AFFRI MICRODAKO

Fully Motorized Multi-probe Hardness Tester for Plastics and Rubbers

AFFRI MICRODAKO is a fully motorized universal hardness tester that determines the hardness of any plastic and rubber material, in accordance with standardized methods IRHD and Shore. AFFRI MICRODAKO is equipped with 5 different hardness testing units mounted on a horizontally rotating turret.

Shore A – B – C – D – D0 – 0 – 00 – E – M – 000 – 000S

IRHD L – H – N – M

High-definition of 0.01 IRHD

ISO 48 – ASTM 1415

Test All Types of Plastics and Rubbers

AFFRI MICRODAKO features five distinct hardness testing units mounted on a horizontally rotating turret. Each unit is a dedicated probe for a specific hardness scale (Shore and IRHD). To switch between testing methods, simply rotate the turret to position the desired probe in front of the operator, the system automaticallyrecognizes the new setup and the testing sample surface.

The testing pressure and indentation movement occur along the same axis (Z), achieving a level of accuracy that surpasses standard manual testers. The system eliminates any sample movement, ensuring optimal stability throughout the entire test cycle.

The test cycle is fast and efficient: Thanks to the system’s precision, each test provides accurate results in a short amount of time. The turret is intuitive to control, allowing probe changes in just seconds.

Durable indenters: AFFRI-designed probes feature Tungsten Carbide indenters, ensuring long-lasting performance and consistent accuracy over time.

Universal Multi-probe IRHD and SHORE Hardness Tester

AFFRI MICRODAKO is a fully automated hardness tester designed to measure the hardness of various plastic and rubber materials, in full compliance with IRHD and Shore standardized methods. The multi-probe turret allows for rapid scale selection, streamlining the testing process. The system ensures automatic contact and measurement with the test sample from any starting position, with automatic loading controlled by a Closed-Loop system, achieving an impressive accuracy of 0.05%. Operator involvement is minimal, limited only to loading the sample onto the hardness tester’s working base.

Load forces can be easily selected through the PC interface and are applied automatically via electronically controlled load cells, operating in a Closed-Loop system (AFFRI Patent). MICRODAKO features a touchscreen PC interface and advanced software, providing complete control of the instrument from test configuration to full statistical management. The system can be customized with a variety of accessories based on specific customer needs.

L.I.S.A Laser Pointing System

The L.I.S.A. Laser Pointing System (AFFRI Patent) ensures precise test positioning, allowing accurate alignment before the indenter makes contact with the sample.

Fully Automatic Test Cycle

Simply press start, and the hardness tester will automatically carry out the entire testing cycle without missing any steps:

- Automatic approach and contact of the sample with the testing probe

- Secure clamping of the sample

- Measurement execution

- Sample release

Once the cycle is complete, the results are immediately displayed on the screen. Fully motorized and automated, the test is unaffected by operator influence, making it easy for entry-level users to operate. AFFRI MICRODAKO is a versatile laboratory instrument capable of testing a wide range of materials in various shapes and sizes. Each probe’s load force is managed by a highly calibrated dynamometric load cell, ensuring precise and consistent load application during every test.

Looking for a Smart Software?

This is a “SMART SOFTWARE” extremely easy to be used, studied to fulfil any user need and to be accessible to every operator

- TEST METHOD SELECTION A single window for all your testing needs. Easily select the hardness group, scale, and dwell time in one place.

- FULL HD 24" MONITOR Clear display of testing parameters, results, statistics, and all software features. Choose from 4 dynamic graphs that update in real-time with each hardness test.

- EASY RESULT MANAGEMENT Results are color-coded based on tolerance levels for easy identification. Modify, delete, or save individual or multiple tests. Create, save, or import test cycle sessions effortlessly.

- ONE-HAND FULL CONTROL Control the whole instrument with the mouse. Z axis motorization control with fast or slow speed. Clear and green START button.

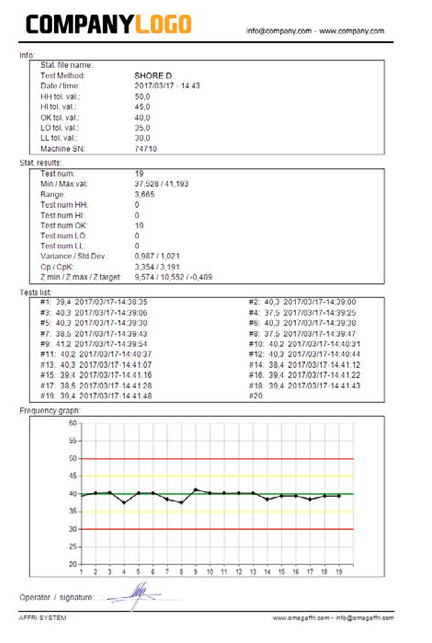

Fully Customizable Reporting

AFFRI provides custom-built report templates that can be adjusted to suit your exact specifications. You can easily incorporate your company logo and choose which test details appear in the layout. After completing a test, you can quickly select which data to include in the final report by toggling simple options.

Flexible Data Export

Easily print results directly from the AFFRI software or export your data in formats such as TXT, CSV, PDF, Word, Excel, or tabular format for further analysis with your preferred spreadsheet tools.

The system allows seamless loading of test cycles and sample details from a central database. The tester automatically gathers all relevant information, and once the test is finished, results are merged with the data and instantly transferred back to the order management system (MES).