ULTRARAPID INCLUSION RATING

Clemex CIR helps quality control laboratories vastly improve their productivity by analyzing inclusion in steel with impressive speed, accuracy and repeatability. Very easy to operate, the inclusion rating software will always you to reduce analysis time to less than 3 minutes for a 160 mm2 area with minimal user intervention.

TYPE ON ANALYSIS

Our automated image analysis system is designed to detect the following inclusions and rate them according to most recognized standards: sulfides, aluminates, silicates, globular oxides, single globulars, borides, carbides, nitrides, and carbonitrides.

ASTM E45 Methods A, C, D, E

Standard Test Methods for Determining the Inclusion Content of Steel

ISO 4967 Methods A, B

Steel – Determination of content of non-metallic inclusions – Micrographic method using standard diagrams

DIN 50602 Methods M, K

Metallographic examination; microscopic examination of special steels using standard diagrams to assess the content of non-metallic inclusions

JIS G 0555

Microscopic testing method for the non-metallic inclusions in steel

EN 10247

Micrographic examination of the non-metallic inclusion content of steels using standard pictures

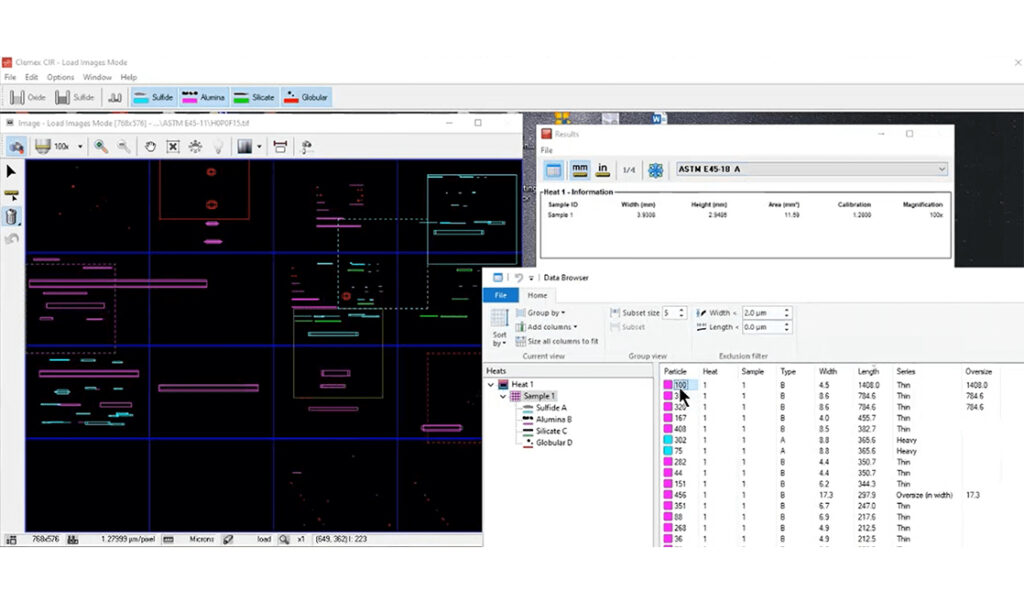

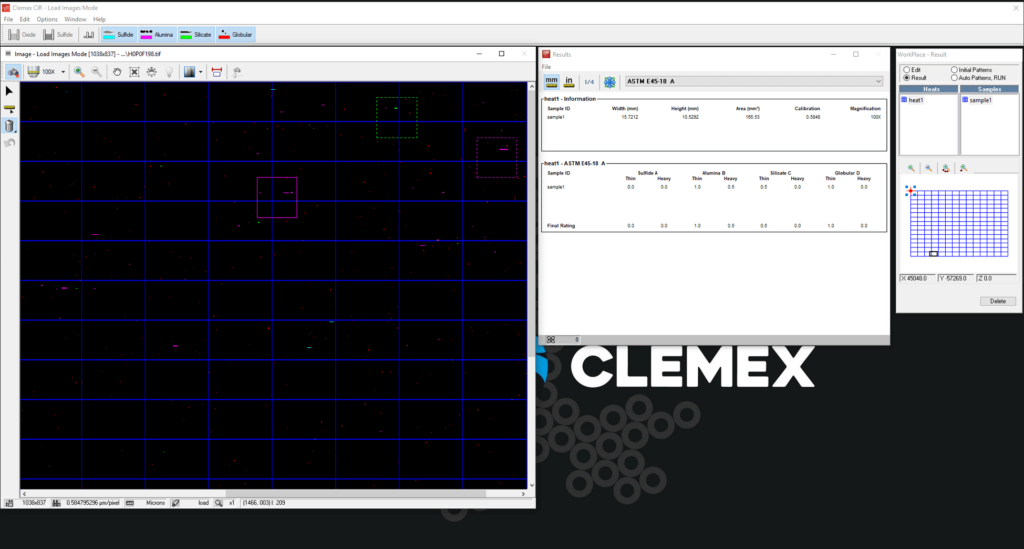

EASY DATA SORTING

Take advantage of the most efficient data browser on the market. All detected inclusions can be sorted, filtered and validated within seconds allowing you to focus on critical data.

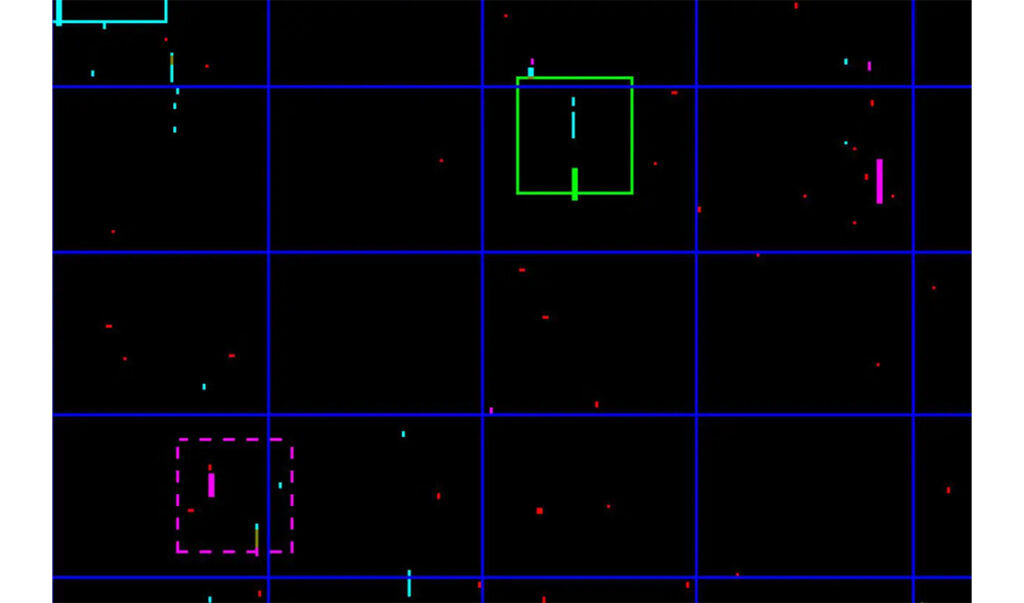

MAP OF ENTIRE SAMPLE

Locates and maps inclusions of the entire sample area, aligned vertically or horizontally. Worst fields are identified rapidly and artifacts can be removed. Operators navigate from one sample to the other with ease.

TRACEABLE OBJECTS

Select inclusions and artifacts on a map of the entire sample. Toggle between this map view and the selected objects to accept, reclassify or reject them.

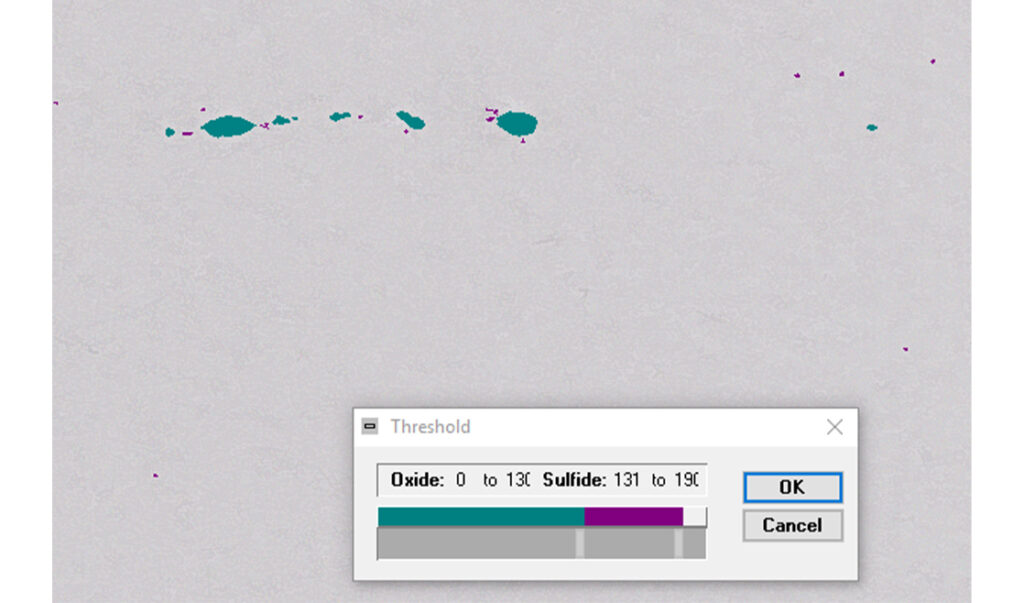

CLASSIFY OXIDES AND SULFIDES

Adjust the thresholding to detect oxides and sulfides accurately. Eliminate fine artifacts and scratches.

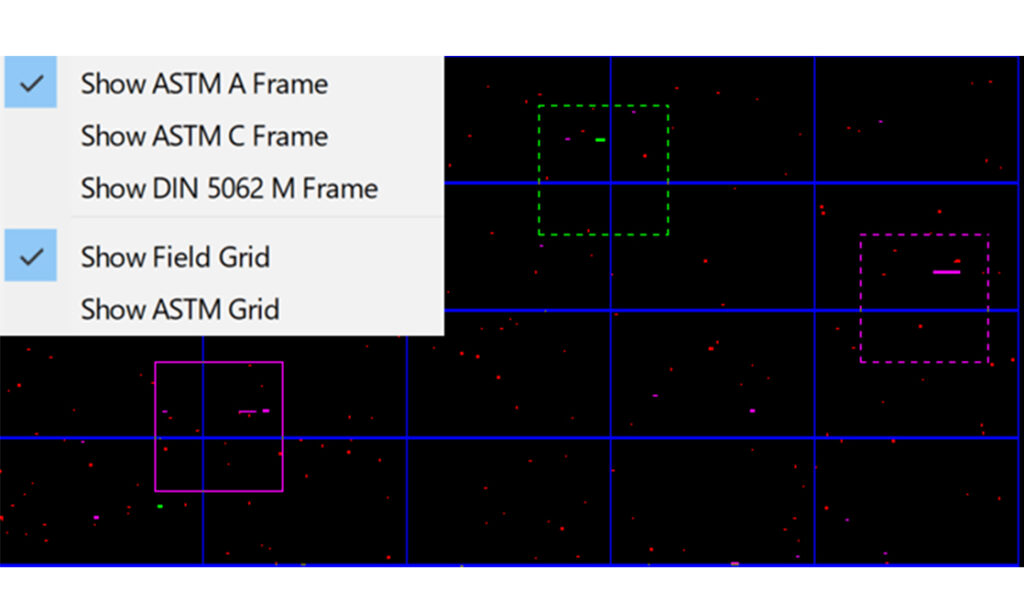

FLOATING WORST FIELDS

ASTM, ISO or DIN worst fields are identified automatically. Worst fields are displayed on the sample map using colors that correspond to inclusion types.

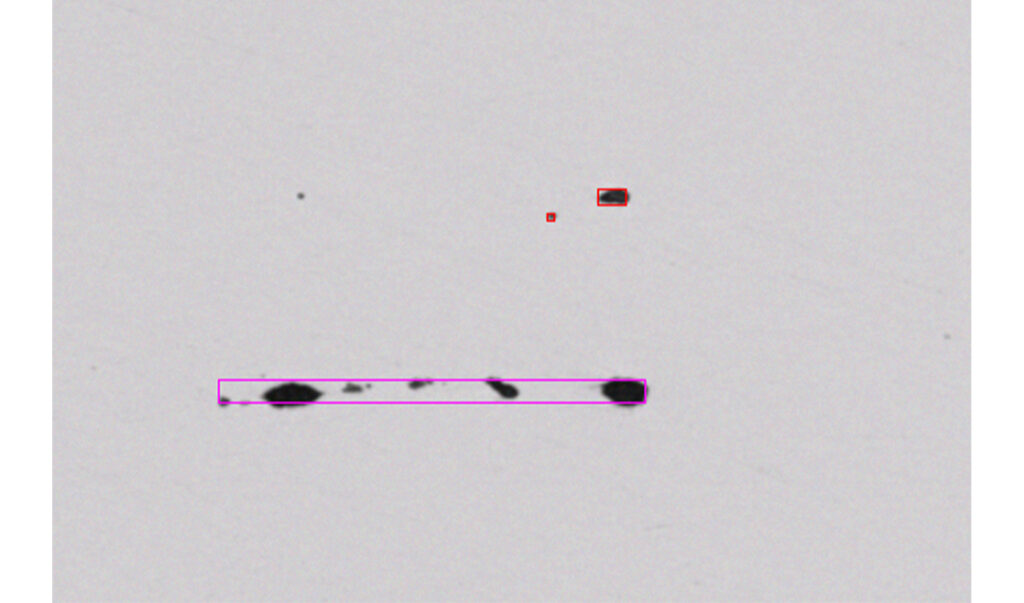

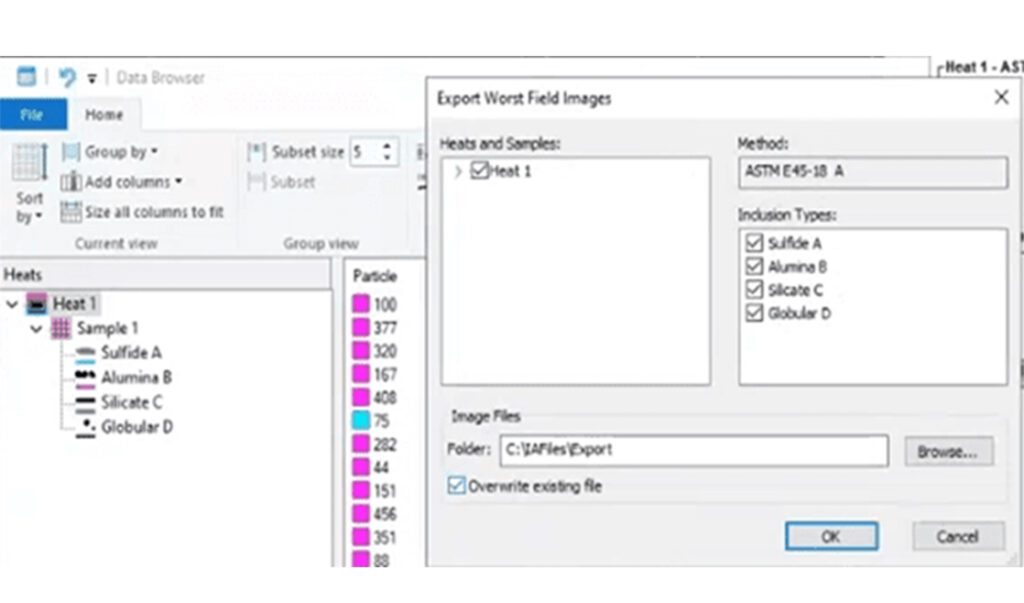

SAVE IMAGES OF WORST FIELD

Automatically export worst field .tiff images showing detection. This greatly saves time when creating reports for the ASTM E-45 Method A standard.

PRODUCTS DETAILS

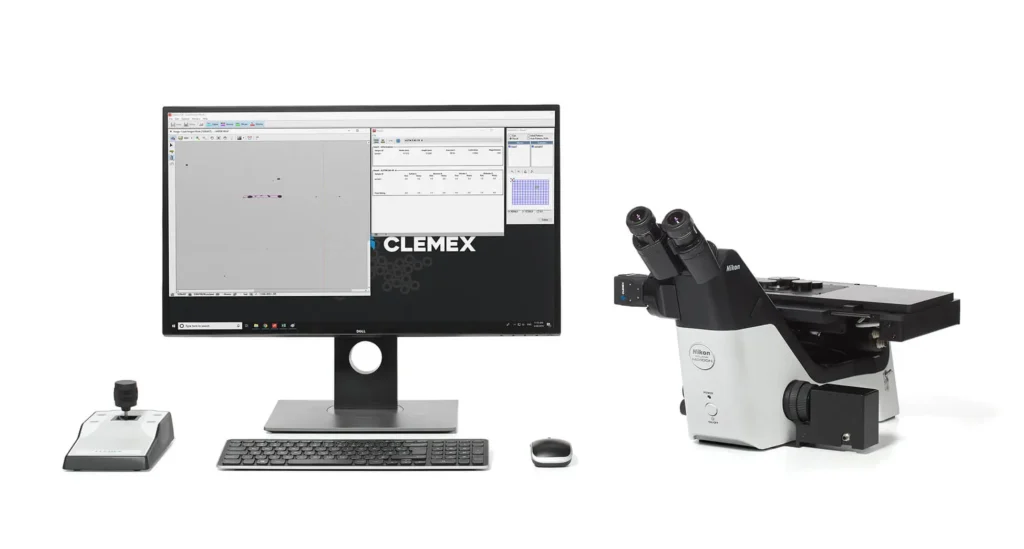

Typically, an inverted Nikon microscope, a motorized Marzhauser stage, and a high resolution camera are selected to fit your specific inclusion rating needs. We ensure a seamless integration of all components.

- Analysis of your needs by a technical representative

- Configuration, fine-tuning, and calibration

- On-site installation and training of your team

Increase productivity in a high throughput lab using a very simple workflow. The operator follows a 3-step procedure to obtain repeatable results:

- Position a sample on the stage

- Start an analysis on the sample

- Review data and export results