EASYDUR EASY FLAG

Radial Brinell Hardness Tester for Forges, Heat Treatments and Steel Factories

EASYDUR EASY FLAG is radial Brinell hardness tester for forges, heat treatments and steel factories with built-in milling tool for the sample surface preparation before the indentation. For huge samples . Test Loads from 10 kg to 3000 kg.

- TEST LOADS from 10 kgf to 3000 kgf (98.07 to 29421 N)

- BRINELL HBWT ISO 6506 / ASTM E-10 HBW 1/10 – HBW 1/30 – HBW 2.5/15.625 – HBW 2.5/31.25 – HBW 2.5/62.5 – 2.5/187.5 – 5/25 – 5/62,5 – 5/125 – 5/250 – 5/750 – 10/100 – 10/250 – 10/500 – 10/1000 – 10/1500 – 10/3000

- Rockwell and superficial Rockwell ISO 6508 / ASTM E-18 HRA – HRB – HRC – HRD – HRF – HRG – HRL – HRM – HRR / HRN – HRT

EASYDUR EASY FLAG

Radial Brinell Hardness Tester for Forges, Heat Treatments and Steel Factories

EASYDUR EASY FLAG is radial Brinell hardness tester for forges, heat treatments and steel factories with built-in milling tool for the sample surface preparation before the indentation. For huge samples . Test Loads from 10 kg to 3000 kg.

- TEST LOADS from 10 kgf to 3000 kgf (98.07 to 29421 N)

- BRINELL HBWT ISO 6506 / ASTM E-10 HBW 1/10 – HBW 1/30 – HBW 2.5/15.625 – HBW 2.5/31.25 – HBW 2.5/62.5 – 2.5/187.5 – 5/25 – 5/62,5 – 5/125 – 5/250 – 5/750 – 10/100 – 10/250 – 10/500 – 10/1000 – 10/1500 – 10/3000

- Rockwell and superficial Rockwell ISO 6508 / ASTM E-18 HRA – HRB – HRC – HRD – HRF – HRG – HRL – HRM – HRR / HRN – HRT

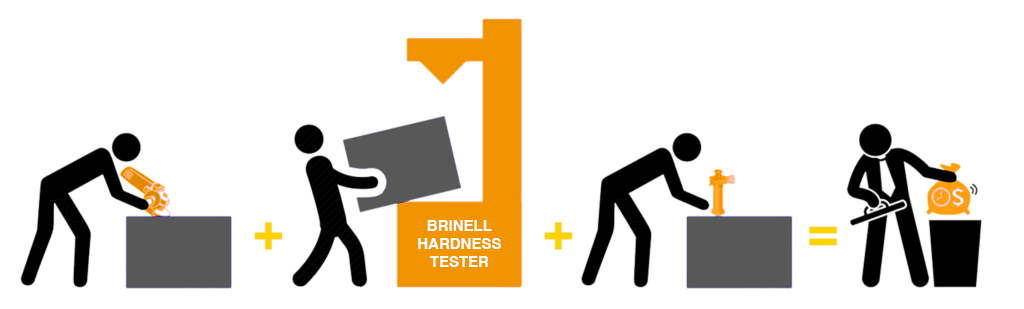

CONVENTIONAL BRINELL TESTS

The traditional Brinell hardness test, widely used in forges and steel plants, involves testing large components that have been pretreated to eliminate rust, scale, and other surface contaminants. Typically, a grinding wheel is employed to manually polish the surface, though this technique presents several challenges, such as the risk of heating the material, removing an unknown amount of material, generating fine metal dust, and consuming considerable amounts of time and labor.

Once the sample is properly prepared, it is placed under a Brinell hardness tester, which can be either manual or automated. The tester applies a specific load to a hard steel or carbide ball, which leaves an indentation on the surface. The depth and diameter of the indentation are then measured, often using a microscope, to determine the material’s hardness value. This process can be tedious and requires precise measurements to ensure the accuracy of the results.

CONVENTIONAL BRINELL TESTS

The traditional Brinell hardness test, widely used in forges and steel plants, involves testing large components that have been pretreated to eliminate rust, scale, and other surface contaminants. Typically, a grinding wheel is employed to manually polish the surface, though this technique presents several challenges, such as the risk of heating the material, removing an unknown amount of material, generating fine metal dust, and consuming considerable amounts of time and labor.

Once the sample is properly prepared, it is placed under a Brinell hardness tester, which can be either manual or automated. The tester applies a specific load to a hard steel or carbide ball, which leaves an indentation on the surface. The depth and diameter of the indentation are then measured, often using a microscope, to determine the material’s hardness value. This process can be tedious and requires precise measurements to ensure the accuracy of the results.

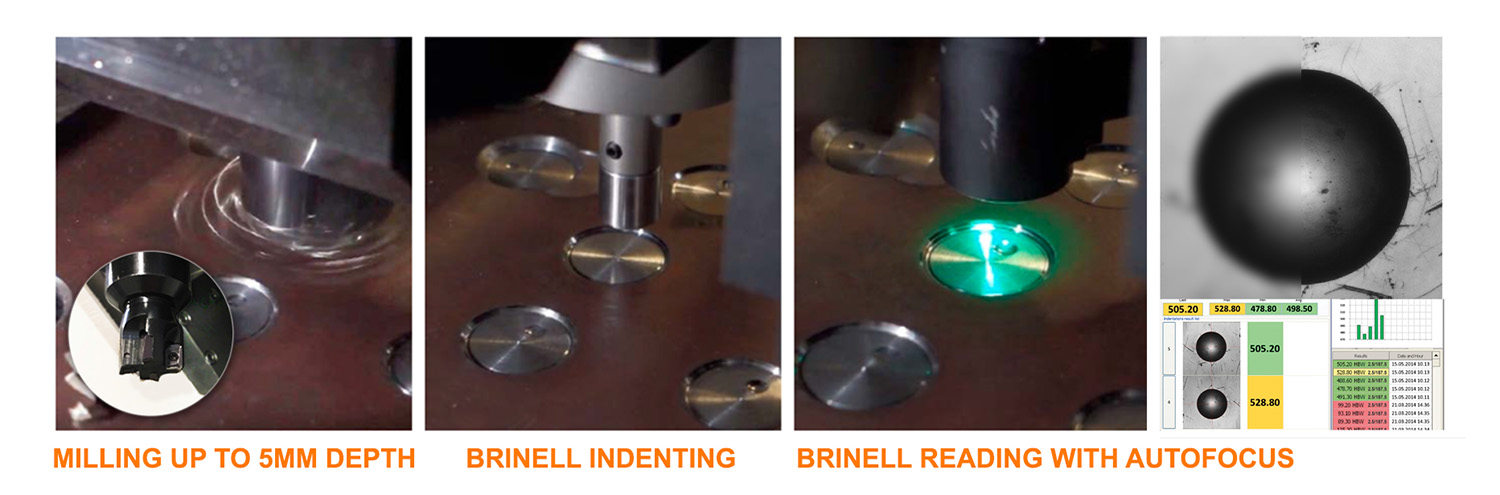

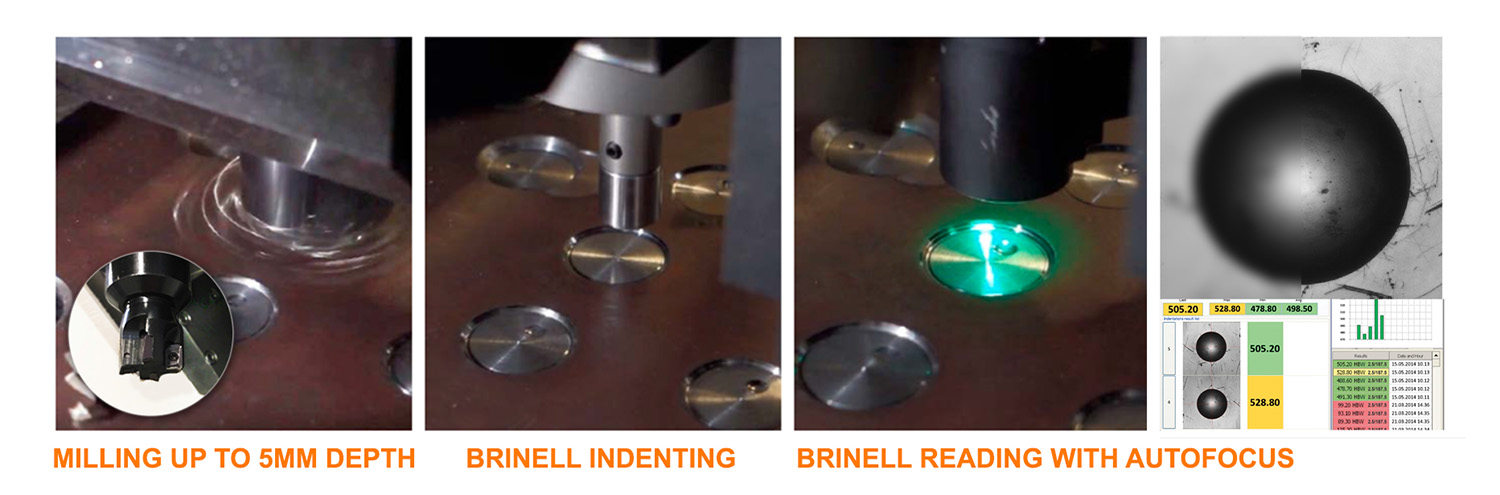

FULLY AUTOMATED BRINELL HARDNESS TESTER WITH SAMPLE PREPARATION BY MILLING

- Automatic detection and positioning of the sample for precise alignment.

- Auto-milling to the programmed depth, ensuring consistent surface preparation.

- Auto-indent and application of load with precise control, guaranteeing accurate indentation.

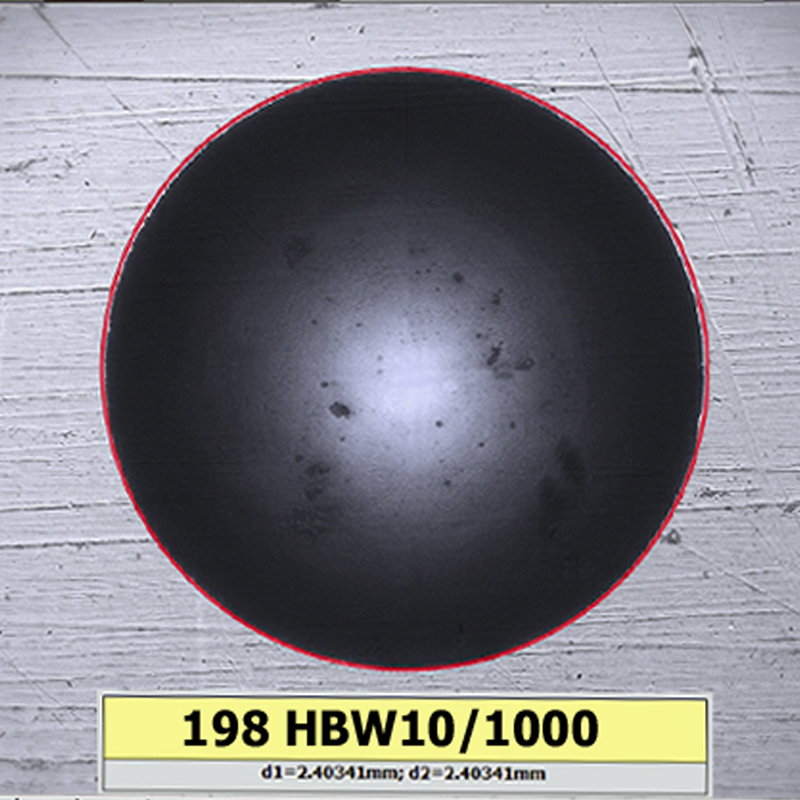

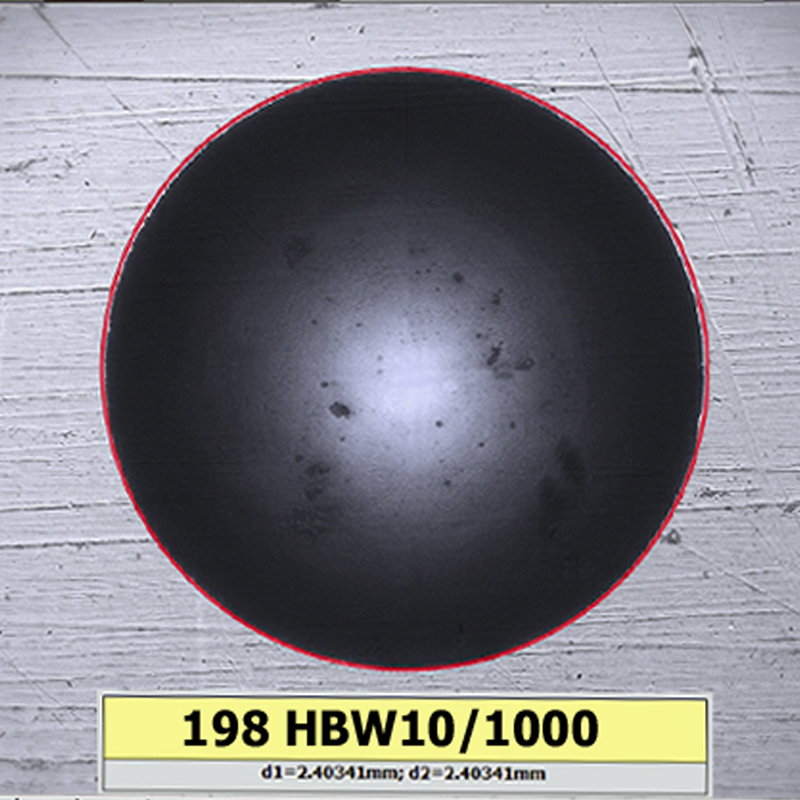

- Automatic reading with autofocus, allowing for clear and precise measurement of the indentation.

- Autoreturn function, which moves the sample back to its original position and proceeds to the next test location.

This automated approach significantly reduces manual labor, increases testing efficiency, and improves accuracy by eliminating human error and inconsistencies.

FULLY AUTOMATED BRINELL HARDNESS TESTER WITH SAMPLE PREPARATION BY MILLING

- Automatic detection and positioning of the sample for precise alignment.

- Auto-milling to the programmed depth, ensuring consistent surface preparation.

- Auto-indent and application of load with precise control, guaranteeing accurate indentation.

- Automatic reading with autofocus, allowing for clear and precise measurement of the indentation.

- Autoreturn function, which moves the sample back to its original position and proceeds to the next test location.

This automated approach significantly reduces manual labor, increases testing efficiency, and improves accuracy by eliminating human error and inconsistencies.

SAVE TIME AND MONEY,

INCREASE ACCURACY

- 45 sec for one complete test including surface preparation

- Test 100% of production with maximum Brinell accuracy

- Automatize the quality inspection process

- Move human resources to other jobs

- Always the same surface roughness, no risk of damaging or heating the testing surface

- The total cost of the machine is absorbed in one year

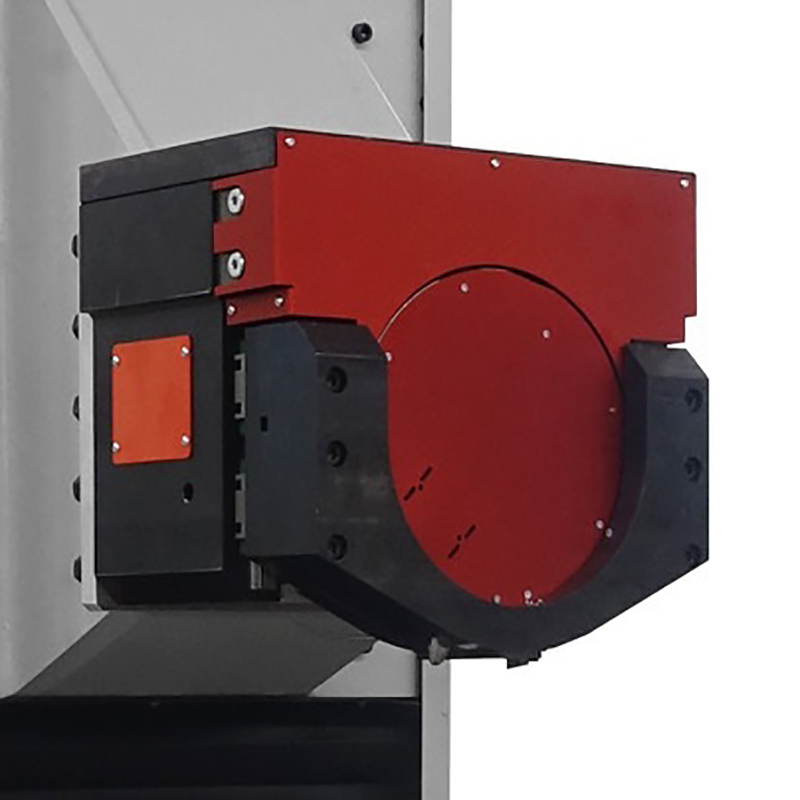

THE EXCLUSIVE MILLING TOOL

EASYDUR Integral 1 universal hardness tester can be fitted with a sample preparation system that is directly mounted on the instrument’s head.

- Save time! Only 30 seconds to get the Brinell result!

- Increase the accuracy and the quality of your Brinell results

- Automatize the quality inspection process

- Move human resources to other jobs

MAIN FEATURES

MAIN FEATURES

MAIN FEATURES

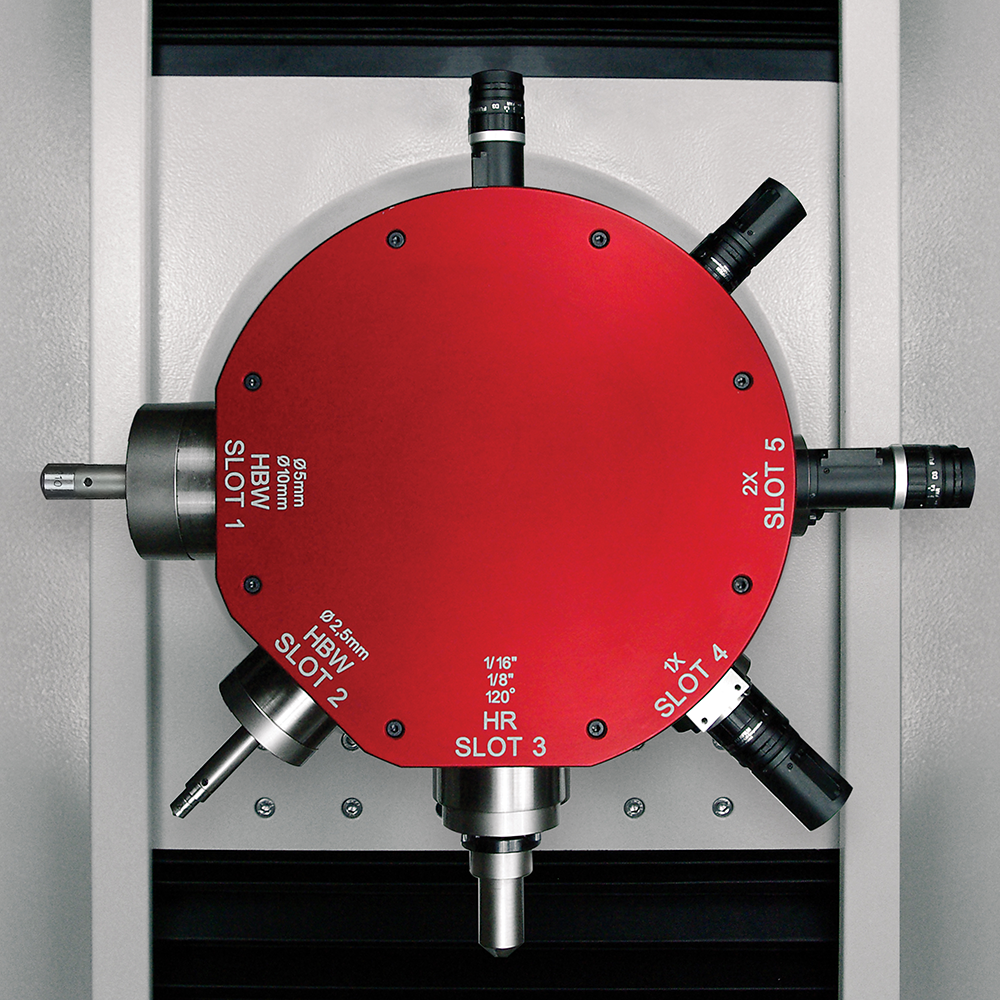

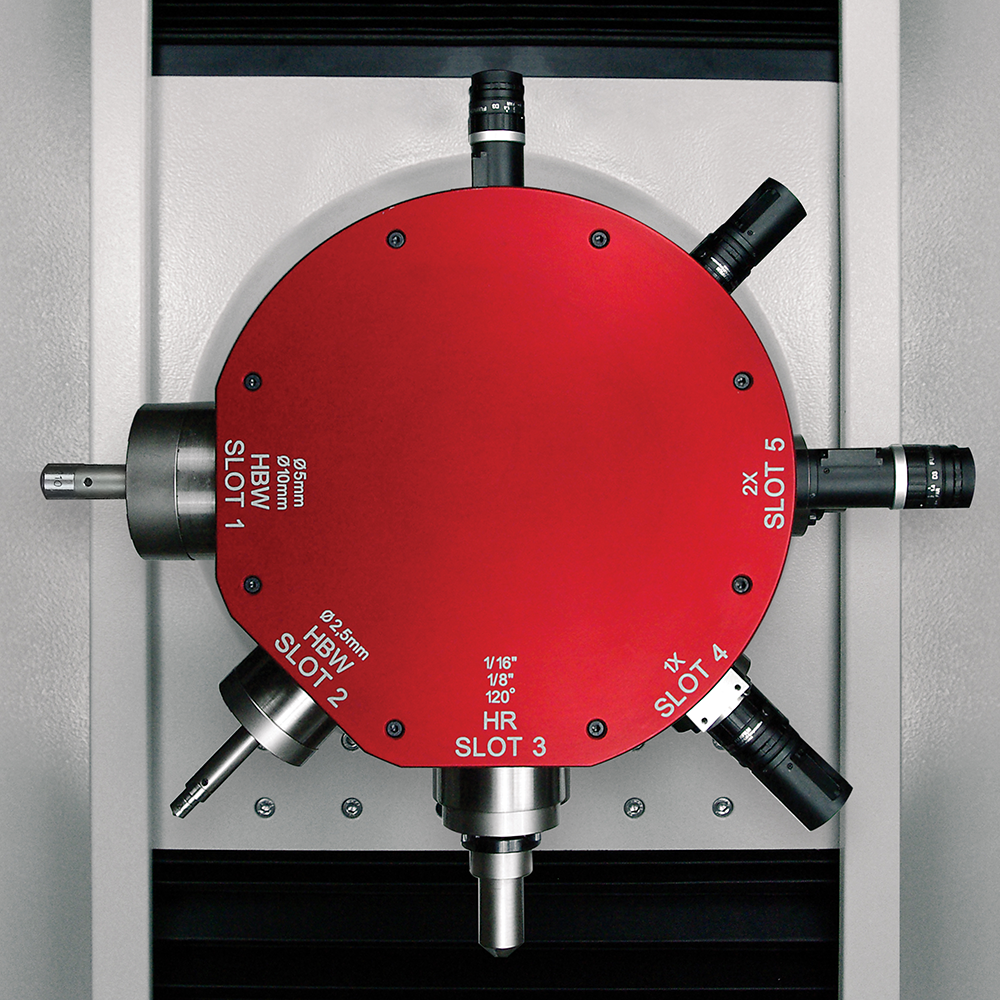

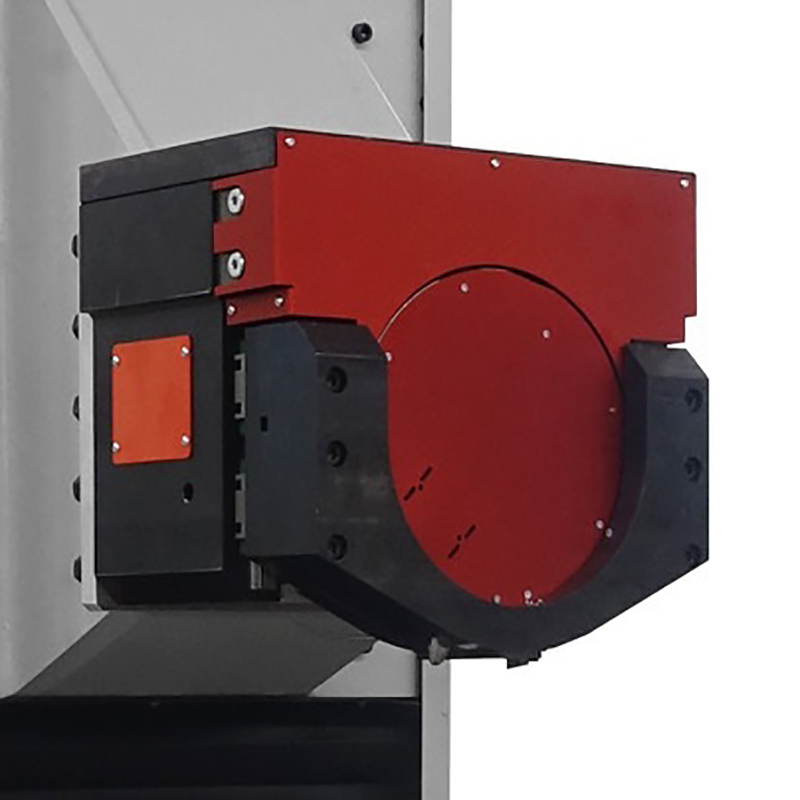

MOTORIZED TURRET

The system offers up to 8 slots (or more) for a variety of hardness scale indenters, different optical lenses, lasers, and even a milling tool for surface preparation. It includes automatic rotation and tool switching, ensuring a fully automated testing process. This allows for both single and multi-hardness testing with a single device.

CLAMPING SYSTEM

A secure connection with the specimen is consistently maintained, even in the rare case of any movement during the test cycle. The clamping system guarantees full stability of the test piece throughout the entire process, regardless of its whether condition oiled, rusty, or contaminated with dirt.

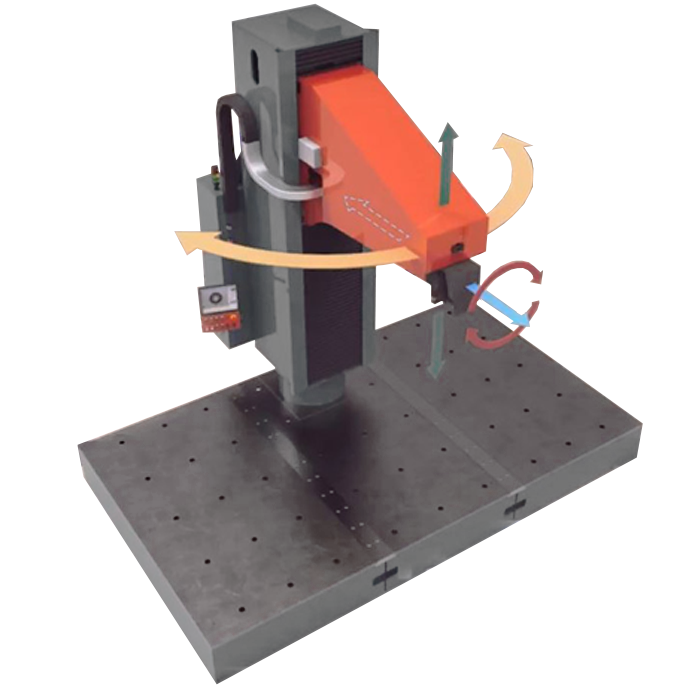

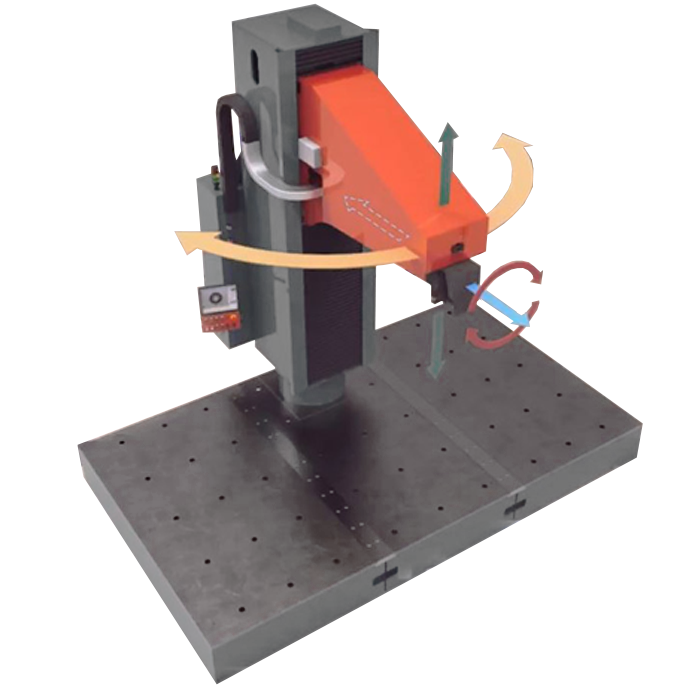

AUTO LEARNING SYSTEM

The Easyflag 3000 is entirely motorized, allowing it to move effortlessly in all directions with micrometric precision. Users can program custom paths, enabling the system to automatically test multiple samples in a seamless, consecutive sequence. This feature enhances efficiency by minimizing manual intervention and ensuring consistent results across all tests.

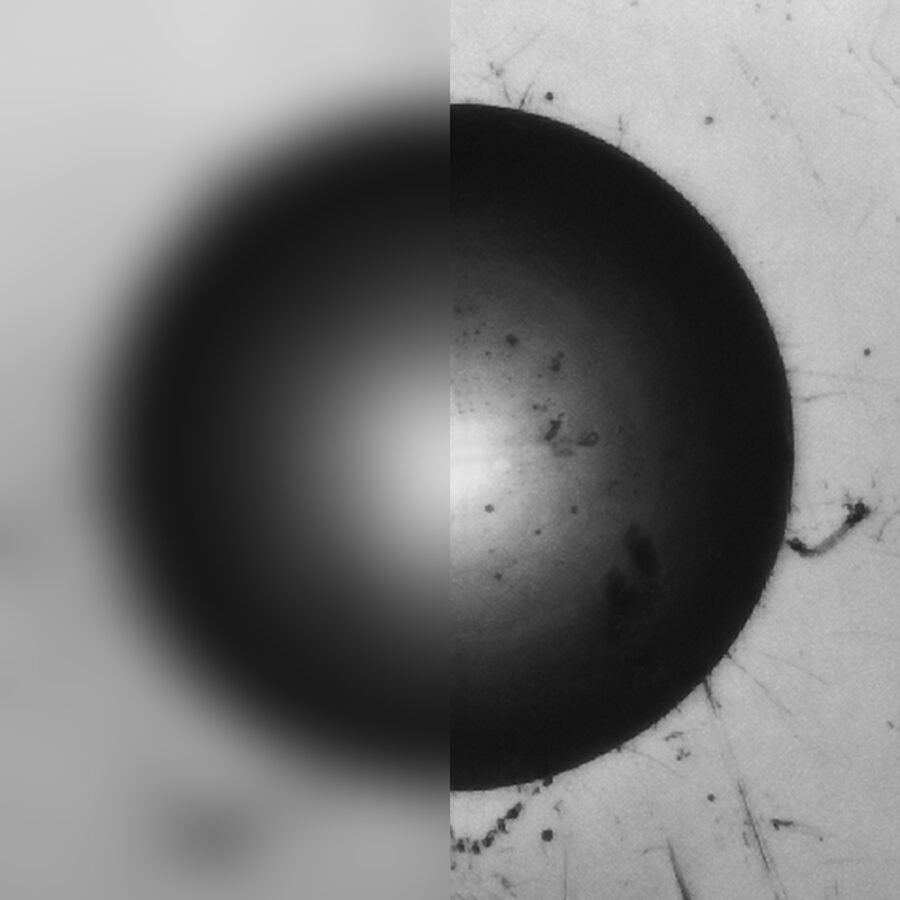

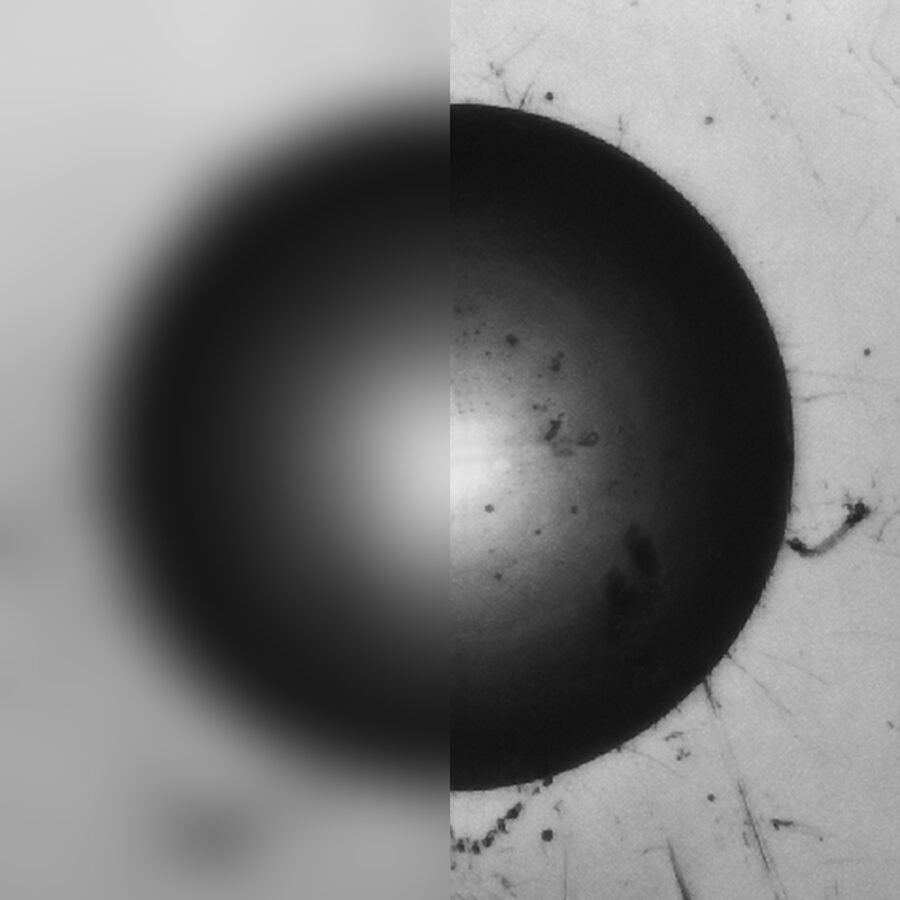

AUTOFOCUS

The automatic focus adjustment system for each optic ensures precise positioning at any magnification, utilizing real image brightness scanning with continuous steps for infinite accuracy. This technology guarantees high reading standards, reproducible focus values, and reduces reading time. Hardness measurements remain objective, unaffected by subjectivity.

CAMERA AUTO-READING

The software automatically measures indentations on any sample surface, ranging from perfectly polished to rough or etched materials. It features automatic light regulation for dark, opaque, or polished samples, adjusting both light and contrast to optimize visibility and ensure accurate indentation measurements.

EASYFLAG MINI

Smaller stand support with motorization on the vertical axis of the head. Base plate 2700 x 2000 mm, working test height 1500 mm, depth capacity 1000 mm. (Possibility to motorize all axis).

MAIN FEATURES

MOTORIZED TURRET

The system offers up to 8 slots (or more) for a variety of hardness scale indenters, different optical lenses, lasers, and even a milling tool for surface preparation. It includes automatic rotation and tool switching, ensuring a fully automated testing process. This allows for both single and multi-hardness testing with a single device.

CLAMPING SYSTEM

A secure connection with the specimen is guaranteed throughout the test, even in the rare case of specimen movement during the testing cycle. The clamping system ensures full stability of the test piece, regardless of its condition whether oiled, rusted, or contaminated with dirt throughout the entire testing process.

AUTO LEARNING SYSTEM

The Easyflag 3000 is entirely motorized, allowing it to move effortlessly in all directions with micrometric precision. Users can program custom paths, enabling the system to automatically test multiple samples in a seamless, consecutive sequence. This feature enhances efficiency by minimizing manual intervention and ensuring consistent results across all tests.

AUTOFOCUS

The automatic focus adjustment system for each optic ensures precise positioning at any magnification, utilizing real image brightness scanning with continuous steps for infinite accuracy. This technology guarantees high reading standards, reproducible focus values, and reduces reading time. Hardness measurements remain objective, unaffected by subjectivity.

AUTOFOCUS

The automatic focus adjustment system for each optic ensures precise positioning at any magnification, utilizing real image brightness scanning with continuous steps for infinite accuracy. This technology guarantees high reading standards, reproducible focus values, and reduces reading time. Hardness measurements remain objective, unaffected by subjectivity.

EASYFLAG MINI

Smaller stand support with motorization on the vertical axis of the head. Base plate 2700 x 2000 mm, working test height 1500 mm, depth capacity 1000 mm. (Possibility to motorize all axis).