AFFRI 3332 MRS

Automatic Rockwell hardness testers

- Test loads From 1 to 250 kgf (From 9,807 to 2452 N)

- Rockwell and superficial Rockwell ISO 6508 / ASTM E-18 HRA – HRB – HRC – HRD – HRF – HRG – HRL – HRM – HRR / HRN – HRT

- Brinell HBWT ISO 6506 / ASTM E-103 HB 30 – HB 10 – HB 5 – HB 2,5 – MPa (F/D2)

- Vickers ISO 6507 / ASTM E-92 (Indentation only) HV1 – HV3 – HV5 – HV10 – HV15 – HV20 – HV30 – HV50 – HV100

One touch measurement

The AFFRI System integrates fully automatic preloading, loading, and measurement procedures, offering the highest precision in depth accuracy and resolution for Rockwell hardness testing. The system ensures that real indentation measurements are obtained, eliminating external interference and guaranteeing consistent results under all conditions.

Key features include:

- Automatic contact initiation with the test specimen

- Automatic clamping and activation of the reference surface point

- Seamless preloading and loading processes

- Fully automated measurement

- Return stroke performed automatically at the set distance

Once the test cycle is completed, the results are promptly displayed. This advanced system ensures an effortless testing experience, with minimal operator intervention and maximum efficiency, making it ideal for high-precision hardness testing in various environments.

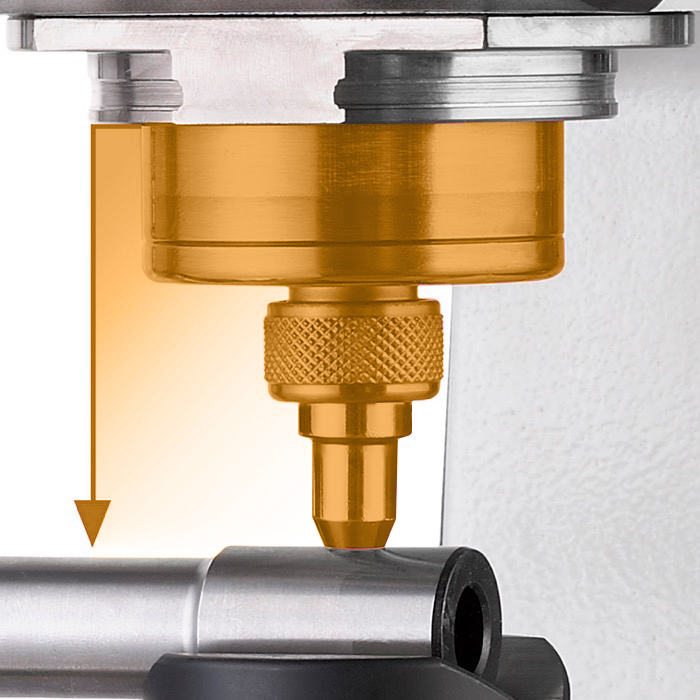

Auto-compensation of all deflections

Rockwell hardness testers in the MRS series feature a 50 mm independent stroke, which drives both the indenter and the clamping hood. This additional stroke operates independently from the head movement, providing enhanced functionality during testing. Throughout the testing process, the system maintains a constant pressure while the specimen is securely clamped. In cases where samples are unstable or prone to deflection, the measuring head automatically follows the movement of the sample, ensuring consistent contact.

This design is equipped with a top-surface referencing mechanism that minimizes errors associated with contaminants like dirt or scale, which often occur in traditional systems. As a result, sample preparation time is significantly reduced, leading to improvements in both measurement accuracy and testing speed.

Key advantages include:

- Accurate hardness testing on unstable or deflecting samples

- Automatic compensation for oil or dust buildup beneath the specimen

- Precise depth measurements even when the sample moves downwards during testing

- Safety auto-alarm system that triggers a stop if the sample becomes misaligned

- Self-compensation for any structural flexing that might impact test results

These features ensure that the MRS series testers provide highly reliable, accurate, and fast results, even in challenging testing conditions.

Closed-Loop invented by AFFRI

Closed-Loop Technology, pioneered by AFFRI, is an advanced method for applying load forces via precision load cells, regulated within a Closed-Loop System operating at a frequency of 1 kHz. This guarantees exceptional linearity across all ranges, ensuring highly accurate and consistent results. The measurement process remains unaffected by structural deflections, misalignment, or external vibrations, providing the utmost stability during testing. The Affri® System is engineered to deliver superior reliability and precision under any measurement conditions, ensuring that results are unaffected by external factors, whether they be physical, mechanical, or human-related.

Moreover, the system’s outstanding Repeatability and Reproducibility (R&R) capabilities set the AFFRI System apart as a leader in industrial innovation, making it a top choice for critical quality control processes. Whether in challenging environments or under demanding circumstances, the Closed-Loop technology ensures that the highest standards of accuracy are met consistently, driving operational efficiency and reducing testing variability across applications.

Control with a touch

3332 MRS hardness tester is equipped with an advanced LCD multicolor touchscreen, providing an intuitive interface for seamless test planning and real-time result display. This user-friendly device is designed to simplify the testing process with easily adjustable measurement parameters, comprehensive statistical tools, and efficient data storage. The software allows for quick selection of hardness scales, clearly presented through large, easy-to-read tabs. Additionally, the system provides immediate access to conversion scales, corrections for cylindrical samples, and calibration offsets, which are always visible for convenience.

Test results are conveniently categorized according to set tolerances, and they can be visualized in three distinct graph formats, enhancing analysis and decision-making. 3332 MRS hardness tester also allows users to create and store personalized test cycles, ensuring that specific requirements are met for each application. Multiple operators can use the system with their individual settings intact, as the software retains each user’s customized configuration. This makes the tester highly adaptable and efficient for use in varied industrial and laboratory environments, improving productivity and accuracy for every test cycle.

MAIN FEATURES

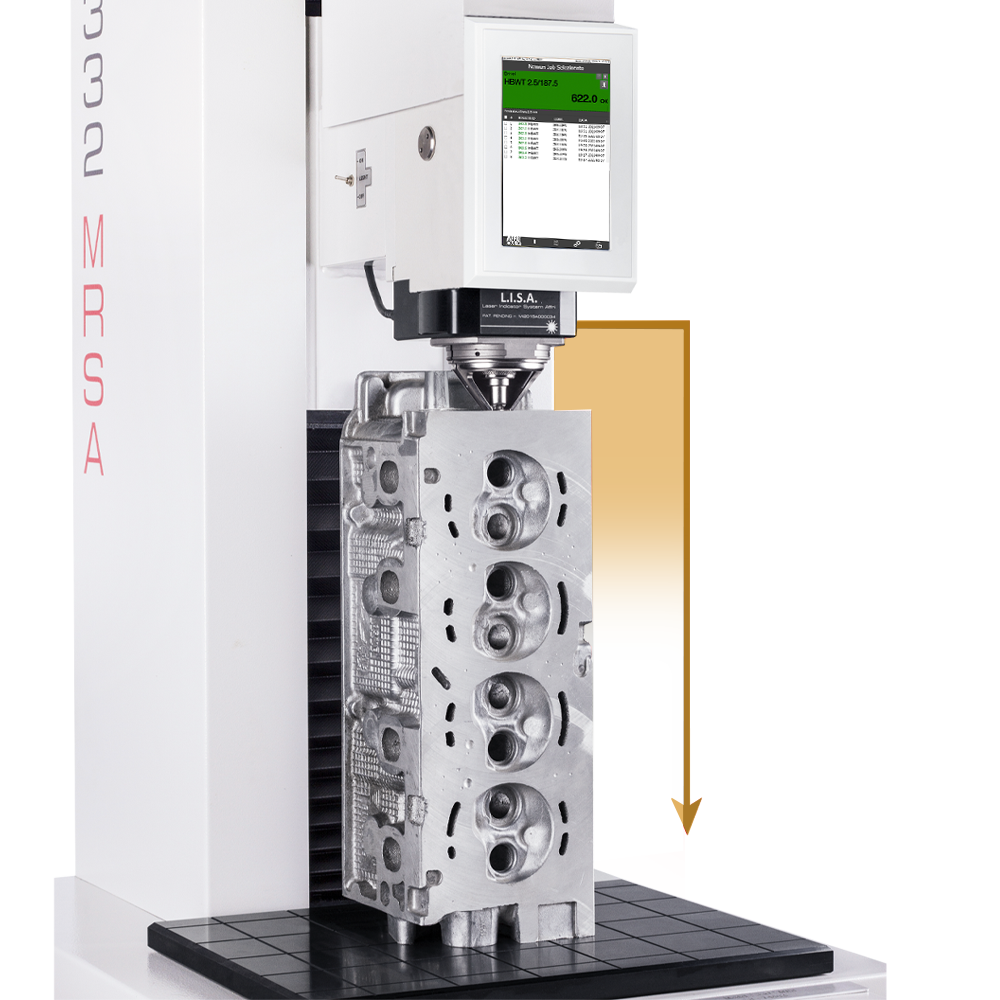

THE MOTORIZATION

The system features automated movement with an automatic stop upon contact with the sample. It offers a full 700 mm of motorized vertical travel. Unlike traditional systems where the sample moves towards the head, here the head approaches the specimen, resulting in more precise, stable, and secure measurements throughout the process.

MAIN FEATURES

THE CLAMPING (PAT. AFFRI)

A secure connection with the specimen is consistently ensured, even if there is any unexpected movement during the testing process. The clamping mechanism guarantees complete stability of the test piece throughout the entire testing cycle, regardless of whether the sample is oily, rusty, or contaminated.

MAIN FEATURES

HARD BASE

3332 MRS features a robust workbench with a wide base, capable of supporting loads exceeding 1000 kg. This provides stable hardness measurements on large or uneven samples while also offering a secure and convenient platform for testing smaller components.

EXTRA FEATURES

- L.I.S.A – Laser Indicator System Affri (Patented) Exclusive application which allows ultra-precise test positioning. The dual laser pointing system helps to define the indentation area and distance before the contact between the indenter and the specimen. Reach extreme points with lack of illumination, edges of gear’s teeth or sides of cutting tools and blades. (This application is optional)

- SAMPLE ILLUMINATION BY LED Adjustable LED light source for a clear view of the test zone on any surface or specimen shape. Illuminate extreme points where lighting is low like sample holes and dark layers. The adjustable arm of the light can be bent in any direction allowing illumination outside of the testing area. (LED light is optional)