AFFRI LD 3000 AX

Automatic Universal hardness Testers

The system supports Rockwell, Superficial Rockwell, Brinell, Brinell HBT, and Vickers hardness testing methods. It is an automatic hardness testing machine capable of applying test loads ranging from 1 to 3000 kgf. The device ensures precise hardness measurements for all metals and alloys, fully compliant with ASTM, DIN, and EN ISO international standards.

- Test loads ranges From 1 to 250 kgf (9,807 to 2452 N) From 3 to 3000 kgf (29.4 to 29421 N)

- Rockwell ISO 6508 / ASTM E-18: HRA – HRB – HRC – HRD – HRE – HRF – HRG – HRH – HRK – HRL – HRM – HRP – HRR – HRV / HRN – HRT – HRS – HRW – HRX – HRY

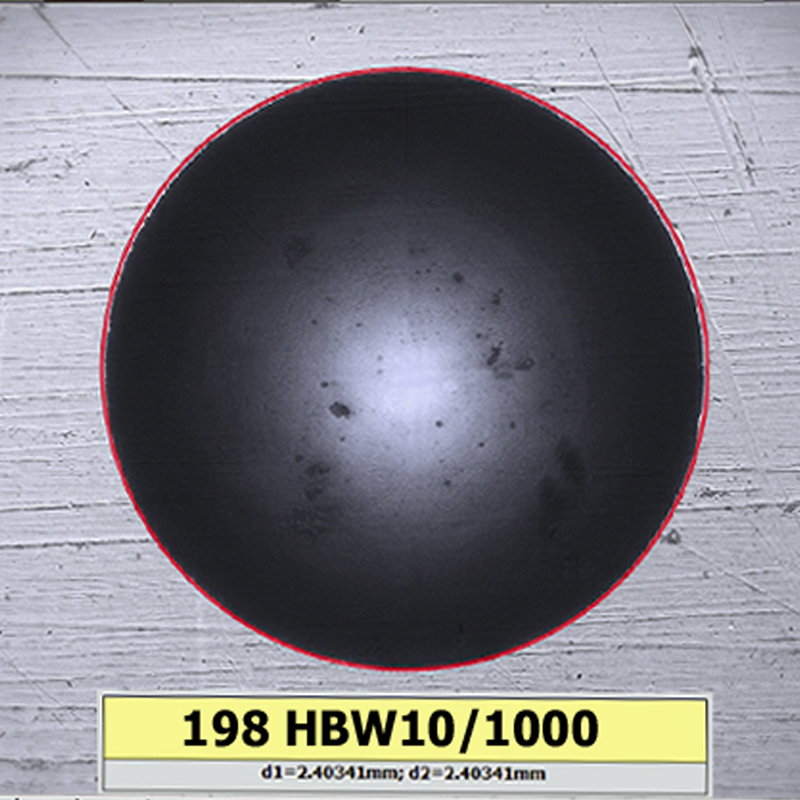

- Brinell HBW ISO 6506 / ASTM E-10 – HBWT ASTM E103 HBW 1/1 – HBW 1/1.25 – HBW 1/2.5 – HBW 1/5 – HBW 1/30 – HBW 2.5/6.25 – HBW 2.5/7.8125 – HBW 2.5/15.625 – HBW 2.5/31.25 – HBW 2.5/62.5 – HBW 2.5/187.5 – HBW 5/25 – HBW 5/31.25 – HBW 5/62.5 – HBW 5/125 – HBW 5/250 – HBW 5/750 – HBW 10/100 – HBW 10/125 – HBW 10/250 – HBW 10/500 – HBW 10/1000 – HBW 10/1500 – HBW 10/3000

- Vickers ISO 6507 / ASTM E-384 / ASTM E-92 HV1 – HV2 – HV3 – HV5 – HV10 – HV20 – HV30 – HV50 – HV100

One Touch Measurement

AFFRI LD3000AX is an advanced, fully automatic system designed for Brinell, Vickers, Rockwell, and Superficial Rockwell hardness testing, in full compliance with ASTM and ISO hardness standards. AFFRI System hardness testers are engineered to provide unparalleled load accuracy and measurement resolution, ensuring the most precise results for hardness testing. With the AFFRI System, true indentation measurement is guaranteed, unaffected by any external factors or environmental conditions. The testing process is simple, fast, and highly reliable. The entire hardness test cycle is fully automated and motorized with a single operation, initiated by pressing a button or selecting an icon.

Key features include:

- Automatic contact with the specimen for seamless testing

- Auto-active sliding clamping to secure the test piece

- Automatic preloading and loading of the specimen

- Swift and precise switching to the appropriate optical lens

- Autofocus functionality based on image scanning brightness

- Real-time measurement and result display

- Automatic return stroke at a pre-programmed distance for consistent results

This highly efficient system minimizes user intervention, streamlining the testing process while maintaining exceptional accuracy and reliability throughout the cycle.

Auto-contat and Clamping System

The test cycle is automatically triggered when the head contacts the specimen, which is instantly detected at any position within the vertical stroke. The top surface referencing design minimizes errors typically caused by contaminants or scale buildup, reducing the need for extensive sample preparation. This design enhancement improves both the accuracy and speed of the testing process.

- Vertical capacity from base to the indenter 300mm / 12″ (more on request)

- Horizontal capacity from column to the indenter 190 mm / 7.4” (more on request)

Auto-compensation of All Deflections

When testing unstable or deflecting samples, the AFFRI System ensures continuous contact with the specimen, thanks to its infinite stroke capability for both the indenter and clamping hood. This allows the system to track the sample without interruption.

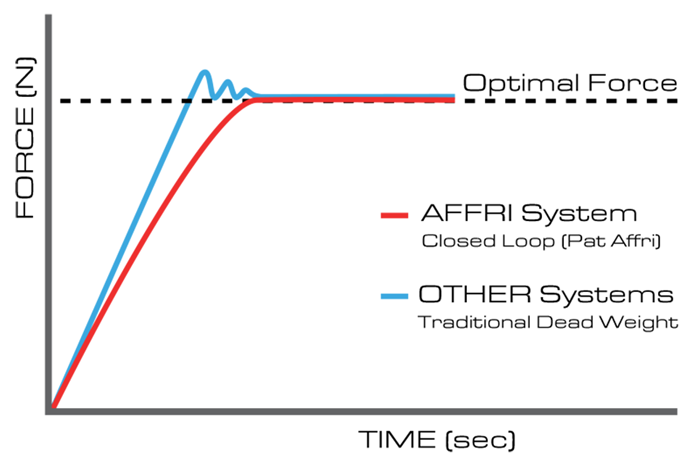

The Closed Loop Control

Load forces are applied via load cells and regulated in a Closed-Loop system with a frequency of 1 kHz, ensuring perfect linearity across all ranges. Structural deflections, misalignments, or vibrations do not affect the results. Precise measurements are achieved on the first test, even under challenging conditions, eliminating the need for repeated trials. The system’s R&R (Repeatability and Reproducibility) data is among the best in its class.

The EXCLUSIVE MILLING TOOL

Universal hardness tester LD 3000 AX can be equipped with a sample preparation system that is directly installed on the head of the instrument.

- Save time! Only 30 seconds to get the Brinell result!

- Increase the accuracy and the quality of your Brinell results

- Automatize the quality inspection process

- Move human resources to other jobs

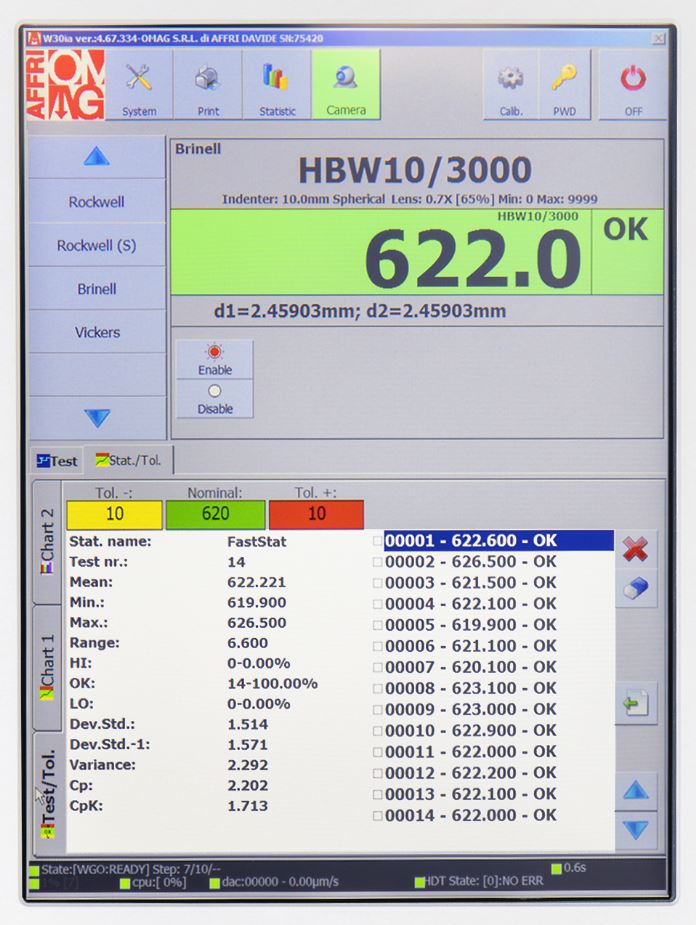

Software

The universal hardness tester AFFRI LD 3000 AX is equipped with a pre-installed software that controls the whole instrument during the entire cycle avoiding operator errors.

- Touchscreen 15″

- User-friendly software

- Color highlighted results (low/ok/high)

- Live statistics and graph

- Programs of test settings

- Results archives

- Save images

- Export results to PDF, TXT, CSV, DOC, XLS, and more

- Data enter via bar-code scanning

- Outputs via RS232, USB, and Ethernet

- Data exchange with management system MES

MAIN FEATURES

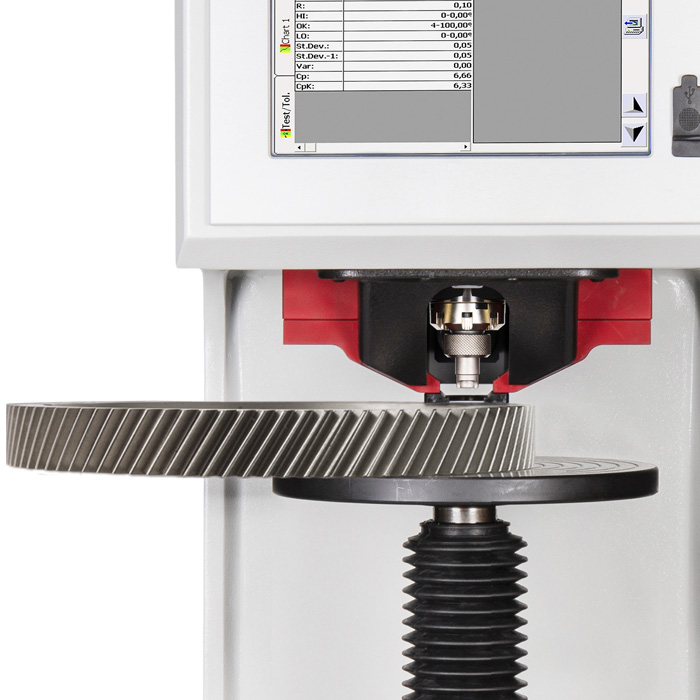

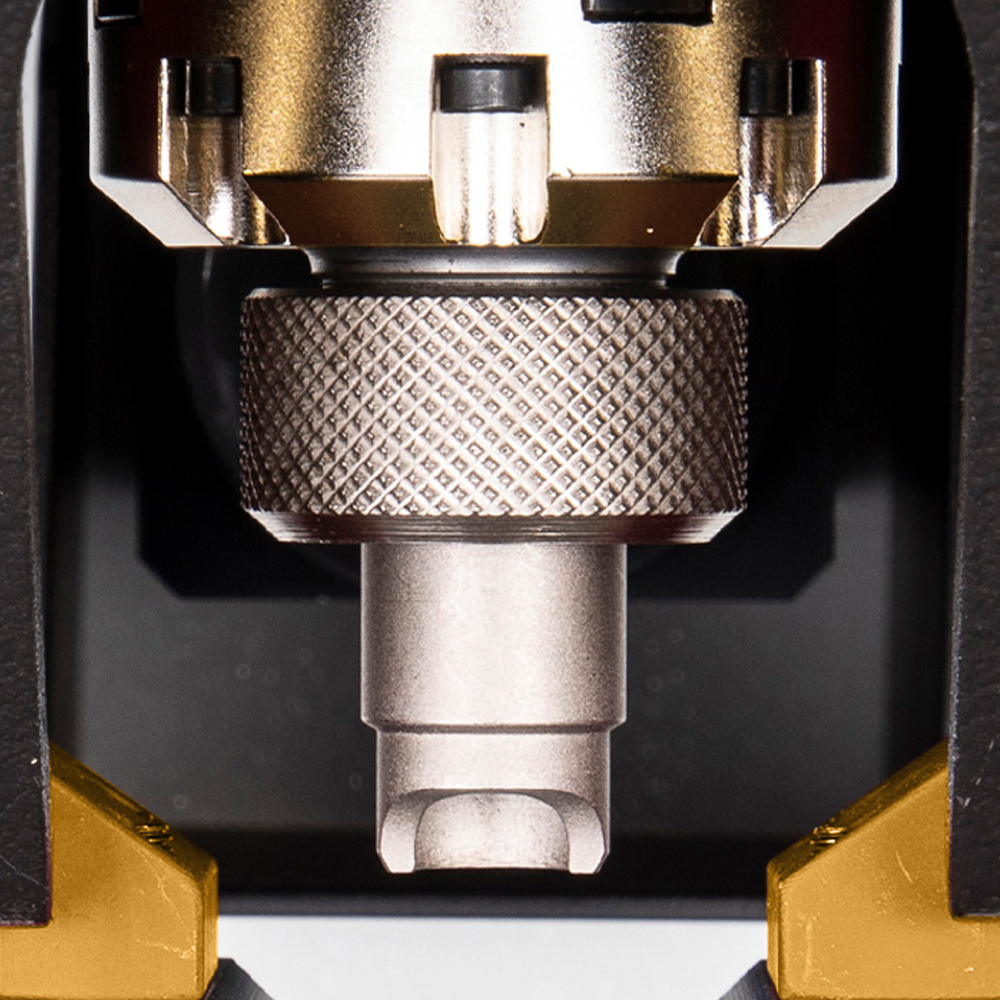

MOTORIZED TURRET

The automatic two-position turret features one indenter and one objective, both of which can be easily swapped using manual screwing. It offers auto-rotation, auto-tool switching, and auto-centering for a fully automated hardness testing cycle. (An 8-position turret is available upon request.)

MAIN FEATURES

CLAMPING SYSTEM

A secure connection with the specimen is guaranteed throughout the test, even in the rare case of specimen movement during the testing cycle. The clamping system ensures full stability of the test piece, regardless of its condition whether oiled, rusted, or contaminated with dirt throughout the entire testing process.

MAIN FEATURES

FOCUS DRIVE

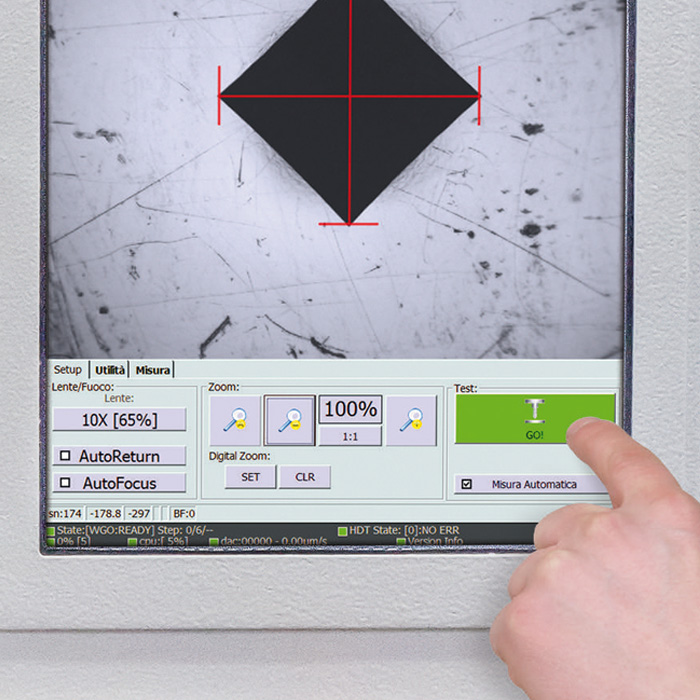

The hardness testing cycle is fully automated, initiated with a single input for fast and precise measurements. However, in certain cases, the automatic measurement and autofocus functions can be overridden, allowing for manual focus and reading.

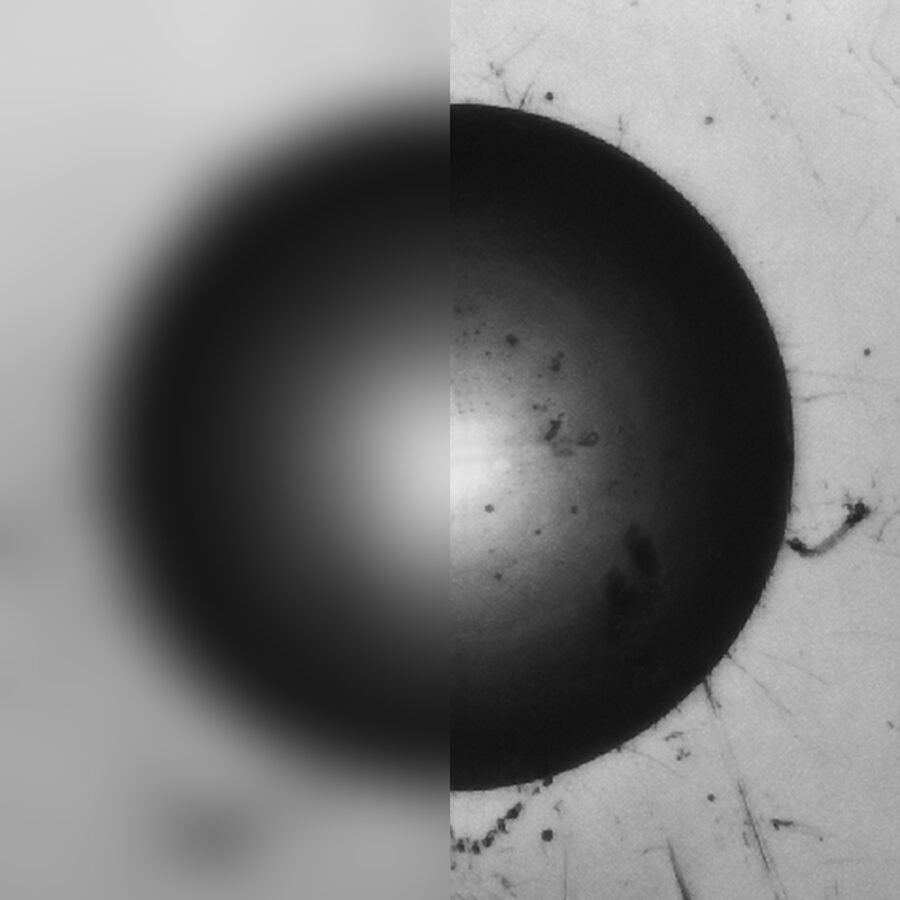

AUTOFOCUS

The automatic focus adjustment system for each optic ensures precise positioning at any magnification, utilizing real image brightness scanning with continuous steps for infinite accuracy. This technology guarantees high reading standards, reproducible focus values, and reduces reading time. Hardness measurements remain objective, unaffected by subjectivity.

AUTOFOCUS

The automatic focus adjustment system for each optic ensures precise positioning at any magnification, utilizing real image brightness scanning with continuous steps for infinite accuracy. This technology guarantees high reading standards, reproducible focus values, and reduces reading time. Hardness measurements remain objective, unaffected by subjectivity.

PROTECTED DIAMOND INDENTER

All Affri diamond indenters are designed for extended longevity, thanks to a specialized protective cup. This cup retracts and lowers immediately after the test piece is secured, effectively minimizing the risk of accidental impact.