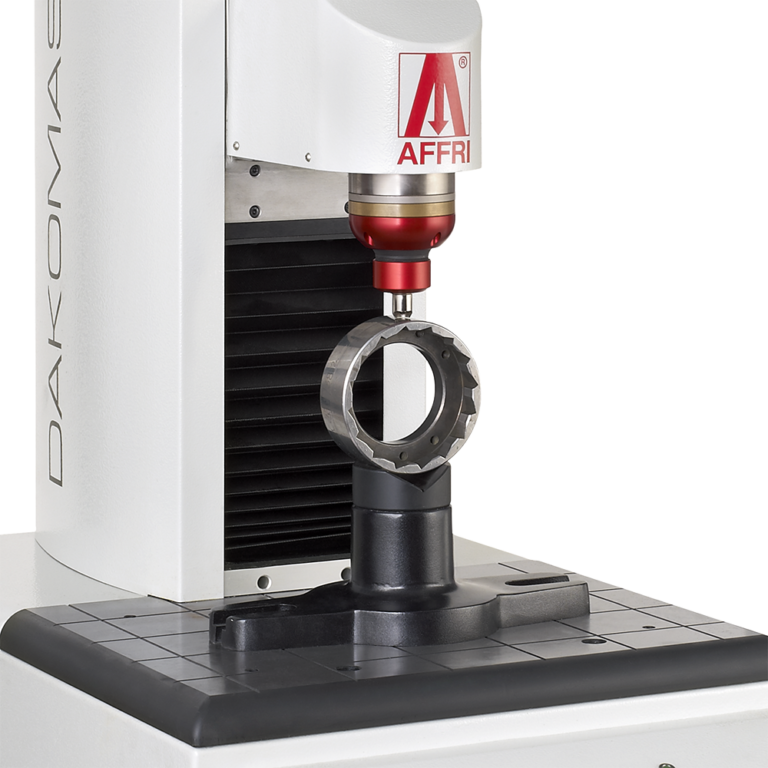

AFFRI DAKOMASTER 300

Motorized hardness testers for automatic cycle

AFFRI DAKOMASTER 300 is a Rockwell hardness tester with a fully automatic test cycle for Rockwell, Superficial Rockwell, Brinell, Vickers, and Shore tests. It complies with ASTM and ISO hardness standards. This hardness tester is a top-level bench model with a wide touchscreen, allowing easy test planning and a clear view of results.

- Test loads From 1 to 250 kgf (From 9,807 to 2452 N)

- Rockwell and superficial Rockwell ISO 6508 / ASTM E-18 HRA – HRB – HRC – HRD – HRF – HRG – HRL – HRM – HRR / HRN – HRT

- Brinell HBWT ASTM E-103 / ISO 6506 HB 30 – HB 10 – HB 5 – HB 2,5 – MPa (F/D2)

- Vickers ISO 6507 / ASTM E-92 (Indentation only) HV1 – HV3 – HV5 – HV10 – HV15 – HV20 – HV30 – HV50 – HV100

ONE TOUCH MEASUREMENT

- The system establishes contact with the specimen

- It automatically clamps and activates the reference surface point

- Preloading, loading, and measurement occur seamlessly

- The sample is released and the return stroke is completed at the programmed distance

The entire cycle completes automatically, and the result is displayed instantly.

Dakomaster paired with the Affri System delivers unparalleled precision and reliability.

As with all Affri hardness testers, this system achieves the highest level of depth accuracy, ensuring the most precise Rockwell test measurements available. This guarantees accurate indentation readings free from any external interference, regardless of test conditions.

AUTOMATIC VERTICAL STROKE OF MEASURING HEAD

DAKOMASTER 300 features automated movement, automatically halting upon contact with the sample, safeguarding both the specimen and the operator. Its 300 mm motorized vertical stroke ensures precise and effortless testing across a wide range of sample sizes.

A key advantage of this model is that the sensor moves toward the sample, as opposed to relocating the sample to the sensor. This approach enhances stability, precision, and safety throughout the testing process. Perfect for both industrial environments and laboratory settings, DAKOMASTER 300 delivers consistent, reliable performance, ensuring accurate quality control and hardness measurement in compliance with Rockwell standards.

AUTO-COMPENSATION SYSTEM OF DEFLECTIONS

When testing unstable or deforming samples, the AFFRI System ensures continuous and reliable contact by adapting seamlessly to the sample’s movement. Thanks to its infinite stroke for both the indenter and clamping hood, the system remains in perfect alignment, maintaining measurement accuracy even for parts that shift or flex during testing. Load forces are meticulously managed through advanced load cells, controlled within a “Closed Loop” system operating at a high frequency of 1 kHz. This process ensures absolute linearity in every range, effectively preventing any external interference such as structural deflection, misalignment, or vibrations from impacting the results. With the AFFRI System, accurate and repeatable measurements are achieved on the very first test, even under extreme testing conditions, which significantly reduces the need for redundant measurements. Furthermore, the system provides top-tier repeatability and reproducibility (R&R) data, placing it at the forefront of precision in hardness testing technology across various industries.

SOFTWARE

This advanced Rockwell hardness tester comes with pre-installed software that seamlessly manages the entire testing process, ensuring accurate results while minimizing the potential for operator error. Dakomaster’s software suite offers a comprehensive set of features to streamline the testing process and enhance overall efficiency.

Key features include:

- A large 10/12″ touchscreen display for easy navigation and control.

- User-friendly software developed by AFFRI for intuitive operation.

- Color-coded results indicating low, acceptable, or high hardness levels for instant interpretation.

- Real-time statistics and graphical displays for continuous monitoring of test progress.

- Configurable test programs for customizable testing conditions.

- Comprehensive results archiving to track historical data and trends.

- Capability to export results in multiple formats including PDF, TXT, CSV, DOD, XLS, and more for seamless data integration.

- Barcode scanning for quick and accurate data entry, ensuring enhanced traceability.

- Multiple output options such as RS232, USB, and Ethernet for flexible connectivity.

- Direct data exchange with the MES (Management Execution System) for real-time integration into the broader production workflow.

- Remote import of measurement settings to enable remote configuration and updates.

- Seamless network integration for streamlined communication with other systems.

These features make Dakomaster an ideal choice for modern industrial environments, optimizing productivity, enhancing precision, and ensuring flawless integration with other automated systems.

AUTOMATIC ENGAGEMENT

The system features automated movement with an automatic stop once contact is established with the sample. It offers a 300 mm vertical stroke powered by a motor for seamless operation. The unique design, where the head moves towards the specimen instead of the specimen being moved towards the head, ensures more precise, stable, and secure measurements.

COMPACT HEAD

DAKOMASTER 300 Rockwell hardness tester features a compact and streamlined measuring head, enabling it to easily perform tests within tubes with diameters of 150 mm or larger. Its slim clamping hood design allows for testing in tight spaces, ensuring precise positioning even in confined areas.

OPEN SPACE

The Rockwell hardness tester is equipped with a large, sturdy work table base that can support weights exceeding 2000 kg, ensuring stable hardness measurements on large or irregularly shaped components. Additionally, it provides a secure and convenient platform for testing smaller pieces.

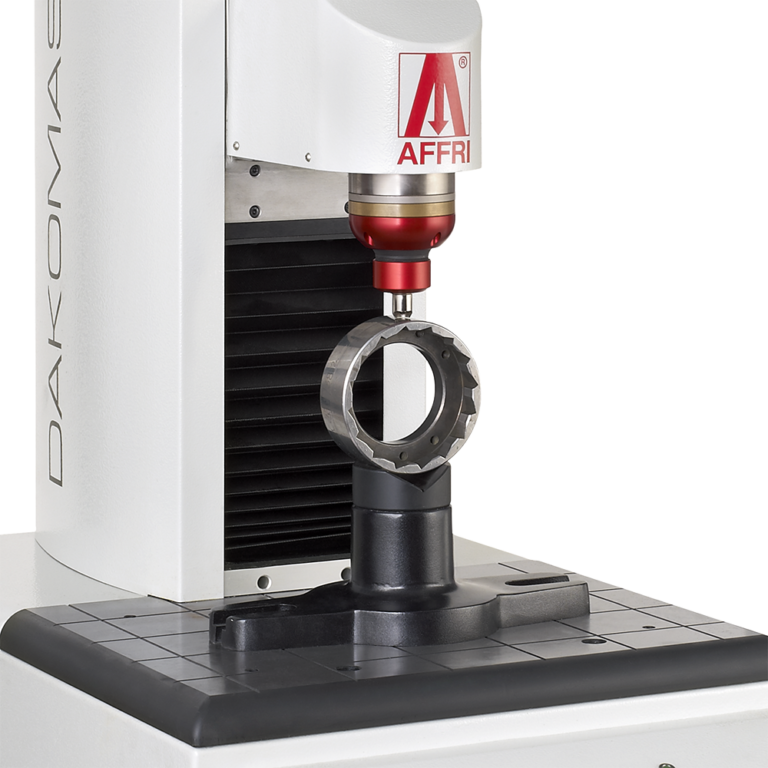

AFFRI DAKOMASTER 300

Motorized hardness testers for automatic hardness test cycle

AFFRI DAKOMASTER 300 is a Rockwell hardness tester with a fully automatic test cycle for Rockwell, Superficial Rockwell, Brinell, Vickers, and Shore tests. It complies with ASTM and ISO hardness standards. This hardness tester is a top-level bench model with a wide touchscreen, allowing easy test planning and a clear view of results.

- Test loads From 1 to 250 kgf (From 9,807 to 2452 N)

- Rockwell and superficial Rockwell ISO 6508 / ASTM E-18 HRA – HRB – HRC – HRD – HRF – HRG – HRL – HRM – HRR / HRN – HRT

- Brinell HBWT ASTM E-103 / ISO 6506 HB 30 – HB 10 – HB 5 – HB 2,5 – MPa (F/D2)

- Vickers ISO 6507 / ASTM E-92 (Indentation only) HV1 – HV3 – HV5 – HV10 – HV15 – HV20 – HV30 – HV50 – HV100

ONE BUTTON MEASUREMENT

- The system establishes contact with the specimen

- It automatically clamps and activates the reference surface point

- Preloading, loading, and measurement occur seamlessly

- The sample is released and the return stroke is completed at the programmed distance

The entire cycle completes automatically, and the result is displayed instantly.

Dakomaster paired with the Affri System delivers unparalleled precision and reliability.

As with all Affri hardness testers, this system achieves the highest level of depth accuracy, ensuring the most precise Rockwell test measurements available. This guarantees accurate indentation readings free from any external interference, regardless of test conditions.

AUTOMATIC VERTICAL STROKE OF MEASURING HEAD

DAKOMASTER 300 features automated movement, automatically halting upon contact with the sample, safeguarding both the specimen and the operator. Its 300 mm motorized vertical stroke ensures precise and effortless testing across a wide range of sample sizes.

A key advantage of this model is that the sensor moves toward the sample, as opposed to relocating the sample to the sensor. This approach enhances stability, precision, and safety throughout the testing process. Perfect for both industrial environments and laboratory settings, DAKOMASTER 300 delivers consistent, reliable performance, ensuring accurate quality control and hardness measurement in compliance with Rockwell standards.

AUTO-COMPENSATION SYSTEM OF DEFLECTIONS

When testing unstable or deforming samples, the AFFRI System ensures continuous and reliable contact by adapting seamlessly to the sample’s movement. Thanks to its infinite stroke for both the indenter and clamping hood, the system remains in perfect alignment, maintaining measurement accuracy even for parts that shift or flex during testing. Load forces are meticulously managed through advanced load cells, controlled within a “Closed Loop” system operating at a high frequency of 1 kHz. This process ensures absolute linearity in every range, effectively preventing any external interference such as structural deflection, misalignment, or vibrations from impacting the results. With the AFFRI System, accurate and repeatable measurements are achieved on the very first test, even under extreme testing conditions, which significantly reduces the need for redundant measurements. Furthermore, the system provides top-tier repeatability and reproducibility (R&R) data, placing it at the forefront of precision in hardness testing technology across various industries.

SOFTWARE

This advanced Rockwell hardness tester comes with pre-installed software that seamlessly manages the entire testing process, ensuring accurate results while minimizing the potential for operator error. Dakomaster’s software suite offers a comprehensive set of features to streamline the testing process and enhance overall efficiency.

Key features include:

A large 10/12″ touchscreen display for easy navigation and control.

User-friendly software developed by AFFRI for intuitive operation.

Color-coded results indicating low, acceptable, or high hardness levels for instant interpretation.

Real-time statistics and graphical displays for continuous monitoring of test progress.

Configurable test programs for customizable testing conditions.

Comprehensive results archiving to track historical data and trends.

Capability to export results in multiple formats including PDF, TXT, CSV, DOD, XLS, and more for seamless data integration.

Barcode scanning for quick and accurate data entry, ensuring enhanced traceability.

Multiple output options such as RS232, USB, and Ethernet for flexible connectivity.

Direct data exchange with the MES (Management Execution System) for real-time integration into the broader production workflow.

Remote import of measurement settings to enable remote configuration and updates.

Seamless network integration for streamlined communication with other systems.

These features make Dakomaster an ideal choice for modern industrial environments, optimizing productivity, enhancing precision, and ensuring flawless integration with other automated systems.

MAIN FEATURES

AUTOMATIC ENGAGEMENT

The system features automated movement with an automatic stop once contact is established with the sample. It offers a 300 mm vertical stroke powered by a motor for seamless operation. The unique design, where the head moves towards the specimen instead of the specimen being moved towards the head, ensures more precise, stable, and secure measurements.

OPEN SPACE

The Rockwell hardness tester is equipped with a large, sturdy work table base that can support weights exceeding 2000 kg, ensuring stable hardness measurements on large or irregularly shaped components. Additionally, it provides a secure and convenient platform for testing smaller pieces.

COMPACT HEAD

DAKOMASTER 300 Rockwell hardness tester features a compact and streamlined measuring head, enabling it to easily perform tests within tubes with diameters of 150 mm or larger. Its slim clamping hood design allows for testing in tight spaces, ensuring precise positioning even in confined areas.