AFFRI MK II

Portable Hardness Tester for test on sites

AFFRI MK II is a portable hardness tester conforms to ASTM E3246-22, ASTM E10-23, ASTM E384-22, ASTM E18, ISO 6506, ISO 6507, ISO 6508 and GB 230 standards. Test Loads from 2 to 5,6 kg and able to test sample with a minimum thickness of 0.06 mm.

- Test loads 2 – 5,6 kgf (19,614 – 54,92 N)

- Rockwell – Brinell – Vickers – Knoop HRA (20…92); HRB (26…100); HRC (0…80) HR15N (69…93); HR30T (16…83) HB5 (5…205); HB30 (66…884) HV (13…1865) / HK (25…97)

PORTABLE HARDNESS TESTER WITH ACCURATE MEASUREMENTS

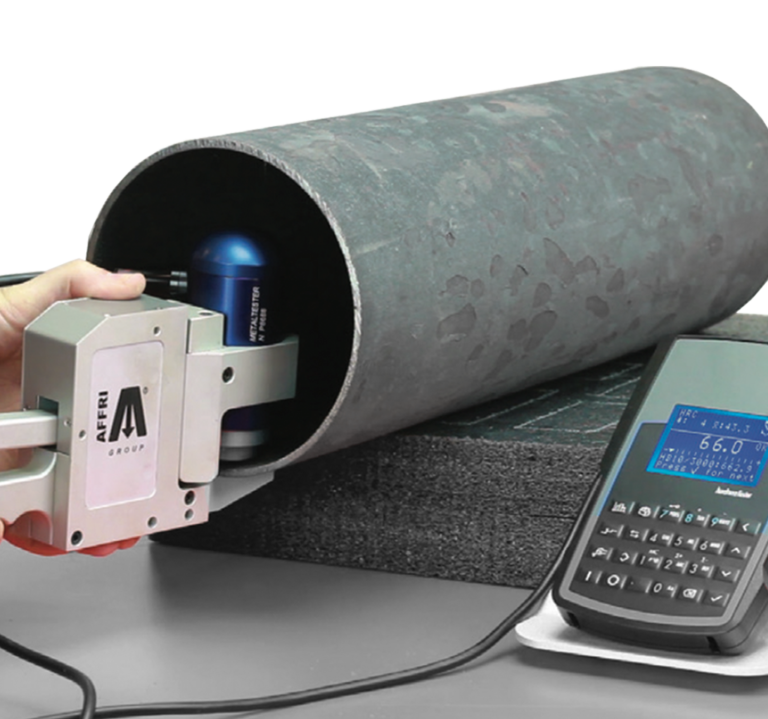

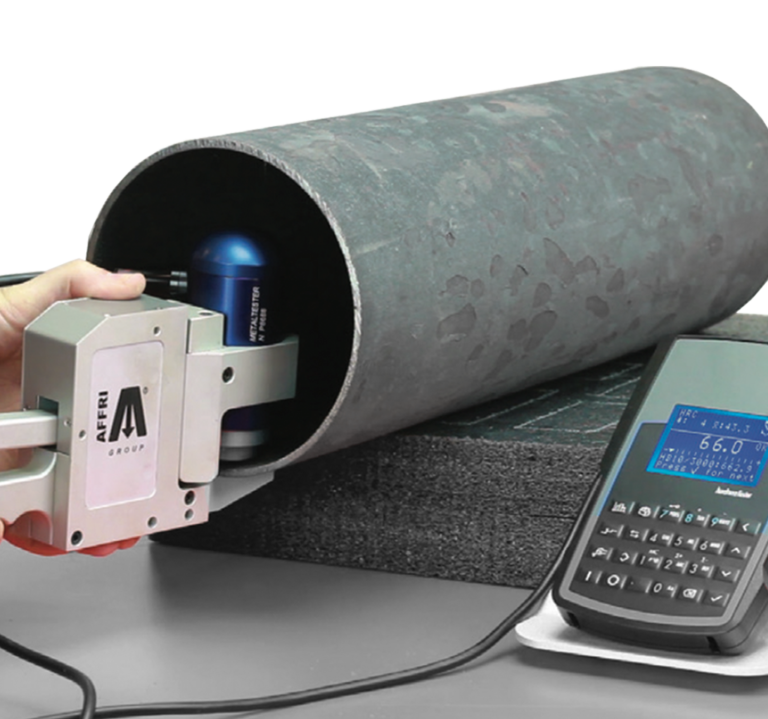

The compact and lightweight portable hardness tester applies load forces through a dynamometric load cell, offering 360° positioning flexibility, including upside-down orientation. It is suitable for hardness testing both in the laboratory and on the production floor, allowing for tests on tubes, profiles, valves, and both large and small parts with a minimum thickness of 0.06 mm. The small penetration depth ensures accurate results on thin surfaces, such as chrome coatings or delicate components like shave blade profiles. It can test a wide range of metals, including chromed and nitrided surfaces, aluminum, brass, copper, bronze, metal wire, as well as hard and soft steel.

EXTREMELY EASY TO USE:

- Select the desired hardness scale.

- Place the test probe on the surface and apply light pressure to initiate the test cycle.

- Once the test is complete, the instrument emits a sound signal, and the result is displayed instantly on the large graphic screen.

- The hardness tester is immediately ready for the next measurement

ABSOLUTE CLAMPING SYSTEM ON ANY TEST SURFACES

From round to flat surfaces, the indenter automatically aligns with the measurement axis, ensuring high accuracy with every measurement, even on flexible surfaces. Completely unaffected by orientation, these testers can operate in any position, offering full 360° rotation, including upside-down.

A range of accessories is available to support testing on small, irregularly shaped parts, or finished components.

PUSH WITH CONFIDENCE!

The force applied to the probe has no impact on the results. The precise testing force is ensured by the internal dynamometric load cell, providing consistent accuracy in all conditions and over time.

THE ESSENTIAL HAND-CLAMP TOOL

The HARDTEST hand clamp system is an invaluable accessory, particularly for testing challenging items such as springs, wires, and profiles. It is designed to work seamlessly with the MKII or METALTEST, securely holding the specimen in place to prevent any movement during the measurement process, ensuring precise and stable results. With a testing capacity of 30 x 30 mm, it provides both safety and ease of use. The system is equipped with an anvil and a variety of accessories to accommodate different testing needs.

The HARDTEST hand clamp offers a reliable clamping mechanism to firmly lock the sample in position for testing. However, due to the unique shapes of certain samples, we recommend utilizing specific optional supports to ensure optimal stability and accurate positioning for standard hardness tests. Several types of supports are available, and custom solutions can be developed to meet specific customer requirements. Below are examples of the main supports; additional options can be tailored as needed to accommodate a wider range of sample types and testing conditions.

ABSOLUTE ACCURACY ON ANY SURFACES

With AFFRI portable hardness testers, MKII and METALTEST, users can quickly and accurately perform Rockwell, Brinell, and Vickers hardness tests, utilizing the same advanced methods and technology found in standard bench-top instruments. Each complete measurement takes only 3 seconds (or longer with standardized dwell time). The testers are capable of measuring materials with a minimum thickness of > 0.06 mm, ensuring precise results on thin metal sheets, chromium coatings, rolled steel, and profiles. Featuring a true Rockwell measurement system with a diamond indenter and depth measurement, the testers offer direct readings in various hardness scales, including Brinell, Vickers, Rockwell, Knoop, Shore, Webster, Barcol, N/mm², as well as test temperature measurements. You can test incoming materials directly from the truck. Compact and portable, the hardness tester can be easily transported to any location.

- Only 3 seconds to complete the hardness test cycle.

- Minimum thickness > 0.06 mm. Accurate measurements on thin metal sheets, coating chromium surface, rolled steel and profiles.

- A real Rockwell measuring system with diamond indenter and depth measurement.

- MK II portable hardness tester allows you to save money and time thanks to its portable shape.

THE OPERATIVE CONSOLE

The portable hardness tester MKII has a smart digital console with LCD screen, large hard disk for data and statistics storage and data outputs that connect to a printer or computer, with an RS232C connection or USB connection upon request. Hardness testing data are simultaneously shown on the LCD graphic display:

- Detected values in various simultaneous scales

- Average of the values with automatic updating

- Battery level

- Results according to the tolerance limits expressed both numerically and graphically

- Programmable test preload and load timer

- Statistics and Gauss diagram, sound signal to indicate the end of the cycle

- Display the environment temperature and the date.

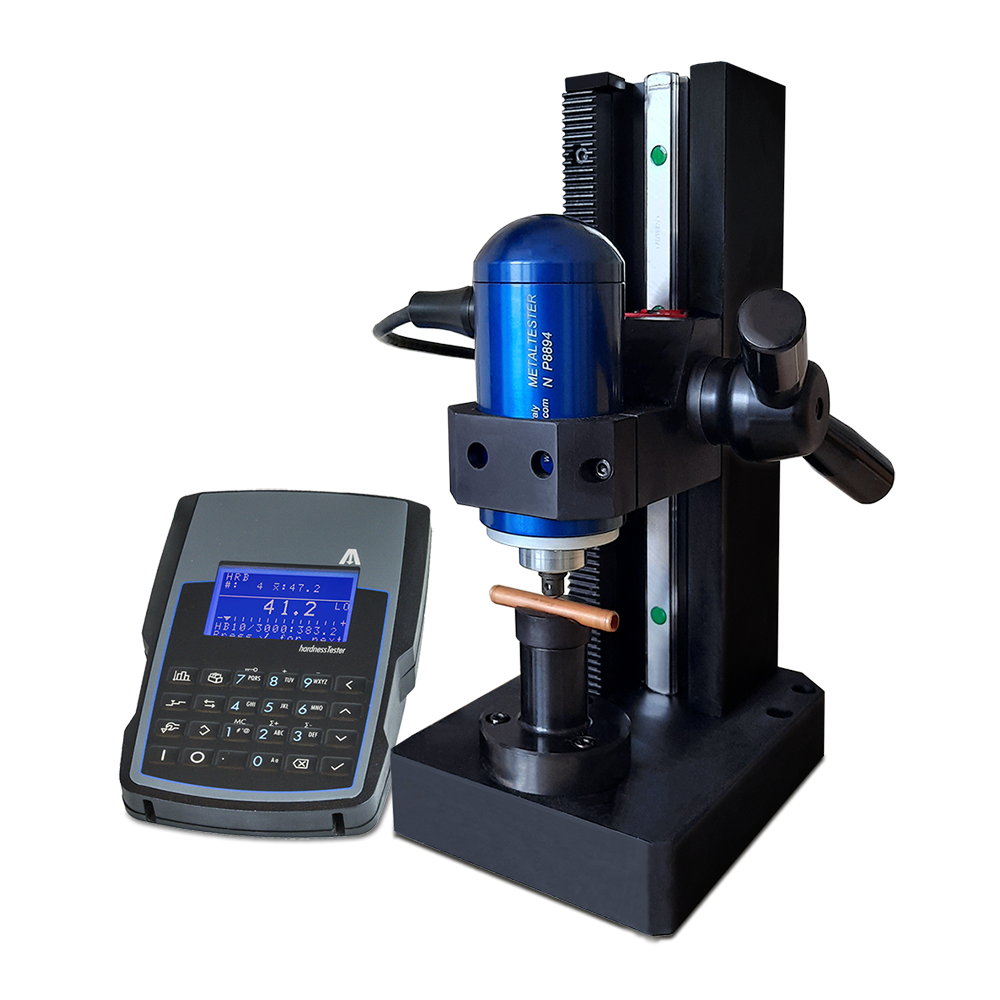

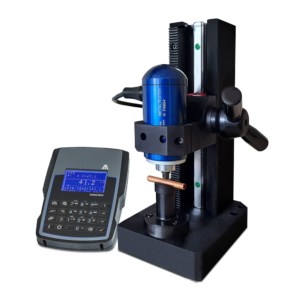

FROM PORTABLE TO BECH-TOP HARDNESS TESTER

MKII portable hardness tester can be configured as a bench-top unit using Microtester (manual) or EDA300 (motorized) stand. This setup ensures accurate, repeatable testing on small samples, with automatic deflection compensation and integrated clamping—delivering performance equivalent to AFFRI bench-top systems.

MICROTESTER

Manual stand support for the laboratory, where it is necessary to test small sized items. (Only for MKII)

Height Capacity: 170 mm

Depth Capacity: 75 mm

EDA 300

Motorized stand support for the laboratory, where it is necessary to test small sized items. (Only for MKII)

Height capacity: 110 mm

Depth capacity: 60 mm

PORTABLE HARDNESS TESTER MODELS

MKII

Tester with smart digital console with LCD screen, large hard disk for data and statistics storage and data outputs (RS232 / USB) for printer or computer.

METALTEST

Wireless and pocket tester with embedded display and commands. Extremely easy to use and always ready for all measurement condition and surfaces.

AFFRI MK II

Portable Hardness Tester for test on sites

AFFRI MK II is a portable hardness tester conforms to ASTM E3246-22, ASTM E10-23, ASTM E384-22, ASTM E18, ISO 6506, ISO 6507, ISO 6508 and GB 230 standards. Test Loads from 2 to 5,6 kg and able to test sample with a minimum thickness of 0.06 mm.

- Test loads 2 – 5,6 kgf (19,614 – 54,92 N)

- Rockwell – Brinell – Vickers – Knoop HRA (20…92); HRB (26…100); HRC (0…80) HR15N (69…93); HR30T (16…83) HB5 (5…205); HB30 (66…884) HV (13…1865) / HK (25…97)

FRIENDLY USE AND ACCURATE MEASUREMENTS

The compact and lightweight portable hardness tester applies load forces through a dynamometric load cell, offering 360° positioning flexibility, including upside-down orientation. It is suitable for hardness testing both in the laboratory and on the production floor, allowing for tests on tubes, profiles, valves, and both large and small parts with a minimum thickness of 0.06 mm. The small penetration depth ensures accurate results on thin surfaces, such as chrome coatings or delicate components like shave blade profiles. It can test a wide range of metals, including chromed and nitrided surfaces, aluminum, brass, copper, bronze, metal wire, as well as hard and soft steel.

EXTREMELY EASY TO USE:

- Select the desired hardness scale.

- Place the test probe on the surface and apply light pressure to initiate the test cycle.

- Once the test is complete, the instrument emits a sound signal, and the result is displayed instantly on the large graphic screen.

- The hardness tester is immediately ready for the next measurement

ABSOLUTE CLAMPING SYSTEM ON ANY SURFACE

From round to flat surfaces, the indenter automatically aligns with the measurement axis, ensuring high accuracy with every measurement, even on flexible surfaces. Completely unaffected by orientation, these testers can operate in any position, offering full 360° rotation, including upside-down.

A range of accessories is available to support testing on small, irregularly shaped parts, or finished components.

PUSH WITH CONFIDENCE!

The force applied to the probe has no impact on the results. The precise testing force is ensured by the internal dynamometric load cell, providing consistent accuracy in all conditions and over time.

THE ESSENTIAL CLAMP-TOOL

The HARDTEST hand clamp system is an invaluable accessory, particularly for testing challenging items such as springs, wires, and profiles. It is designed to work seamlessly with the MKII or METALTEST, securely holding the specimen in place to prevent any movement during the measurement process, ensuring precise and stable results. With a testing capacity of 30 x 30 mm, it provides both safety and ease of use. The system is equipped with an anvil and a variety of accessories to accommodate different testing needs.

The HARDTEST hand clamp offers a reliable clamping mechanism to firmly lock the sample in position for testing. However, due to the unique shapes of certain samples, we recommend utilizing specific optional supports to ensure optimal stability and accurate positioning for standard hardness tests. Several types of supports are available, and custom solutions can be developed to meet specific customer requirements. Below are examples of the main supports; additional options can be tailored as needed to accommodate a wider range of sample types and testing conditions.

ABSOLUTE ACCURACY

With AFFRI portable hardness testers, MKII and METALTEST, users can quickly and accurately perform Rockwell, Brinell, and Vickers hardness tests, utilizing the same advanced methods and technology found in standard bench-top instruments. Each complete measurement takes only 3 seconds (or longer with standardized dwell time). The testers are capable of measuring materials with a minimum thickness of > 0.06 mm, ensuring precise results on thin metal sheets, chromium coatings, rolled steel, and profiles. Featuring a true Rockwell measurement system with a diamond indenter and depth measurement, the testers offer direct readings in various hardness scales, including Brinell, Vickers, Rockwell, Knoop, Shore, Webster, Barcol, N/mm², as well as test temperature measurements. You can test incoming materials directly from the truck. Compact and portable, the hardness tester can be easily transported to any location.

- Only 3 seconds to complete the hardness test cycle.

- Minimum thickness > 0.06 mm. Accurate measurements on thin metal sheets, coating chromium surface, rolled steel and profiles.

- A real Rockwell measuring system with diamond indenter and depth measurement.

- MK II portable hardness tester allows you to save money and time thanks to its portable shape.

THE OPERATIVE CONSOLE

The portable hardness tester MKII has a smart digital console with LCD screen, large hard disk for data and statistics storage and data outputs that connect to a printer or computer, with an RS232C connection or USB connection upon request. Hardness testing data are simultaneously shown on the LCD graphic display:

- Detected values in various simultaneous scales

- Average of the values with automatic updating

- Battery level

- Results according to the tolerance limits expressed both numerically and graphically

- Programmable test preload and load timer

- Statistics and Gauss diagram, sound signal to indicate the end of the cycle

- Display the environment temperature and the date.

FROM PORTABLE TO BENCH-TOP HARDNESS TESTER

MKII portable hardness tester can be configured as a bench-top unit using Microtester (manual) or EDA300 (motorized) stand. This setup ensures accurate, repeatable testing on small samples, with automatic deflection compensation and integrated clamping—delivering performance equivalent to AFFRI bench-top systems.

MICROTESTER

Manual stand support for the laboratory, where it is necessary to test small sized items. (Only for MKII)

Height Capacity: 170 mm

Depth Capacity: 75 mm

EDA 300

Motorized stand support for the laboratory, where it is necessary to test small sized items. (Only for MKII)

Height capacity: 110 mm

Depth capacity: 60 mm

PORTABLE HARDNESS TESTER MODELS

MKII

Tester with smart digital console with LCD screen, large hard disk for data and statistics storage and data outputs (RS232 / USB) for printer or computer.

METALTEST

Wireless and pocket tester with embedded display and commands. Extremely easy to use and always ready for all measurement condition and surfaces.