Universal Spring Testing Machines

Discover a complete range of universal spring testing machines, perfect for any application, industry, and material type.

UNIVERSAL SPRING TESTING MACHINES FOR ALL NEEDS AND APPLICATIONS

Universal Springs Testing Machines are essential components in a wide range of industries, including automotive, electronics, and medical sectors. To ensure their functionality and performance, precise testing is crucial. Universal spring testing machines are designed to meet these needs by offering advanced solutions for the characterization and quality control of springs of all types. These versatile machines provide accurate compression and tension testing, essential for verifying spring properties and material integrity.

Load Capacity and Precision

- Wide Load Capacity Range: Available models can handle load capacities from 10 N up to 3,000 kN, covering the testing needs of various industries.

- High Resolution: With a resolution of up to 200,000 divisions, these machines provide precise and accurate measurements for spring testing, ensuring reliable results.

Versatility and Adaptability

- Versatile Testing Capabilities: These machines are designed not only for compression and tension testing of springs but can also accommodate other mechanical tests across different materials with the appropriate accessories.

- Interchangeable Testing Fixtures: Easily swap compression plates with hooks and grips for tension testing, allowing for seamless testing of a wide range of spring types, including ground and ungrouded springs.

- Adaptability to Future Needs: The “all-in-one” design allows these machines to meet current industry requirements while being adaptable to future challenges, such as new projects, differentiation needs, and compliance with updated standards.

Special Applications and Customization

- Customization for Special Applications: The machines can be configured to test special spring types, including oval or rectangular section springs, shaped wire or strip springs, conical and biconical springs, as well as springs with non-constant external diameters (e.g., MacPherson struts).

- Multi-Cell and Multi-Channel Testing: Advanced systems enable lateral load detection during testing, especially for complex applications that require multi-cell or multi-channel analysis.

Dynamic Testing and Automation

- Dynamic Testing Capabilities: Beyond static tests, these machines are equipped to perform dynamic testing, providing essential data for high-performance applications.

- Automated Quality Control: Automated testing of 100% of spring production ensures consistent quality and reliability throughout manufacturing processes.

Advanced Features for Quality Control

- Advanced Vision Systems: Integrated vision systems enable precise visual inspection of springs during testing, enhancing the quality control process.

- User-Friendly Software: Proprietary testing software simplifies program creation, rapid mathematical calculations, and real-time data analysis, including generating comprehensive graphs and reports for thorough documentation.

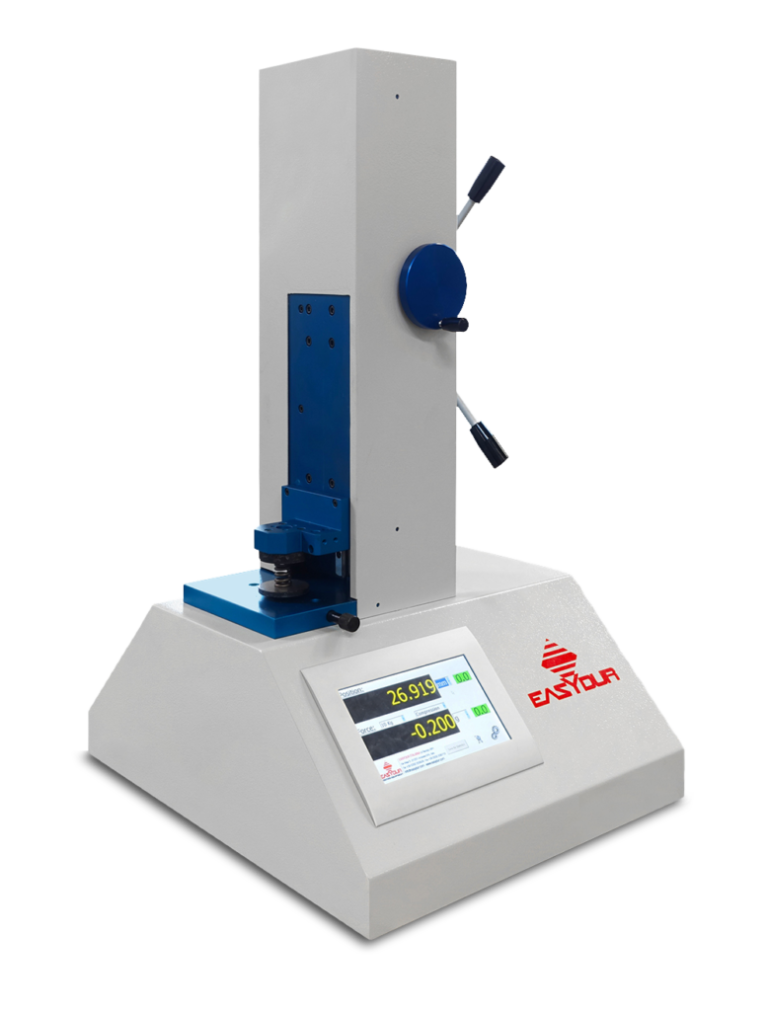

EASYDUR 2C

SPRING TESTING MACHINE

EASYDUR 2C Spring Machine is a next-generation manual testing instrument for medium-load springs, featuring double recirculating ball guides for frictionless, precise movement. It uses bidirectional load cells for accurate measurements and supports both positive and negative twist at multiple positions. The device includes self-zero recognition and product scanning with a Q reader. It also offers Ethernet connectivity for remote assistance, calibration, and data transmission, with pre-inserted multi-cells ready for immediate use.

MAIN FEATURES

- Load cells: The 2C model can install 3 pre-calibrated load cells with varying capacities, eliminating assembly needs.

- User interface: High-definition, intuitive touch panel controls with keys.

- Multilingual software: Connects to Ethernet for remote assistance and data transfer.

- Precision: Absolute extension measurement with 0.001 mm resolution.

- High sensitivity: 1ms reactive measurement, 100,000 divisions, and 0.1° accuracy.

- Optional software: For creating displacement/load reports and diagrams.

- Customizable accessories: Wide range of accessories for different tests, detailed in the datasheet.

| MODEL | 2C10 | 2C15 | 2C20 | 2C30 | 2C40 |

|---|---|---|---|---|---|

| MAX Capacity | 1 KN | 1.5 KN | 2 KN | 3 KN | 4 KN |

| MIN division | 0.04 N | 0.06 N | 0.08 N | 0.12 N | 0.16 N |

| Usable height | 300 mm | ||||

| MIN division | 0.01 mm | ||||

| Inter-asxis columns | 215 mm | ||||

| Plates diameter | 100 mm | ||||

| Power supply | 220 V , 50/60 Hz , 200 VA | ||||

EASYDUR PC

SPRING TESTING MACHINE

EASYDUR PC Spring Machine is a next-generation manual spring testing instrument for medium loads. It features double recirculating ball guides for frictionless, precise movement and bidirectional load cells. The device supports both positive and negative twists at multiple positions and loops, with self-zero recognition and product scanning via Q reader. It offers Ethernet connectivity for continuous assistance, calibration, and data transmission, with pre-inserted multi-cells ready for immediate use.

MAIN FEATURES

- Load cells: Ability to install 3 pre-calibrated load cells with varying capacities, ready for use without assembly.

- User interface: Intuitive, high-definition touch panel with keys.

- Software: Multilingual, Ethernet-enabled for remote assistance and data transfer.

- Precision: Absolute extension measurement with 0.001 mm resolution.

- High sensitivity: 1 millisecond reactive measurement and 100,000 divisions.

- Optional software: For creating displacement/load reports and diagrams.

- Custom accessories: Wide selection of accessories for different tests, detailed in the datasheet.

| MODEL | PC3 | PC5 | PC10 | PC20th> | PC50 |

|---|---|---|---|---|---|

| MAX Capacity | 30 KN | 50 KN | 100 KN | 200 KN | 500 KN |

| MIN division | 0.0012 N | 0.002 N | 0.004 N | 0.008 N | 0.020 N |

| Usable height | 197 mm | ||||

| MIN division | 0.01 mm | ||||

| Plate diameter | 50 mm | ||||

| Power supply | 220 V , 50/60 Hz , 200 VA | ||||