AFFRI IRHD

Fully Motorized Hardness Tester for Plastics and Rubbers

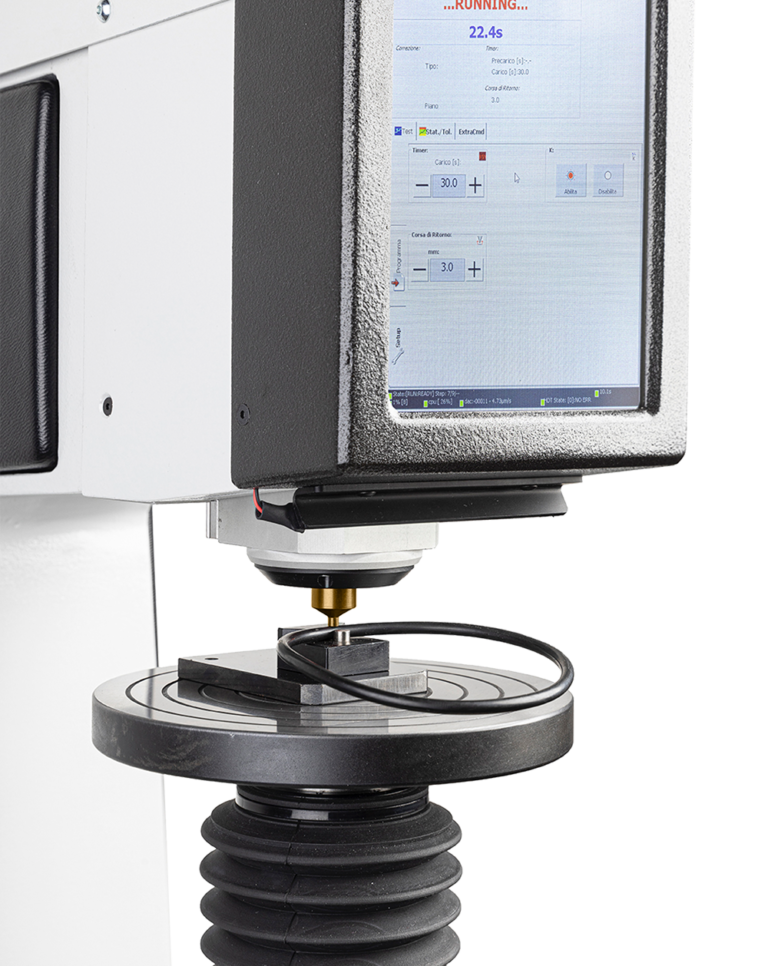

AFFRI IRHD is a fully automated hardness tester designed for plastics and rubber materials. The measurement process and the indenter’s contact with the sample are entirely managed by advanced software, while load cells are electronically controlled using a Closed-Loop system (AFFRI patent). This technology eliminates manual errors and minimizes the impact of external vibrations. With a single command, the tester automatically identifies the sample, clamps it securely, and displays the results.

AFFRI IRHD hardness tester enhances measurement accuracy, repeatability, and reproducibility by eliminating human errors. Testing O-rings is straightforward with dedicated sample holders for each chord size, compliant with ISO 48 and ASTM 1414, without requiring manual adjustments. All measurement data is stored on the computer’s hard drive and can be analyzed for statistical evaluations.

IRHD L – H – N

High-definition of 0.01 IRHD

ISO 48 and ASTM 1415

One Button Measurements

Simply press the start button, and the hardness tester will automatically execute the entire testing cycle in seamless succession:

- Automatic approach and contact with the sample

- Sample clamping

- Measurement execution

- Sample release

Once the cycle is complete, the results are instantly displayed on the large screen. Fully motorized and automated, the testing process is free from operator influence, ensuring consistent results. Its intuitive operation makes it easy to use, even for entry-level operators.

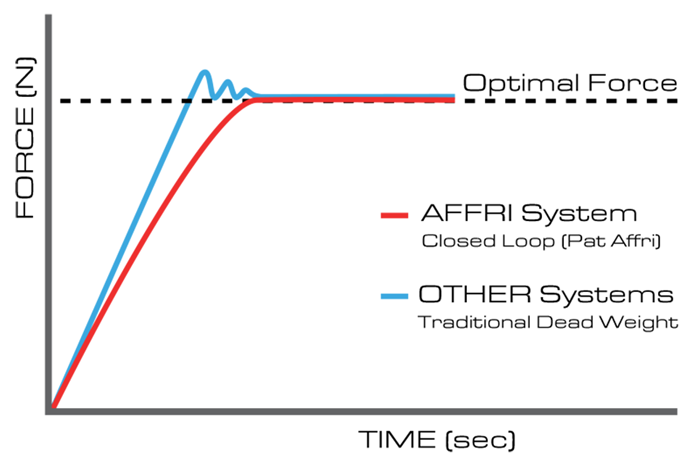

Load Cell and Closed-Loop System

Load forces are applied using load cells and are electronically managed in a ‘Closed-Loop’ system (AFFRI Patent) with a frequency of 1 kHz. Each load force is automatically programmed and precisely controlled, ensuring perfect linearity across all ranges and eliminating issues common with traditional deadweight testers.

Test results are unaffected by structural deflection, misalignment, or external vibrations. Highly accurate measurements are achieved from the very first test, removing the need for repeated testing. The precision of the first measurement guarantees reliability, with R&R (repeatability and reproducibility) performance setting a new benchmark in its class.

- The first test result is correct and absolute

- Save time and money

- Icrease your productivity

The right solution for Plastics and Rubbers materials

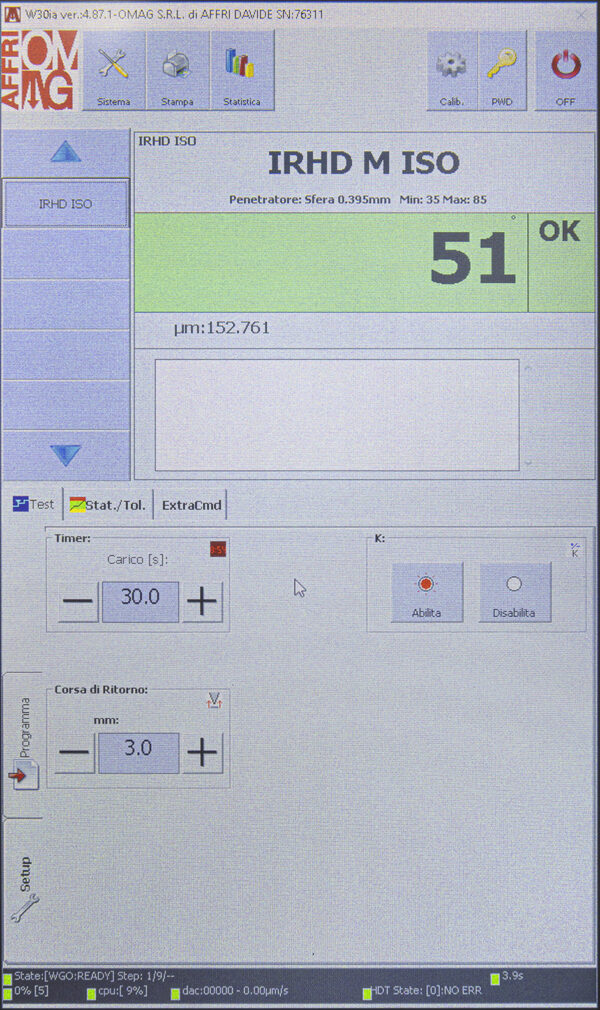

Software

AFFRI IRHD hardness tester features a 10.4” LCD touchscreen PC with USB and Ethernet ports, ensuring seamless connectivity to network devices, printers, and keyboards. It also supports remote service and assistance via internet connection. The integrated software manages the entire testing process, minimizing operator errors. Designed with user-friendliness in mind, the touchscreen interface makes operation intuitive and straightforward. The AFFRI software offers advanced analysis capabilities, including quick and simple test setup, live statistics, detailed graphs, and extensive data storage for test sessions.

Test Data Import and Export

Test cycles can be effortlessly loaded from a central system using a barcode scanner. The hardness tester processes all necessary information automatically. After the test is complete, the barcode data is updated with the results and instantly sent back to the order management system, streamlining the workflow and enhancing efficiency.