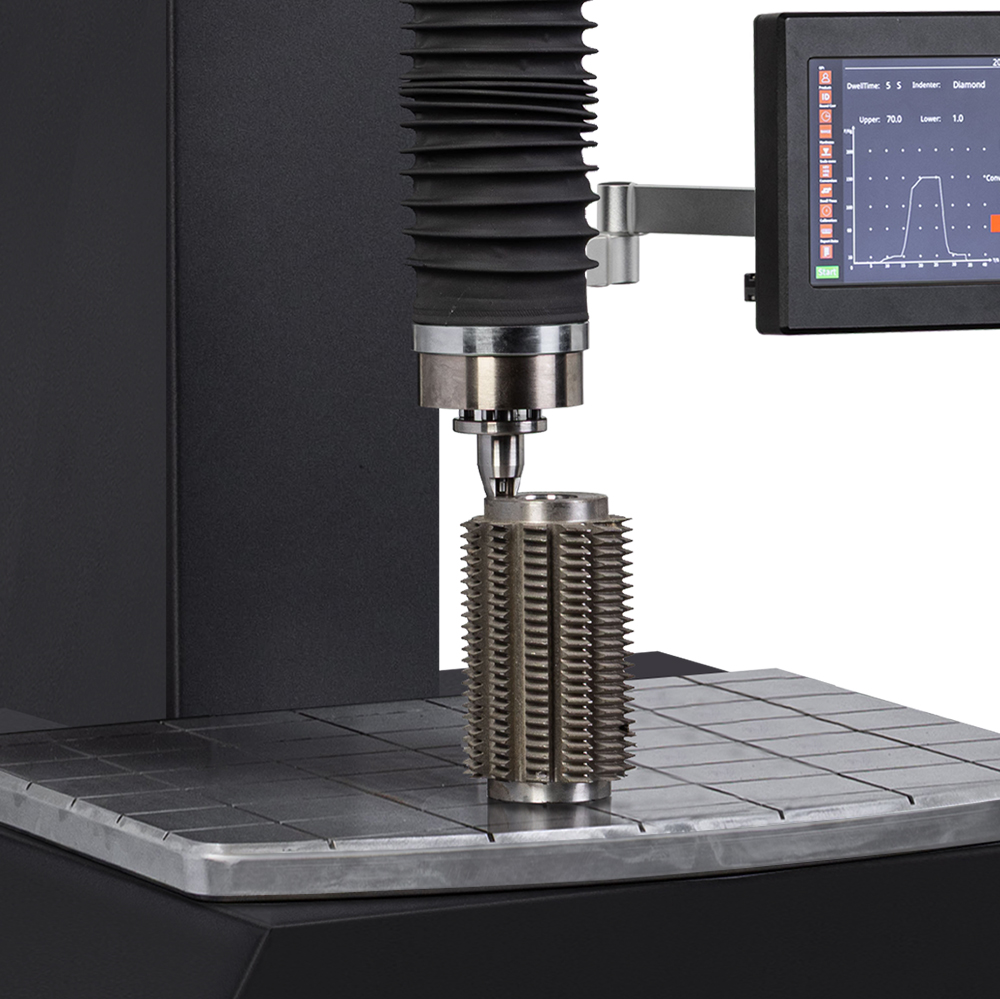

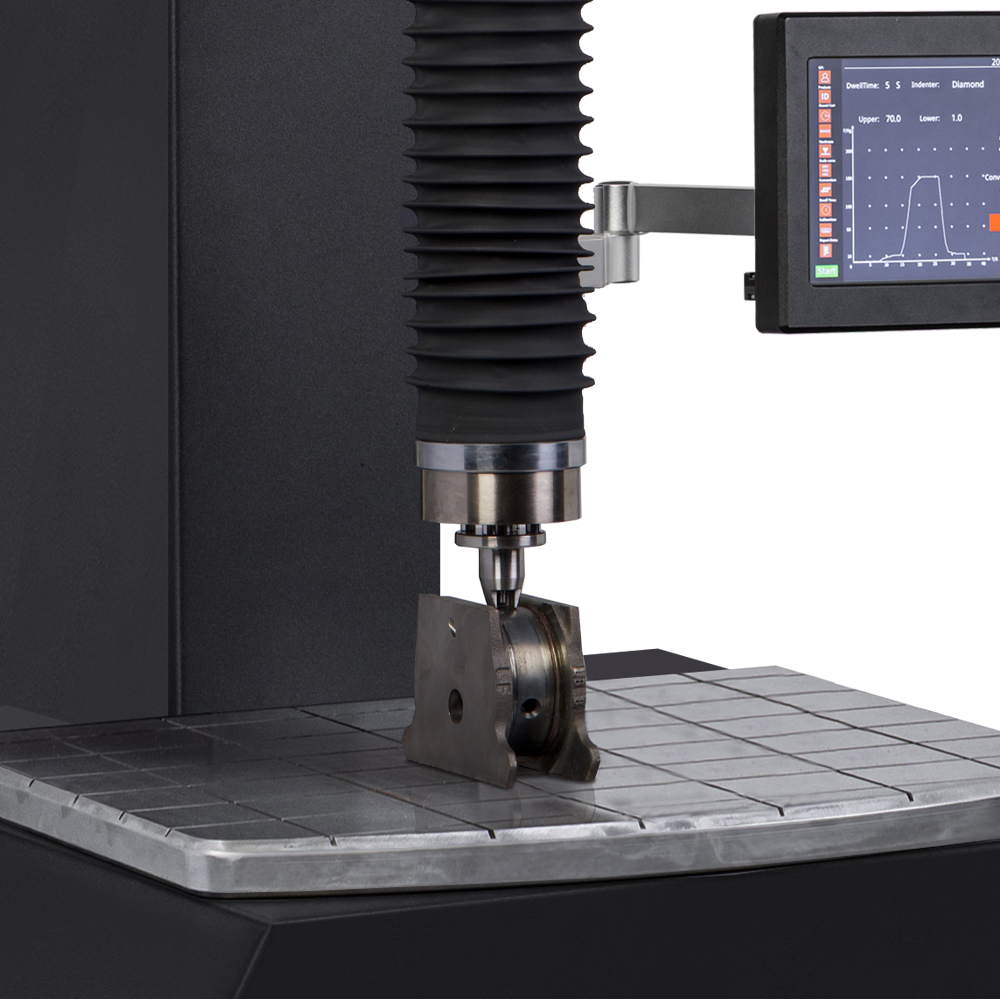

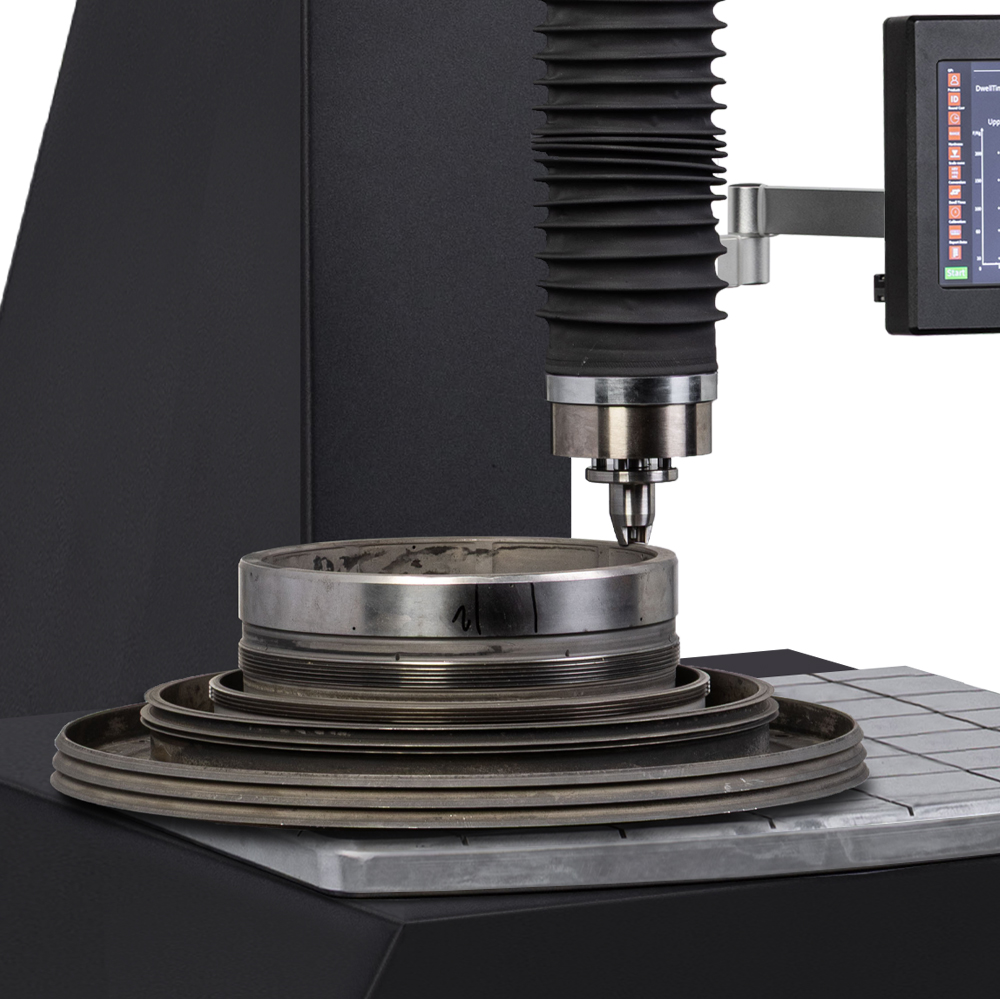

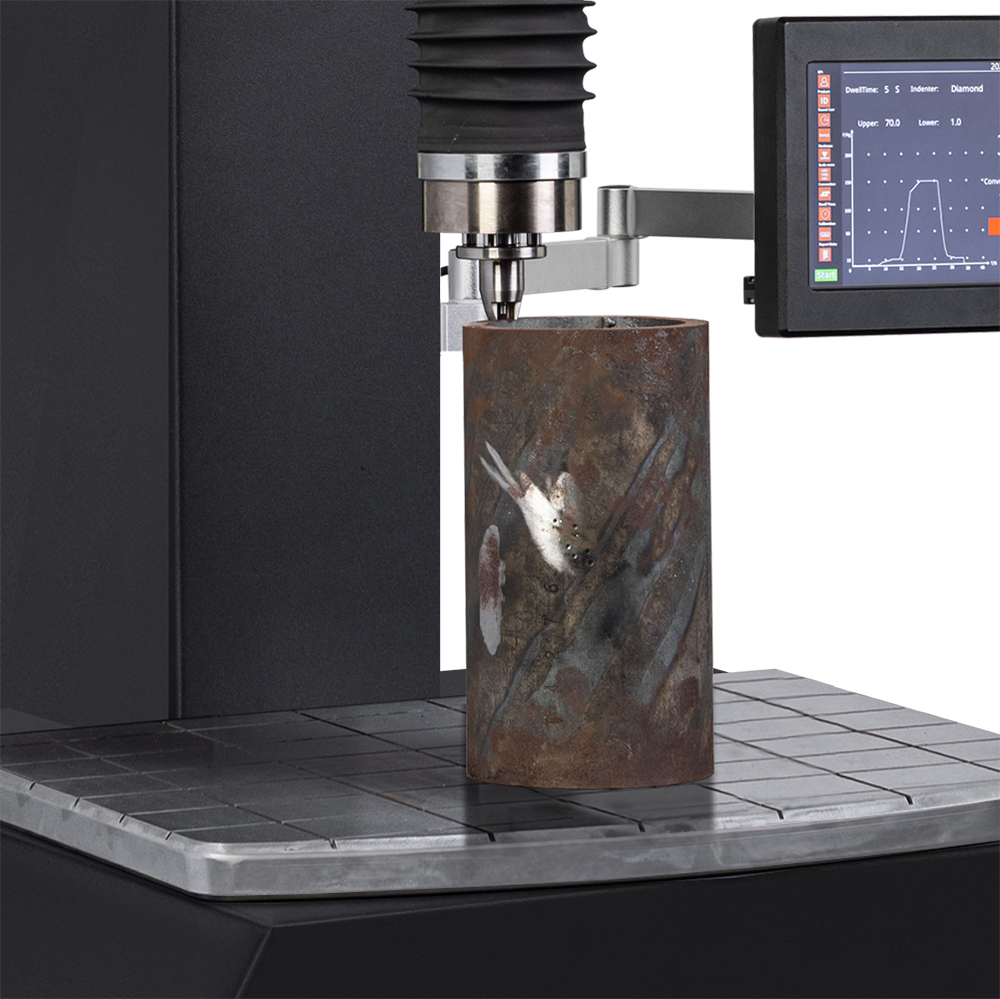

ATI HTR is a highly accurate hardness tester used for testing heat-treated materials like those that have undergone hardening or tempering. Known for its reliability and precision, it performs consistently on both flat and curved surfaces, making it suitable for complex geometries. Ideal for industrial applications and quality control, the ATI HTR ensures materials meet required hardness standards. Its robust design and versatile features make it an essential tool in metalworking, manufacturing, and materials testing.

ONE BUTTON MEASUREMENT

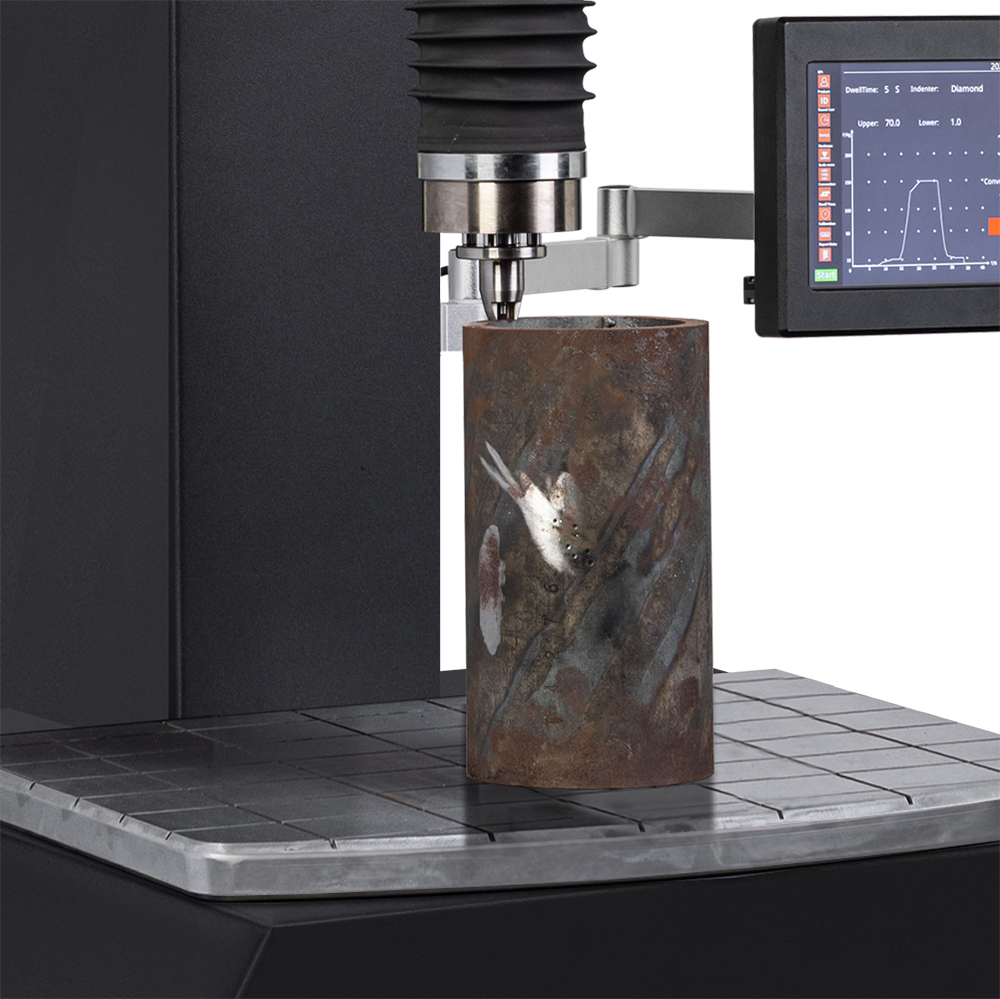

MOTORIZED VERTICAL STROKE OF THE MEASURING HEAD

The measuring head has a motorized vertical stroke of 300 mm. Once the test cycle has started, the measuring head recognizes the distance between the piece and the indenter and automatically goes down until it comes into contact with the surface to be measured. The head will maintain contact with the sample surface for the entire test cycle, without ever losing contact, ensuring a perfect and absolute measurement in any test condition. Contact is ensured by the piece pressing action exerted by the head, preventing any movement of the sample and ensuring perfect stability during the entire hardness test. With ATI HTR hardness measurements become easy and fast. It is the solution for hardness tests on components of different thickness, size and shape, allowing measurements to be taken without any prior adjustment.

JOYSTICK CONTROLLED MEASURING HEAD

ATI HTR is equipped with a joystick through which the operator can easily control the movement of the measuring head and have full control over it. Simply move the joystick up or down to raise or lower the measuring head respectively.

ATI HTR

Fully automatic Rockwell hardness tester with motorized vertical stroke of the head

ATI HTR is a fully automatic advanced Rockwell hardness tester designed to accurately measure the hardness of ferrous, non-ferrous metals, and non-metal materials.

Test force closed-loop control system ensures precise automatic tracking and testing, eliminating any poten- tial errors caused by deformation of the frame or workpiece. The measuring head offers automatic vertical movement, allowing for quick and secure clamping of workpieces without manual application of preliminary test force. Our advanced test force closed-loop control system ensures precise automatic tracking and testing, eliminating any potential errors caused by deformation of the frame or workpiece. This system is designed to optimize efficiency and accuracy in testing processes, featuring a high-precision optical grating displacement measuring system.

APPLICATIONS

ATI HTR is a highly accurate hardness tester used for testing heat-treated materials like those that have undergone hardening or tempering. Known for its reliability and precision, it performs consistently on both flat and curved surfaces, making it suitable for complex geometries. Ideal for industrial applications and quality control, the ATI HTR ensures materials meet required hardness standards. Its robust design and versatile features make it an essential tool in metalworking, manufacturing, and materials testing.

ONE BUTTON MEASUREMENT

MOTORIZED VERTICAL STROKE

The measuring head has a motorized vertical stroke of 300 mm. Once the test cycle has started, the measuring head recognizes the distance between the piece and the indenter and automatically goes down until it comes into contact with the surface to be measured. The head will maintain contact with the sample surface for the entire test cycle, without ever losing contact, ensuring a perfect and absolute measurement in any test condition. Contact is ensured by the piece pressing action exerted by the head, preventing any movement of the sample and ensuring perfect stability during the entire hardness test. With ATI HTR hardness measurements become easy and fast. It is the solution for hardness tests on components of different thickness, size and shape, allowing measurements to be taken without any prior adjustment.

JOYSTICK CONTROLLED MEASURING HEAD

ATI HTR is equipped with a joystick through which the operator can easily control the movement of the measuring head and have full control over it. Simply move the joystick up or down to raise or lower the measuring head respectively.

X-Y AUTOMATIC and MOTORIZED WORKBENCH

The X-Y automatic and motorized table, with dimensions of 350 mm x 250 mm, can support samples up to 100 kg. This X-Y workbench has an X-axis travel of 200 mm, a Y-axis travel of 90 mm, and a minimum step size of 0.01 mm. It also features a high-resolution overview camera for precise edge identification and accurate detection of the origin point.

| Model: | ATI HTR |

| Compliance standards: | ISO 6508-2, ASTM E18 and GB/T 230.2 |

| Hardness scales | HRA, HRB, HRC, HRD,HRE,HRF, HRG,HRH, HRK, HRL, HRM, HRP, HRR, HRS, HRV, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HR15W, HR30W, HR45W, HR15X, HR30X, HR45X, HR15Y, HR30Y, HR45Y |

| Pre-load: | 3 Kg (29.4 N), 10 Kg (98.1 N) |

| Test force: | Superficial Rockwell: 15Kg (147.1N), 30Kg (294.2N), 45Kg (441.3N) – Rockwell: 60Kg (588.4N), 100Kg (980.7N), 150Kg (1471N) |

| Test force accuracy: | ±1% |

| Test force accuracy: | Superficial Rockwell: 71 |

| Indenter: | Rockwell diamond indenter, Ø1/16” ball indenter |

| Dwell time: | Initial test force: 0.1-50 sec – Total test force: 0.1-50 sec |

| Data output: | USB interface, RS 232 interface and in-built bluetooth interface |

| Height capacity: | 300 mm (ordinary workbench) and 180mm (X-Y automatic workbench) (customizable) |

| Depth capacity: | 200 mm |

| Vertical stroke of measuring head: | 300 mm |

| X-Y table dimensions: | 400 x 330 mm |

| Max weight of sample: | 2000 Kg |

| Power supply: | 220V / 110V , 50 Hz / 60 Hz |

| Dimensions: | 669 x 477 x 877 mm – Weight: 130 Kg |