MASTER HARDNESS TEST BLOCKS

We provide high-precision master hardness test blocks for every hardness scale, including ILAC MRA certification by ANAB ISO/IEC 17025, to ensure daily and continuous accuracy on your hardness testers. They are available in all Rockwell, Brinell, Vickers, and Knoop scales. Choose AFFRI Inc. for precise, certified specimens that meet the highest standards.

CERTIFICATE NUMBER: AC-3026

MASTER HARDNESS TEST BLOCKS

We provide high-precision master hardness test blocks for every hardness scale, including ILAC MRA certification by ANAB ISO/IEC 17025, to ensure daily and continuous accuracy on your hardness testers. They are available in all Rockwell, Brinell, Vickers, and Knoop scales. Choose AFFRI Inc. for precise, certified specimens that meet the highest standards.

CERTIFICATE NUMBER: AC-3026

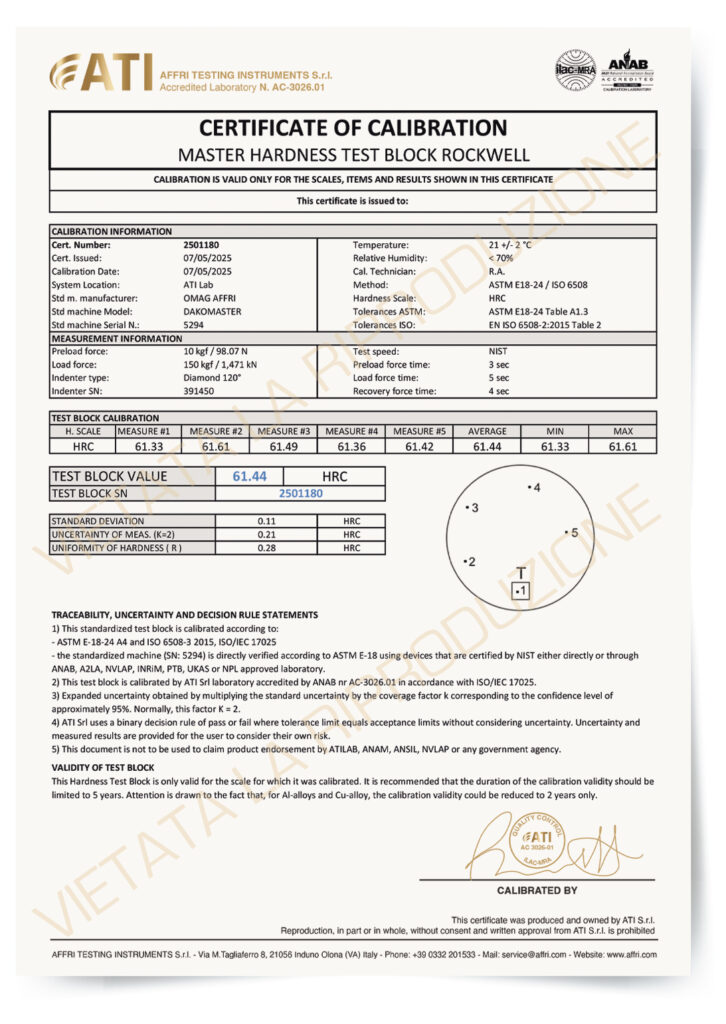

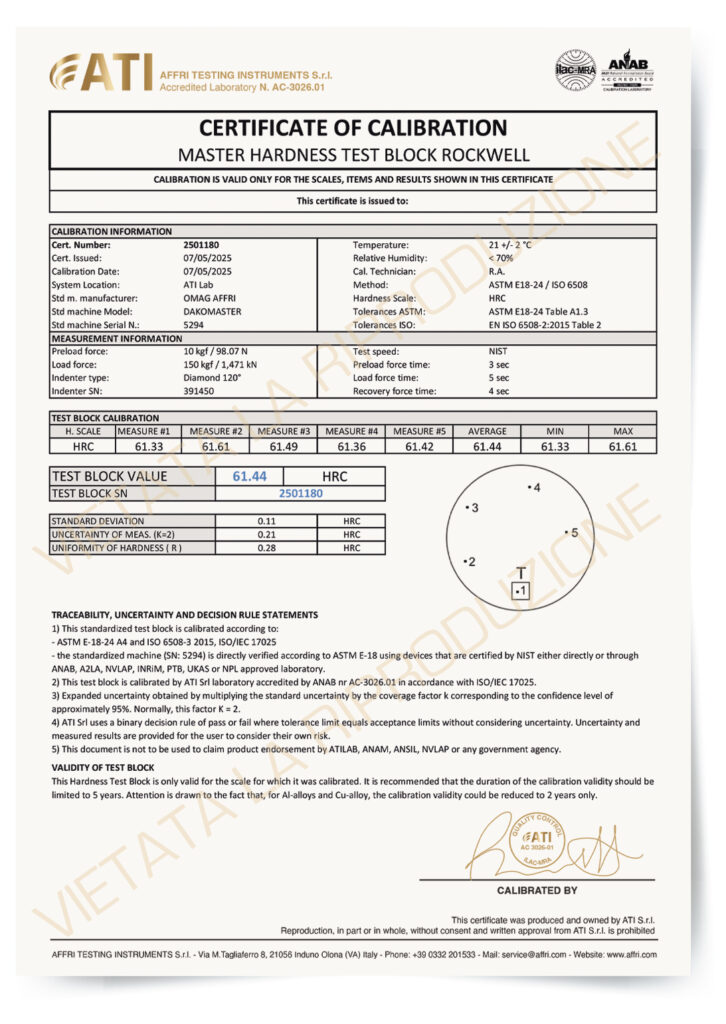

Certified Precision Master Test Blocks for Hardness Instrument Calibration

ATI Laboratory Accredited ISO/IEC 17025

Affri Testing Instruments Laboratory is ANAB ISO/IEC 17025 accredited with certificate no. AC 3026, and offers high-precision certified test blocks for the calibration and verification of hardness testers, ensuring full compliance with international ISO and ASTM standards. Our certified test blocks cover all hardness scales, including Rockwell, Brinell, Vickers, and Knoop, and are available in a wide range of values to meet the diverse calibration needs of our customers.

Rockwell

- Rockwell

| Hardness Scale | Hardness Range | Size mm with mirror surface | Weight |

|---|---|---|---|

| HRA | < 70 | Ø 60X10 mm | 0,35 kg |

| ≥ 70 and < 80 | Ø 60X10 mm | 0,35 kg | |

| ≥ 80 | Ø 60X10 mm | 0,35 kg | |

| HRB | < 60 | Ø 60X10 mm | 0,35 kg |

| ≥ 60 and < 88 | Ø 60X10 mm | 0,35 kg | |

| ≥ 88 | Ø 60X10 mm | 0,35 kg | |

| HRC | < 35 | Ø 60X10 mm | 0,35 kg |

| ≥ 35 and < 60 | Ø 60X10 mm | 0,35 kg | |

| ≥ 60 | Ø 60X10 mm | 0,35 kg | |

| HRD | < 51 | Ø 60X10 mm | 0,35 kg |

| ≥ 51 and < 71 | Ø 60X10 mm | 0,35 kg | |

| ≥ 71 | Ø 60X10 mm | 0,35 kg | |

| HRE | < 84 | Ø 60X10 mm | 0,35 kg |

| ≥ 84 and < 93 | Ø 60X10 mm | 0,35 kg | |

| ≥ 93 | Ø 60X10 mm | 0,35 kg | |

| HRF | < 80 | Ø 60X10 mm | 0,35 kg |

| ≥ 80 and < 94 | Ø 60X10 mm | 0,35 kg | |

| ≥ 94 | Ø 60X10 mm | 0,35 kg | |

| HR15N | < 78 | Ø 60X10 mm | 0,35 kg |

| ≥ 78 and < 90 | Ø 60X10 mm | 0,35 kg | |

| ≥ 90 | Ø 60X10 mm | 0,35 kg | |

| HR30N | < 55 | Ø 60X10 mm | 0,35 kg |

| ≥ 55 and < 77 | Ø 60X10 mm | 0,35 kg | |

| ≥ 77 | Ø 60X10 mm | 0,35 kg | |

| HR45N | < 37 | Ø 60X10 mm | 0,35 kg |

| ≥ 37 and < 66 | Ø 60X10 mm | 0,35 kg | |

| ≥ 66 | Ø 60X10 mm | 0,35 kg | |

| HR15T | < 81 | Ø 60X10 mm | 0,35 kg |

| ≥ 81 and < 87 | Ø 60X10 mm | 0,35 kg | |

| ≥ 87 | Ø 60X10 mm | 0,35 kg | |

| HR30T | < 57 | Ø 60X10 mm | 0,35 kg |

| ≥ 57 and < 70 | Ø 60X10 mm | 0,35 kg | |

| ≥ 70 | Ø 60X10 mm | 0,35 kg | |

| HR45T | < 33 | Ø 60X10 mm | 0,35 kg |

| ≥ 33 and < 53 | Ø 60X10 mm | 0,35 kg | |

| ≥ 53 | Ø 60X10 mm | 0,35 kg |

Brinell

- Brinell

| Hardness Scale | Hardness Range | Size mm with mirror surface | Weight |

|---|---|---|---|

| HBW 10/3000 | 95.5 to 650 | Ø 90X17 mm | 1 kg |

| HBW 10/1500 | 47.7 to 327 | Ø 90X17 mm | 1 kg |

| HBW 10/1000 | 31.8 to 218 | Ø 90X17 mm | 1 kg |

| HBW 10/500 | 15.9 to 109 | Ø 90X17 mm | 1 kg |

| HBW 10/250 | 7.96 to 54.5 | Ø 60X10 mm | 0,35 kg |

| HBW 10/100 | 3.18 to 21.8 | Ø 60X10 mm | 0,35 kg |

| HBW 5/750 | 95.5 to 650 | Ø 60X10 mm | 1 kg |

| HBW 5/250 | 31.8 to 218 | Ø 60X10 mm | 0,35 kg |

| HBW 5/125 | 15.9 to 109 | Ø 60X10 mm | 0,35 kg |

| HBW 5/62,5 | 7.96 to 54.5 | Ø 60X10 mm | 0,35 kg |

| HBW 5/25 | 3.18 to 21.8 | Ø 60X10 mm | 0,35 kg |

| HBW 2.5/187.5 | 95.5 to 650 | Ø 60X10 mm | 0,35 kg |

| HBW 2.5/62.5 | 31.8 to 218 | Ø 60X10 mm | 0,35 kg |

Vickers

- Vickers

| Hardness Scale | Hardness Range | Size mm with mirror surface | Weight |

|---|---|---|---|

| HV2 | From 200 to 750 | Ø 60X10 mm | 0,35 kg |

| HV3 | From 200 to 750 | Ø 60X10 mm | 0,35 kg |

| HV5 | From 175 to 750 | Ø 60X10 mm | 0,35 kg |

| HV10 | From 175 to 750 | Ø 60X10 mm | 0,35 kg |

| HV20 | From 175 to 750 | Ø 60X10 mm | 0,35 kg |

| HV30 | From 175 to 750 | Ø 60X10 mm | 0,35 kg |

| HV50 | From 175 to 750 | Ø 60X10 mm | 0,35 kg |

| HV100 | From 175 to 750 | Ø 60X10 mm | 0,35 kg |

Micro Vickers

- Micro Vickers

| Hardness Scale | Hardness Range | Size mm with mirror surface | Weight |

|---|---|---|---|

| HV0.01 | From 200 to 750 | Ø 25X10 mm | 0,4 kg |

| HV0.015 | From 200 to 750 | Ø 25X10 mm | 0,4 kg |

| HV0.02 | From 200 to 750 | Ø 25X10 mm | 0,4 kg |

| HV0.025 | From 200 to 750 | Ø 25X10 mm | 0,4 kg |

| HV0.05 | From 200 to 750 | Ø 25X10 mm | 0,4 kg |

| HV0.1 | From 200 to 750 | Ø 25X10 mm | 0,4 kg |

| HV0.2 | From 200 to 750 | Ø 25X10 mm | 0,4 kg |

| HV0.3 | From 200 to 750 | Ø 25X10 mm | 0,4 kg |

| HV0.5 | From 200 to 750 | Ø 25X10 mm | 0,4 kg |

| HV1 | From 200 to 750 | Ø 25X10 mm | 0,4 kg |

Knoop

- Knoop

| Hardness Scale | Hardness Range | Size mm with mirror surface | Weight |

|---|---|---|---|

| HK0.01 | From 200 to 750 | Ø 25X10 mm | 0,4 kg |

| HK0.02 | From 200 to 750 | Ø 25X10 mm | 0,4 kg |

| HK0.025 | From 200 to 750 | Ø 25X10 mm | 0,4 kg |

| HK0.05 | From 200 to 750 | Ø 25X10 mm | 0,4 kg |

| HK0.1 | From 200 to 750 | Ø 25X10 mm | 0,4 kg |

| HK0.2 | From 200 to 750 | Ø 25X10 mm | 0,4 kg |

| HK0.3 | From 200 to 750 | Ø 25X10 mm | 0,4 kg |

| HK0.5 | From 200 to 750 | Ø 25X10 mm | 0,4 kg |

| HK1 | From 200 to 750 | Ø 25X10 mm | 0,4 kg |

| HK2 | From 200 to 750 | Ø 25X10 mm | 0,4 kg |

When Should a Hardness Test Block Be Used?

These blocks are essential in several scenarios, including:

Routine checks before using a hardness tester each day

Scheduled calibrations carried out by accredited labs

After servicing, adjustments, or relocation of the testing machine

To ensure consistent results between different operators or instruments

When Is a Certified Block Required?

Using a certified hardness block is mandatory in the following cases:

When compliance with ISO/IEC 17025, ISO, or ASTM standards is needed

During internal audits or third-party inspections

In industries that require traceable test data (such as aerospace, medical, or automotive)

If the hardness tester hasn’t been verified recently or has undergone changes

Best Practices for Maintaining Test Blocks

To extend the life and reliability of your test blocks:

Distribute tests across the surface to avoid repeated impressions in one area

Store blocks in protective cases, away from dust and moisture

Clean with alcohol or a lint-free cloth to prevent contamination

Avoid contact with oil, dirt, or residue from test samples

Replace blocks when worn or visibly deformed

Schedule recalibration annually or according to your internal quality system