AFFRI 250 DRM

Motorized Rockwell Hardness Tester

AFFRI 250 DRM Rockwell Hardness Tester is a semi-automatic, user-friendly device designed for precise hardness testing across various scales, including HRC, HRB, HRA, and other specialized scales, with test loads ranging from 3 to 250 kgf. This versatile tester is capable of performing Rockwell, Superficial Rockwell, and Brinell HBWT hardness tests. It is fully compliant with all relevant international hardness testing standards, such as ASTM E10 – E18 and ISO 6506 – 6508, ensuring accurate and reliable results for a wide range of materials.

- Test loads from 3 to 250 kgf (From 29,42 to 2452 N)

- Rockwell and superficial Rockwell ISO 6508 / ASTM E-18 HRA – HRB – HRC – HRD – HRF – HRG – HRL – HRM – HRR / HRN – HRT

- Brinell HBWT ASTM E-103 / ISO 6506 HB 30 – HB 10 – HB 5 – HB 2,5 – MPa (F/D2)

- Vickers ISO 6507 / ASTM E-92 (Indentation only) HV3 – HV5 – HV10 – HV15 – HV20 – HV30 – HV50 – HV100

AUTOMATIC HARDNESS TESTER

250 DRM is a fast and exceptionally easy-to-use bench hardness tester that meets high-accuracy standards. To begin testing, simply adjust the elevating screw to bring the sample into contact with the indenter. Then, press the start button to automatically initiate the preloading and loading process. Within moments, the results are displayed on the screen. Load forces are applied electronically via load cells, eliminating the issues commonly associated with traditional dead-weight systems. This advanced system is unaffected by external vibrations and doesn’t require leveling, ensuring consistent performance in a variety of environments. The intuitive design allows operators of any experience level to perform tests efficiently. With its reliable operation, quick setup, and minimal maintenance, the 250 DRM is ideal for precise hardness testing in both laboratory and industrial settings, providing fast, accurate results every time.

MAIN CONTROL PANEL

Allows for the selection of various hardness scales, adjustment of dwell time, and management of conversion data. Features include a return stroke function, result memory and storage, statistical analysis, and the measurement of test temperature. The system supports calibration and self-diagnostics for routine checkups. It offers configurable tolerance limits, in-process averaging of results, and compensation for measurements on curved surfaces. Automatic evaluation of test outcomes ensures precise and consistent measurements. This suite of advanced functionalities enhances the accuracy, efficiency, and reliability of the testing process across diverse applications.

Only 3″ for one hardness test! (more with standardized dwell time)

EXTRA FEATURES

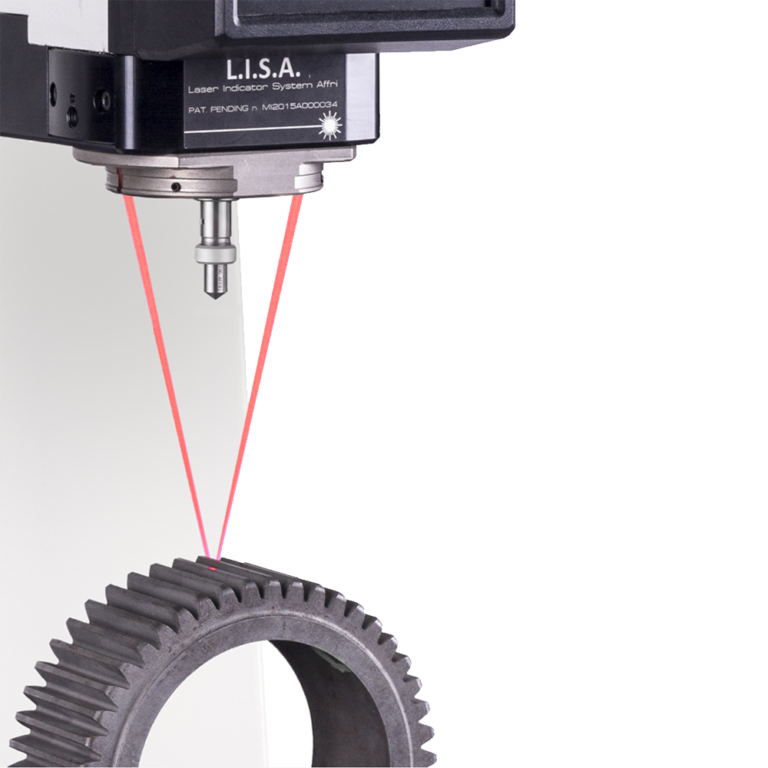

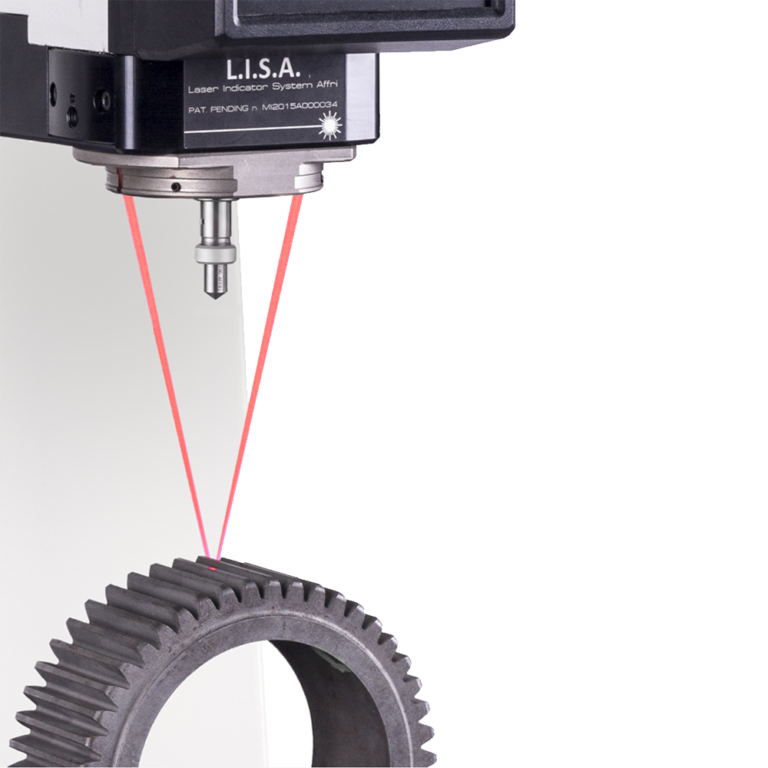

- L.I.S.A – Laser Indicator System Affri (Patented) This exclusive technology provides ultra-precise test positioning, ensuring optimal accuracy. The dual laser pointing system effectively defines the indentation area and distance prior to the indenter's contact with the specimen. It allows for precise measurement in challenging conditions, such as reaching extreme points with poor lighting, edges of gear teeth, or the sides of cutting tools and blades. The system enhances the ability to target difficult-to-reach areas, ensuring accuracy even in complex geometries. (This application is optional for enhanced versatility and precision.)

- SAMPLE ILLUMINATION BY LED The adjustable LED light source ensures a clear and detailed view of the test area, regardless of the surface or specimen shape. It effectively illuminates challenging points with low light conditions, such as sample holes, dark layers, or intricate geometries. The flexible arm allows for versatile positioning, enabling the light to be directed outside of the testing area when needed. This feature guarantees consistent visibility, improving test accuracy. (LED light is optional, providing additional flexibility and precision for various testing environments.)

AFFRI 250 DRM

Motorized Rockwell Hardness Tester

AFFRI 250 DRM Rockwell Hardness Tester is a semi-automatic, user-friendly device designed for precise hardness testing across various scales, including HRC, HRB, HRA, and other specialized scales, with test loads ranging from 3 to 250 kgf. This versatile tester is capable of performing Rockwell, Superficial Rockwell, and Brinell HBWT hardness tests. It is fully compliant with all relevant international hardness testing standards, such as ASTM E10 – E18 and ISO 6506 – 6508, ensuring accurate and reliable results for a wide range of materials.

- Test loads from 3 to 250 kgf (From 29,42 to 2452 N)

- Rockwell and superficial Rockwell ISO 6508 / ASTM E-18 HRA – HRB – HRC – HRD – HRF – HRG – HRL – HRM – HRR / HRN – HRT

- Brinell HBWT ASTM E-103 / ISO 6506 HB 30 – HB 10 – HB 5 – HB 2,5 – MPa (F/D2)

- Vickers ISO 6507 / ASTM E-92 (Indentation only) HV3 – HV5 – HV10 – HV15 – HV20 – HV30 – HV50 – HV100

AUTOMATIC HARDNESS TESTER

250 DRM is a fast and exceptionally easy-to-use bench hardness tester that meets high-accuracy standards. To begin testing, simply adjust the elevating screw to bring the sample into contact with the indenter. Then, press the start button to automatically initiate the preloading and loading process. Within moments, the results are displayed on the screen. Load forces are applied electronically via load cells, eliminating the issues commonly associated with traditional dead-weight systems. This advanced system is unaffected by external vibrations and doesn’t require leveling, ensuring consistent performance in a variety of environments. The intuitive design allows operators of any experience level to perform tests efficiently. With its reliable operation, quick setup, and minimal maintenance, the 250 DRM is ideal for precise hardness testing in both laboratory and industrial settings, providing fast, accurate results every time.

MAIN CONTROL LCD PANEL

Allows for the selection of various hardness scales, adjustment of dwell time, and management of conversion data. Features include a return stroke function, result memory and storage, statistical analysis, and the measurement of test temperature. The system supports calibration and self-diagnostics for routine checkups. It offers configurable tolerance limits, in-process averaging of results, and compensation for measurements on curved surfaces. Automatic evaluation of test outcomes ensures precise and consistent measurements. This suite of advanced functionalities enhances the accuracy, efficiency, and reliability of the testing process across diverse applications.

Only 3″ for one hardness test! (more with standardized dwell time)

EXTRA FEATURES

- L.I.S.A – Laser Indicator System Affri (Patented) This exclusive technology provides ultra-precise test positioning, ensuring optimal accuracy. The dual laser pointing system effectively defines the indentation area and distance prior to the indenter's contact with the specimen. It allows for precise measurement in challenging conditions, such as reaching extreme points with poor lighting, edges of gear teeth, or the sides of cutting tools and blades. The system enhances the ability to target difficult-to-reach areas, ensuring accuracy even in complex geometries. (This application is optional for enhanced versatility and precision.)

- SAMPLE ILLUMINATION BY LED The adjustable LED light source ensures a clear and detailed view of the test area, regardless of the surface or specimen shape. It effectively illuminates challenging points with low light conditions, such as sample holes, dark layers, or intricate geometries. The flexible arm allows for versatile positioning, enabling the light to be directed outside of the testing area when needed. This feature guarantees consistent visibility, improving test accuracy. (LED light is optional, providing additional flexibility and precision for various testing environments.)